Well it's been ages since I've made an update and that is because well... It's been ages since anything has happened.

But this week we have been working flat out on the car and have some exciting updates.

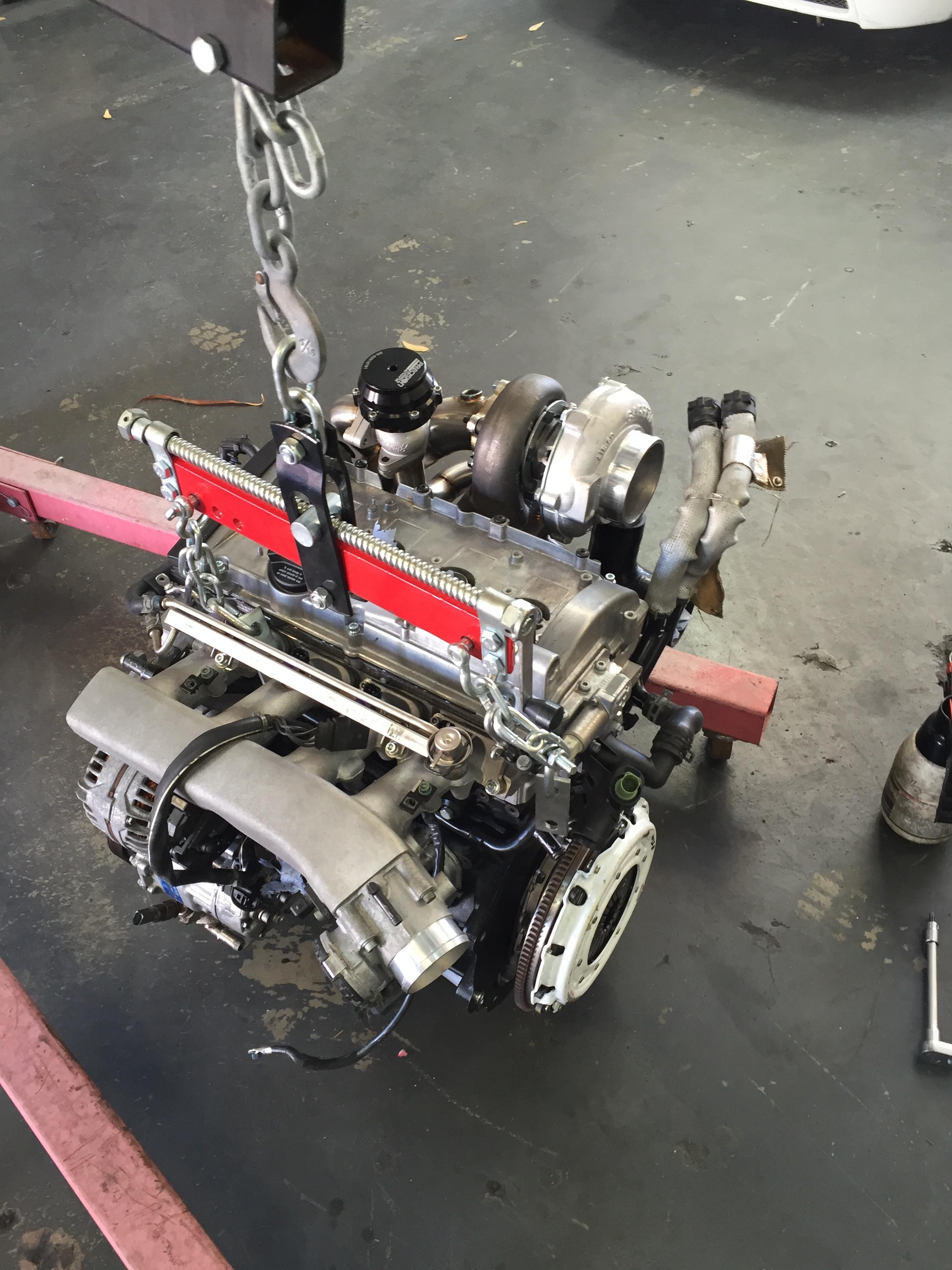

Started by bolting everything up to the engine including the clutch and all accessories

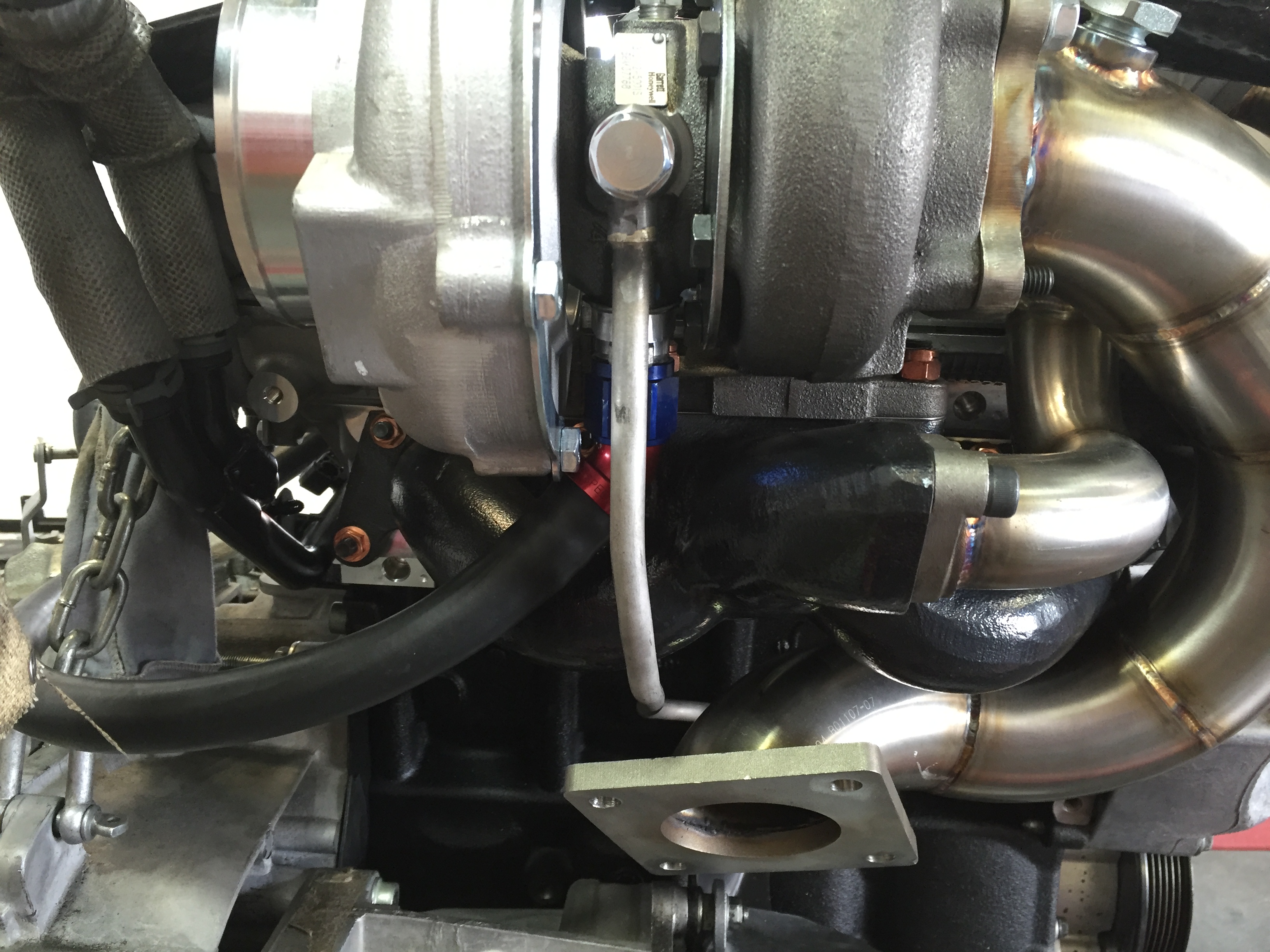

Used silver solder to make a hard line on the coolant return line for added heat resistance over a hose (idea stolen from Tuffty). You can also see the oil return line. This is a push lock hose and has since had substantial heat protection added.

The factory heat exchange has been removed and an external oil cooler will be used running an inline thermostat

