azibux1

Registered User

- Joined

- Apr 3, 2013

- Messages

- 2,077

- Reaction score

- 2,646

- Points

- 113

Hi all,

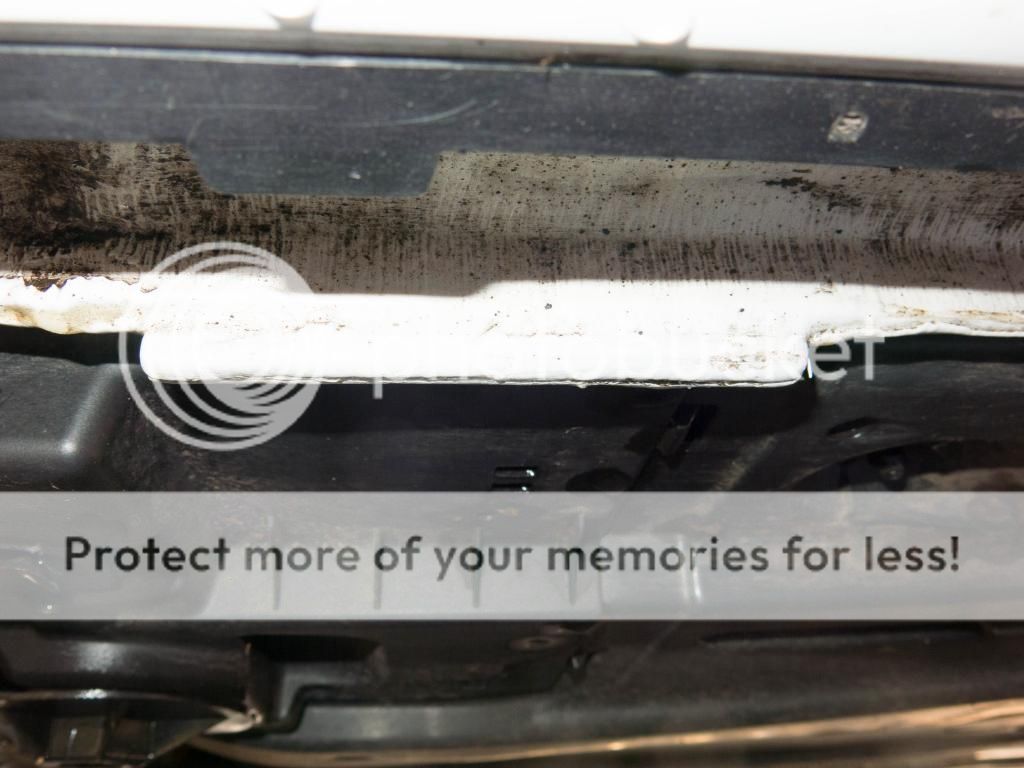

Please can you take a look at the pics and let me know if I jacked it in the right place? This was the rear of the car.

Only asking because it is usually a "pinch weld" (think that's the term) on previous cars I've had where that particular part of the sill / chassis is thinner.... Whereas this was in line with the arrow on the bumper but the metal part there actually got fatter instead and the jack seemed to sort of 'dent' this soft surface a bit... Seemed like metal maybe coated with something to stop the jacking point getting ruined though

Just wanted to check

Thanks!

Please can you take a look at the pics and let me know if I jacked it in the right place? This was the rear of the car.

Only asking because it is usually a "pinch weld" (think that's the term) on previous cars I've had where that particular part of the sill / chassis is thinner.... Whereas this was in line with the arrow on the bumper but the metal part there actually got fatter instead and the jack seemed to sort of 'dent' this soft surface a bit... Seemed like metal maybe coated with something to stop the jacking point getting ruined though

Just wanted to check

Thanks!