Not a man/company I would ever deal with..

You speak as though you have authority. Here are the facts , you did not have a choice in the matter as we ceased business with you due to your lack of professionalism.

Now back to being ignored.

But you supply a product which Bill has to work with to supply his product...

He actually does not have to do anything with our products as he is not an authorised distributor of our products. The rest is a mute point.

Even more so when I see reputable tuners who have built their name on hard facts and development research (not just you) giving evidence of their poor design

Let these reputable tuners who have purchased a product directly from us that failed come forward. So far only 1 has come forward and it was by association , not direct and the end result was not found to be our fault.

Why don't you use the genuine feedback that he has on the design and pass it to the production and research teams to improve your product?

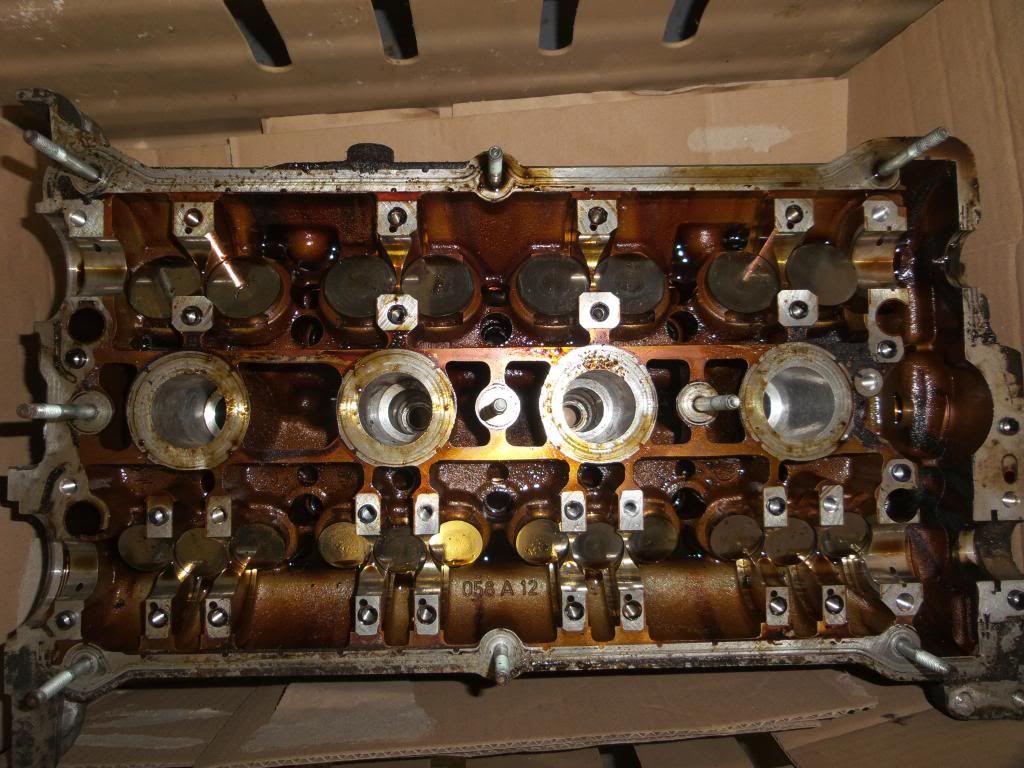

Unfortunately it is not Genuine feedback and the information above was passed onto him by a 3rd party (just like most of the information he posts). The design is not flawed. If it was flawed , oil pressure warning light in the dash would have come on at start up. The channel thickness is in 0.0X" .If the design was flawed it would not have been used in the past by others in the industry.

The individual above has NO PROBLEMS naming and shaming so again :

1. Simon J Wonker (assisted by Ben Parsons) - taken care of by us

2. Mark White - An individual that helps out @ Badger5 purchased connecting rods through someone else (not directly from us) and when his issue arose , we had the entire rotating assembly shipped to JNL Racing where the determined fault of failure had NOTHING to do with the connecting rods. In any case Mark came forward , offered apologies and we did our best to help him by supplying him with parts.

we defend the product - we get slagged

we keep quiet - the product still gets slagged.

we repeat information posted in the past - the product gets slagged and we get slagged for doing so

customer cars come in for a "noise" to "reputable shop" - assumption is made that it is from the connecting rods and the product get slagged.

we rebuttle a competitor slagging our product - we get told about advertiser privlages , our attitude is deemed "poor" and we are slagged off.

Help us understand where exactly are we going wrong? Will I have to read about connecting rods were the reason your wheel bearings failed? Where does this stop?

1 customer that had an issue and any other customers that have issues are being taken care of.

Again to recap. Same design , same dimensions , same connecting rod purchased from the same company being sold since 2009. Why all of a sudden now in 2014 after 4+ years the design is "flawed". If you were in our shoes you would have a poor attitude as well.