Two days before mapping (Thurs 16th April) I went ahead with fitting my new NGK BKR7E plugs....

Unfortunately I had a heart sinking moment....

Plug snapped leaving the thread down the bore and the ceramic part out.... Gosh I nearly went crazy....

After some advise from a few including Paul (Tuffty)... I decided to go for the stud screw remover...

So managed to finish work early on the Friday so I could source a stud remover kit and hope for the best....

Got home and proceeded to begin. Slowly I started screwing the remover into the centre of the plug thread... Then it began to stiffen, and all of a sudden went loose.... Started to panic thinking has it now started to eat away creating metal fillings that now have fallen into the top of the piston....

So just kept screwing until it was completely loose... Slowly I lifted my extension bar to reveal this...

Fully intact.... No damage to threads... No damage to top electrode and nothing fallen down the bore....

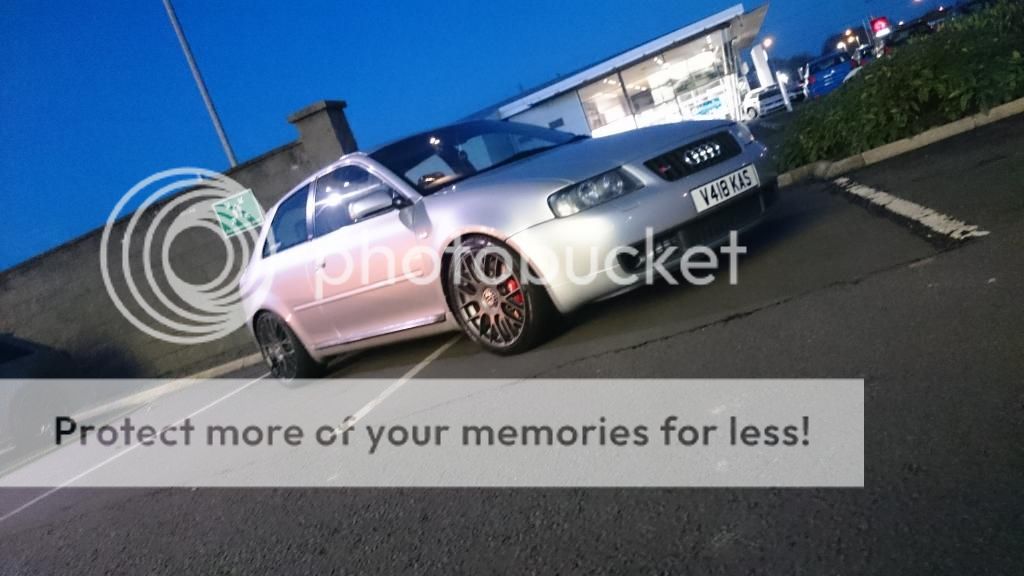

I was gobsmacked, and overwhelmed with joy as I knew now where I was going the next day....

BADGER5

Unfortunately I had a heart sinking moment....

Plug snapped leaving the thread down the bore and the ceramic part out.... Gosh I nearly went crazy....

After some advise from a few including Paul (Tuffty)... I decided to go for the stud screw remover...

So managed to finish work early on the Friday so I could source a stud remover kit and hope for the best....

Got home and proceeded to begin. Slowly I started screwing the remover into the centre of the plug thread... Then it began to stiffen, and all of a sudden went loose.... Started to panic thinking has it now started to eat away creating metal fillings that now have fallen into the top of the piston....

So just kept screwing until it was completely loose... Slowly I lifted my extension bar to reveal this...

Fully intact.... No damage to threads... No damage to top electrode and nothing fallen down the bore....

I was gobsmacked, and overwhelmed with joy as I knew now where I was going the next day....

BADGER5