Hello all,

Not an Audi, but close enough - a Skoda!

I've copied this from another forum, as I'd like a wider scope of help if possible!

Its a 2007 Octavia PD TDI VRS.

I got it cheap knowing it had a misfire, and as I dont get my license back for 8 weeks, something to work on in the mean time.

146k miles, FSH with injector recall done 20k miles ago. New clutch, Flywheel and Master and Slave cylinders. New Injector Loom a few months back too.

DPF delete and remapped, standard engine otherwise.

First off the symptoms -

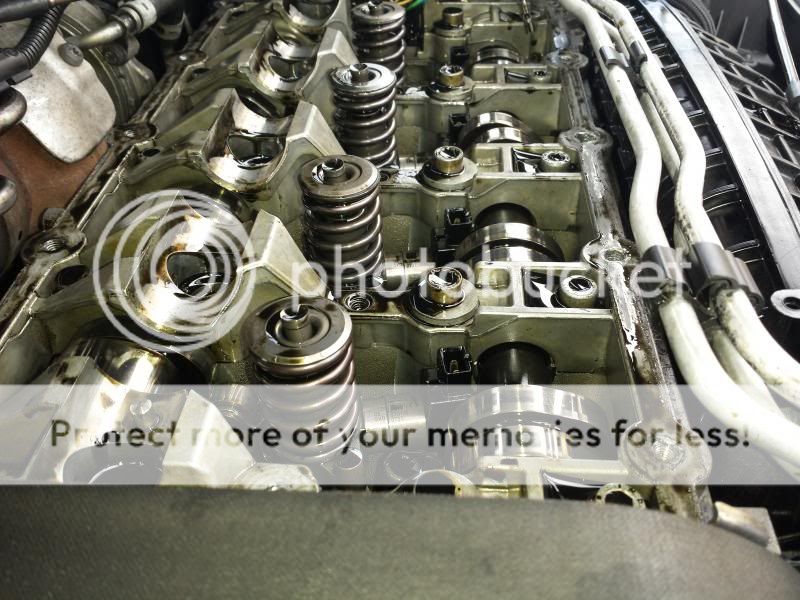

Checking the fuel filter (bearing in mind it was replaced a few months back) and for any contamination in housing:

After about an hour -

Doesn't look too bad. I've definitely seen worse.

--> I then started to check measuring blocks on VCDS at idle:

After a quick rev, and a few seconds to settle:

I then went for a spin (someone else driving) down to the bottom of the road and back, and measured again -

Injector 3 Low voltage -

And switch time deviation (I have no idea what this is) -

And a quick Video that sort of shows the symptoms and turbo whistle (if you turn your speakers up really loud!)

Not an Audi, but close enough - a Skoda!

I've copied this from another forum, as I'd like a wider scope of help if possible!

Its a 2007 Octavia PD TDI VRS.

I got it cheap knowing it had a misfire, and as I dont get my license back for 8 weeks, something to work on in the mean time.

146k miles, FSH with injector recall done 20k miles ago. New clutch, Flywheel and Master and Slave cylinders. New Injector Loom a few months back too.

DPF delete and remapped, standard engine otherwise.

First off the symptoms -

- Most of the time it struggles to start. Once it has fired up it ticks over lovely and smooth for maybe 10 - 30 seconds. Then it starts to miss slightly. Revving it up it revs quickly and cleanly, and without a hitch. Engine visibly rocks, and can sometimes be felt through cabin too.

- Constant smell of unburnt diesel, feels almost strong enough to burn your eyes out! lol. However, visible smoke isn't constant and seems to come and go from the exhaust at tick over, and no noticeable change in engine note when smoke appears. No pattern to smoking either.

- Lack of power! Performance feels flat, and the engine struggles and stutters at higher revs under load. Turbo also whistles more than I'd like.

Checking the fuel filter (bearing in mind it was replaced a few months back) and for any contamination in housing:

After about an hour -

Doesn't look too bad. I've definitely seen worse.

--> I then started to check measuring blocks on VCDS at idle:

After a quick rev, and a few seconds to settle:

I then went for a spin (someone else driving) down to the bottom of the road and back, and measured again -

Injector 3 Low voltage -

And switch time deviation (I have no idea what this is) -

And a quick Video that sort of shows the symptoms and turbo whistle (if you turn your speakers up really loud!)

Last edited by a moderator: