Hi Guys,

The date has been finalised and I am starting work on my Audi S3 build Wednesday the 1st of July. So I figure I may as well start a build thread. I'm doing things a little bit differently than other people on the forum. Below is a list of the spec of my car, and I will take photos as I go so people can see the parts I'm using.

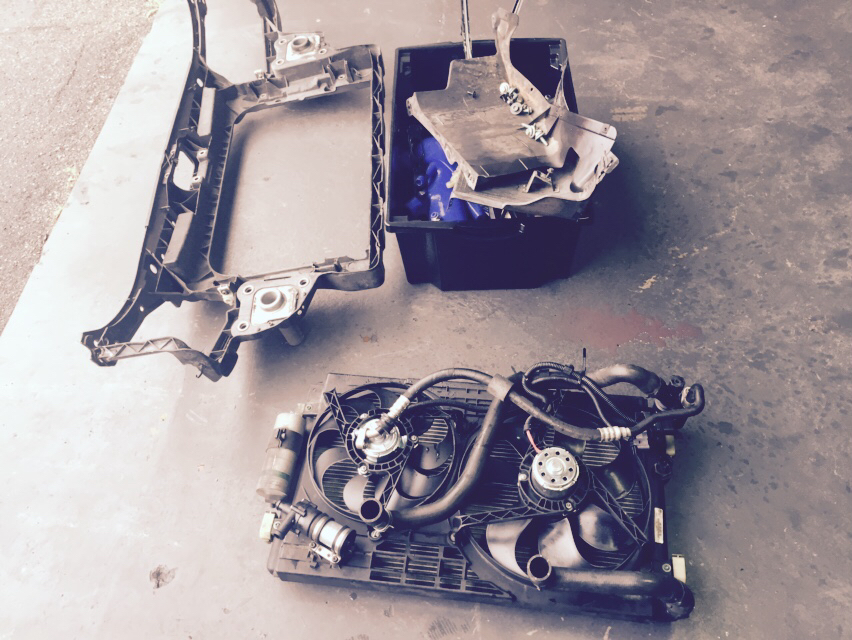

Here is a photo of most of the stuff. Still waiting for valves, cams, ID2000 injectors, ARBs, radiator and a few other misc items.

Build Spec:

Suspension:

Engine:

I know some of the choices regarding components wont be the most popular but each to their own.

If anyone has any insight on using WMI with e85, and specifically what ratio of meth/water works best I would love for you to give me some input. Due to me living in Australia it gets very hot, so the WMI is just to keep intake temps reasonable on hot days. It's not something I will use every day.

The date has been finalised and I am starting work on my Audi S3 build Wednesday the 1st of July. So I figure I may as well start a build thread. I'm doing things a little bit differently than other people on the forum. Below is a list of the spec of my car, and I will take photos as I go so people can see the parts I'm using.

Here is a photo of most of the stuff. Still waiting for valves, cams, ID2000 injectors, ARBs, radiator and a few other misc items.

Build Spec:

Suspension:

AP Coilovers

H&R ARB's (25mm front, 21mm rear)

KW Adjustable rear tie arms

Superpro poly bushes throughout

FK Drop links

Brakes:H&R ARB's (25mm front, 21mm rear)

KW Adjustable rear tie arms

Superpro poly bushes throughout

FK Drop links

ECS Stage 3 front brake kit

ECS Stage 1 rear brake kit

ECS Stage 1 rear brake kit

Engine:

Mishimoto Radiator (tried to get a Direnza but after 4 months didn't have any luck)

Vibratechnics road engine mounts

Garret GTX3071r 63ar T3 flange

CTS Turbo Kit

New custom S/S hardlines and teflon braided hose (oil and coolant lines)

FX400 Ceramic 6 Puck Sprung Disc with Single Mass Steel Flywheel

83mm JE Pistons (9.5:1)

Calico coated bearings, tool steel wrist pins

ARP studs

Full supertech valvetrain, springs & retainers

IE Street cams

ID2000 injectors

Devils own WMI with boost switch and solenoid (unsure if I'll use this due to e85, need to discuss further with tuner)

Forge baffled sump

ECU:Vibratechnics road engine mounts

Garret GTX3071r 63ar T3 flange

CTS Turbo Kit

New custom S/S hardlines and teflon braided hose (oil and coolant lines)

FX400 Ceramic 6 Puck Sprung Disc with Single Mass Steel Flywheel

83mm JE Pistons (9.5:1)

Calico coated bearings, tool steel wrist pins

ARP studs

Full supertech valvetrain, springs & retainers

IE Street cams

ID2000 injectors

Devils own WMI with boost switch and solenoid (unsure if I'll use this due to e85, need to discuss further with tuner)

Forge baffled sump

Vi-Pec elite ECU (plug in and play)

Flex sensor (ability to run any mixture of e85 and 98ron fuel

New AIT sensor to hopefully eliminate heat soak issues of stock sensor

Maf-less tune (will still run a DV, don't want too much attention)

There is much more that I have forgotten and I will add to the list as I go on. If anyone has any questions regarding my build feel free to ask them. I'm all about people giving their opinions as well.Flex sensor (ability to run any mixture of e85 and 98ron fuel

New AIT sensor to hopefully eliminate heat soak issues of stock sensor

Maf-less tune (will still run a DV, don't want too much attention)

I know some of the choices regarding components wont be the most popular but each to their own.

If anyone has any insight on using WMI with e85, and specifically what ratio of meth/water works best I would love for you to give me some input. Due to me living in Australia it gets very hot, so the WMI is just to keep intake temps reasonable on hot days. It's not something I will use every day.

I'm looking forward to see how this turns out

I'm looking forward to see how this turns out