Busy day...

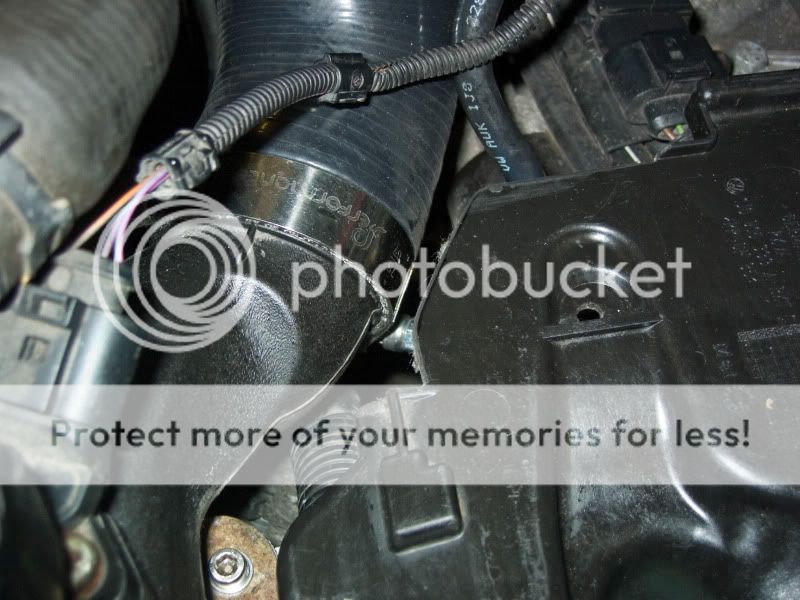

Started by finishing off fitting the AP Racing bolts to the other disc as I only got one done last night. Then moved onto the problem with the hose not fitting the throttle body properly.

Removed the battery and battery tray, undid the MAP sensor tube bracket and loosened up the hoses lower clamp.. essentially fixed it in placed properly top and bottom before attempting to bolt the MAP sensor tube back down. Spaced the bracket up with a couple of stainless steel nuts and bolted it back down... trimmed a bit off the edge of the battery tray so it would not interfere with the MAP sensor tube and jobs a good un...

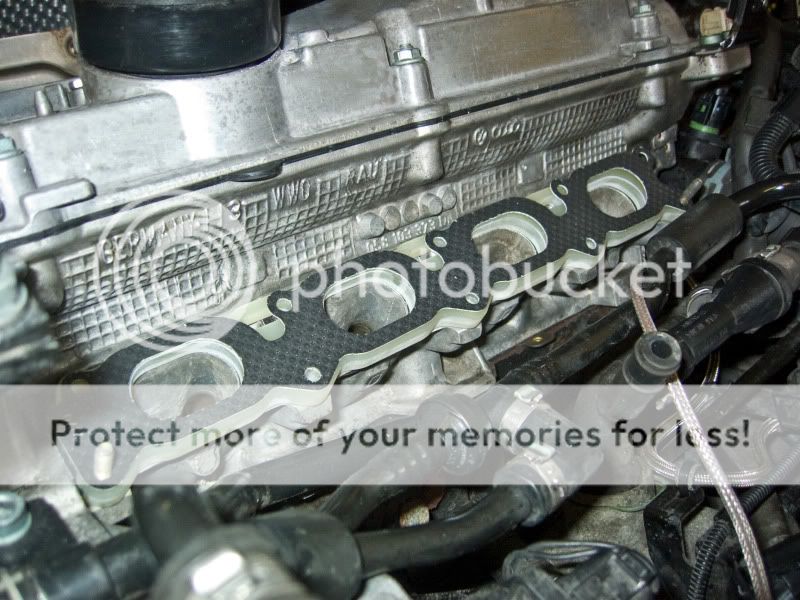

Next I fitted the new injectors to the fuel rail

New 630cc injectors top, S3 bottom

Fitted...

As the 630's are taller, spacers were required to raise the fuel rail...

Wiring reached fine so no need to lose the OE fixtures. I did take the opportunity to re-loom the replacement knock sensor 1 wiring I replaced as I was getting fault codes indicating the wiring was at fault and taped it properly into the loom running it through some flexi conduit along with boost gauge hose. All nice and neat... engine bay is coming back together nicely...

Next job was the fuel filter relocation. Luckily, Bill had a load of hoses he ripped out of his Ibiza so I had a load of OE push fit connectors allowing me to do a neat job of the pipework. Made a bracket and mounted it in..

Test fit...

Used some silicon hose to prevent rubbing etc, final fitment..

I am not 100% happy with this at the moment... I am going to revisit it again once everything else is done with a mind to make a more stable bracket that maybe stands off the engine mount or something... its very tight down there and there are a few hoses in the way so want to make sure its not going to cause any probs being there.

And there we have it. I have one hose clip to refit as I over tightened it (DOH!!) and thats pretty much it for connecting stuff up under the bonnet.

Next job is to wire and plumb in the inline fuel pump, fabricate a TIP, fabricate the DP, rejig the water hose from the block to the turbo as I am not happy with it and look at the oil drain again as it needs a bit of tweaking to ensure it misses the driveshaft.

Bit of mapping to top it off and should all be done

Might be going over tomorrow to remove the rear seats etc for the pump wiring but more likely have a weekend away from it as I am back at work next week and could do with taking some actual time off...

Home stretch now, its been a fairly hectic couple of weeks but nearly done and all is looking good...

Just as a final comparison... here is a pic of the engine bay before I started..

...and how it is now...

<tuffty/>