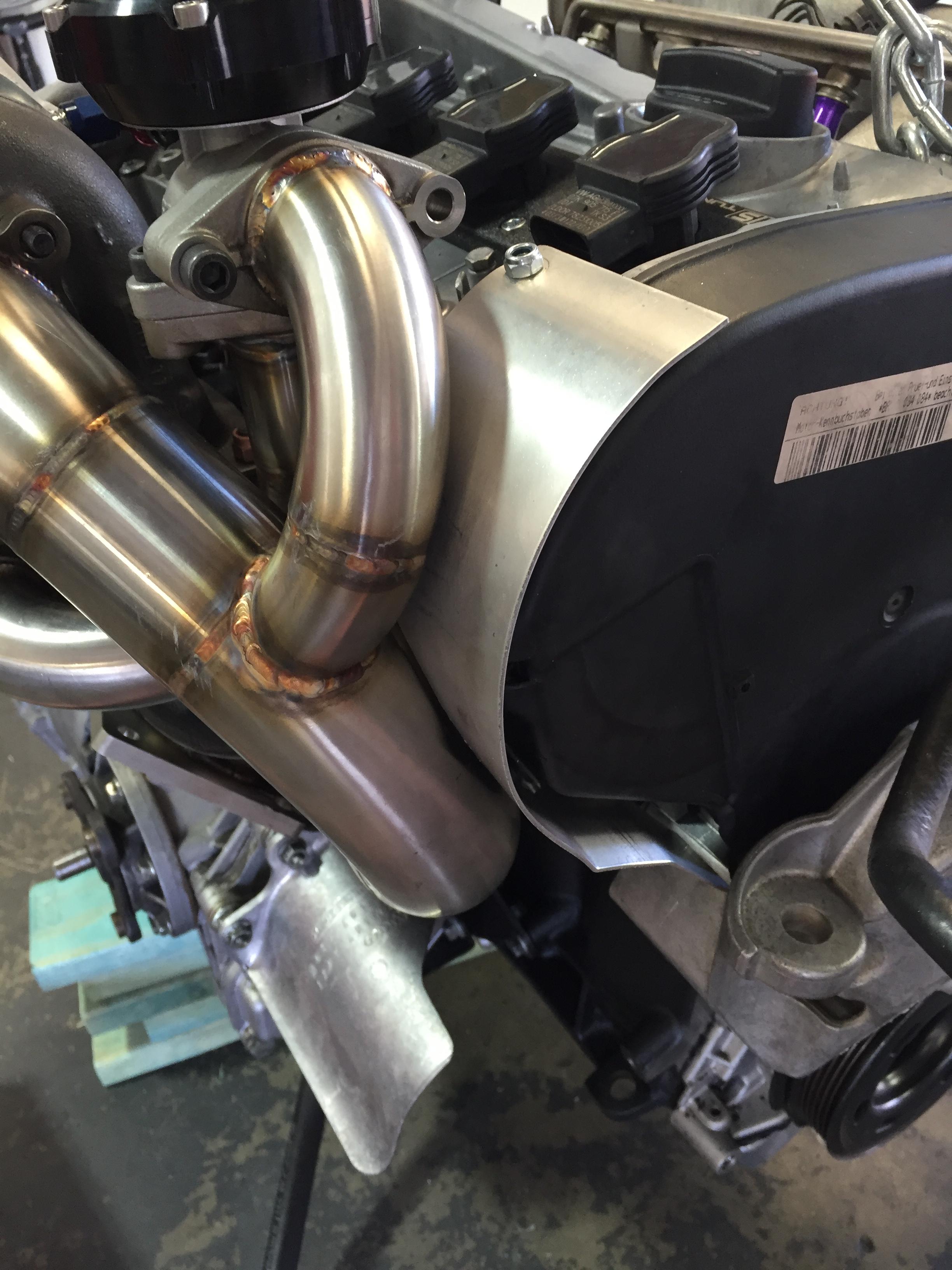

An aluminium heat shield was made to protect some plastic (I expect it may still melt a little)

The engine was test fit and a little panel beating done for some added clearance (once we attached the dog bone we realised this wasn't entirely necessary).

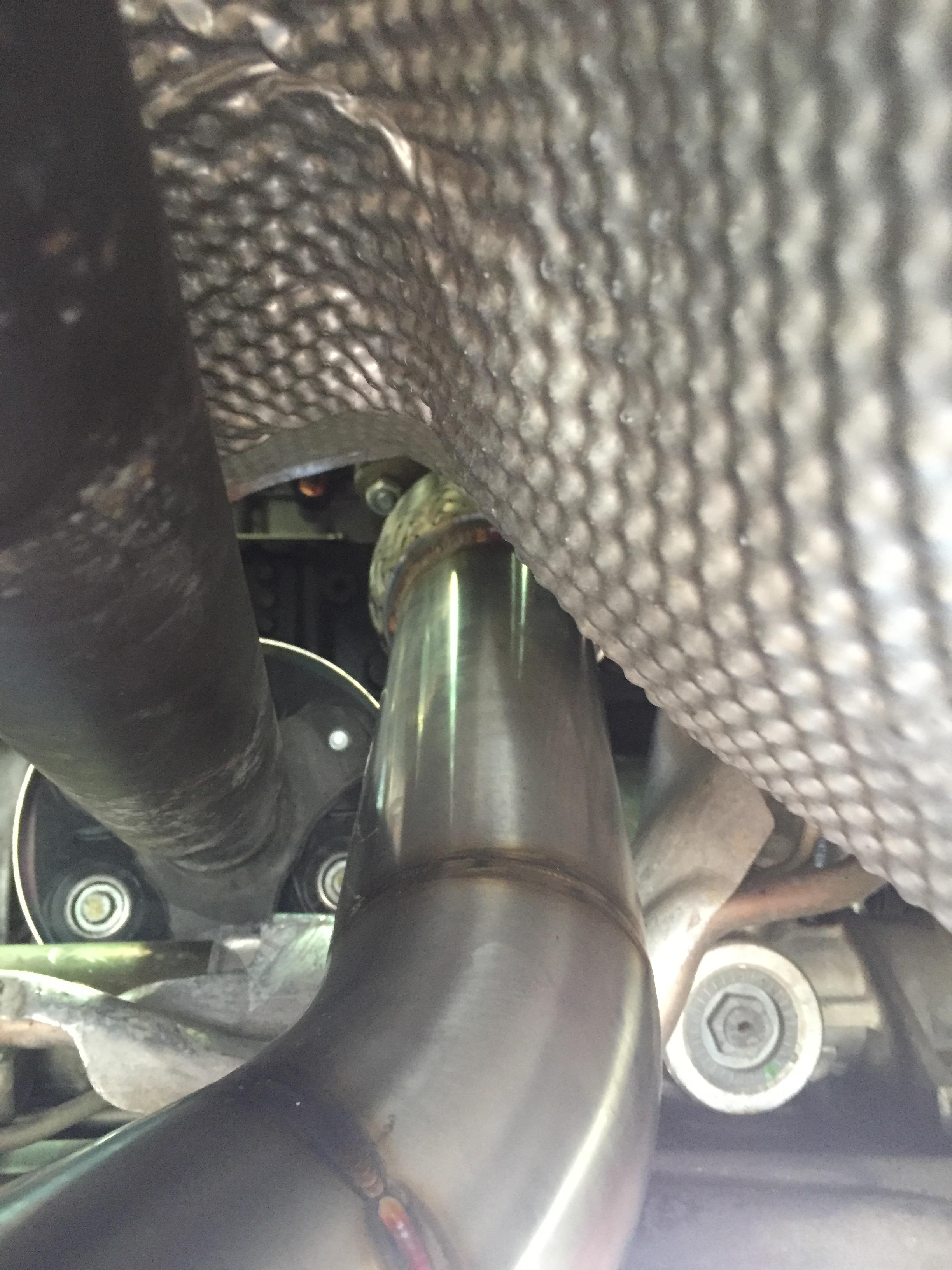

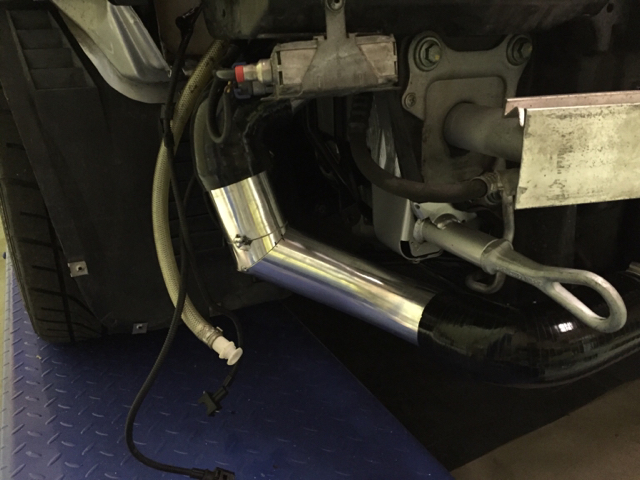

I had to make and weld on a bung for the EGT sensor. This was freightning as my welding skills are all self taught and I didn't want to ruin my down pipe.

My welding is the one on the right (it didn't turn out too bad if you ask me)

Today we will bolt the engine in for good, make a few new hoses, just need to wait on some parts before we attach the drive shafts as we are refreshing some of the old rubber.

I did wonder if you'd abandoned the build as it's been a while,

I did wonder if you'd abandoned the build as it's been a while,

I did wonder if you'd abandoned the build as it's been a while,