This weeks news:

I turned the engine over by hand randomly as i owed the crank bolt a few degrees. I heard a scratching sound at the gearbox end, so immediately started to panic at what i may have done wrong.

Starter motor came out and it was clear what was wrong:

cover plate was catching the bell housing on the way round, you can see the filings on the cover right where that rivot is.

The black tab you see above had a sharp corner to it, this is what was catching.

So i dremelled all of them to round them off:

Problem solved.

We put this down to manufacture error. Its a LUK clutch. but as far as i know the covers are refurbed with new material, rivots etc, so perhaps a dodgy batch of those black tab things.

This is a better conclusion than fitment error. After a call to my dad about my concerns he came round, and he assured the FW and clutch were installed right as he guided me through it as i used his alignment tool he showed me how to use.

Moving on.

Made some fuel rail spacers out of a bar of alloy.

they're about 13mm. If they dont allow the injectors to seat as snug as they need i can take .5mm off or so.

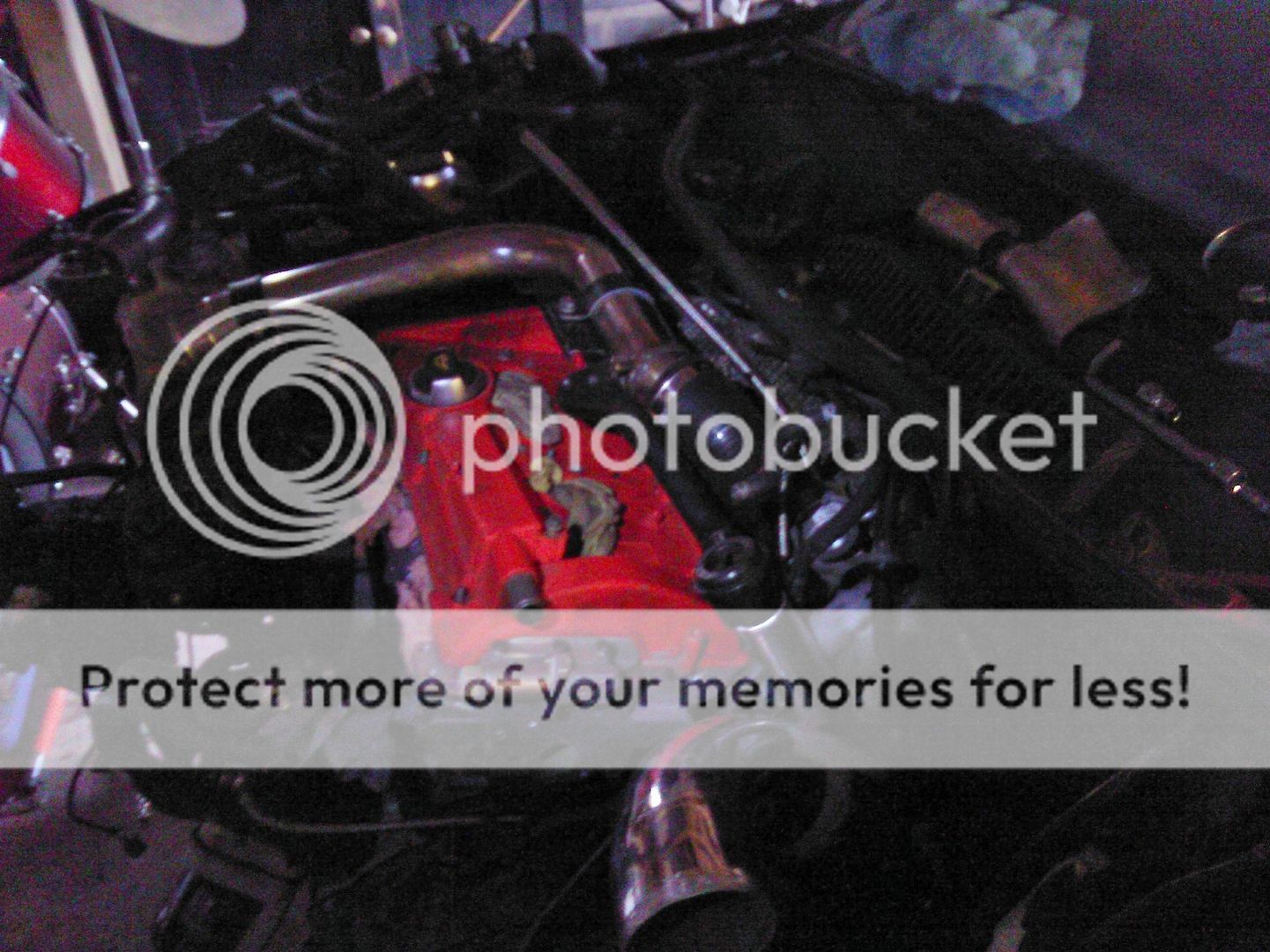

So i fitted the inlet, began installing, plumbing things, and then set about putting the loom in the bay.

took my time with it, making sure i found the right plugs for their sockets, routed everything as nicely as possible.

Engine bay is starting to evolve:

There were a few things i wish i couldve tidied up and shortened etc, but this will have to be done at a much later date if it still bugs me.

And to end, i have a concern:

The alloy union that comes out of the power steering pump, with the hose attached to it as seen above. This was always loose so it could be swivelled around.

Well i realised that it can pull out very very easily, with no way of locking or clamping it in.

This cant be normal surely? I think i may have knocked it while the engine had been on the floor.

Not sure what to do about it.

Going to remove it and see how it works. Bodge it in somehow if need be. Possibly weld it in. I think its on the low pressure side.

Thats all for now.

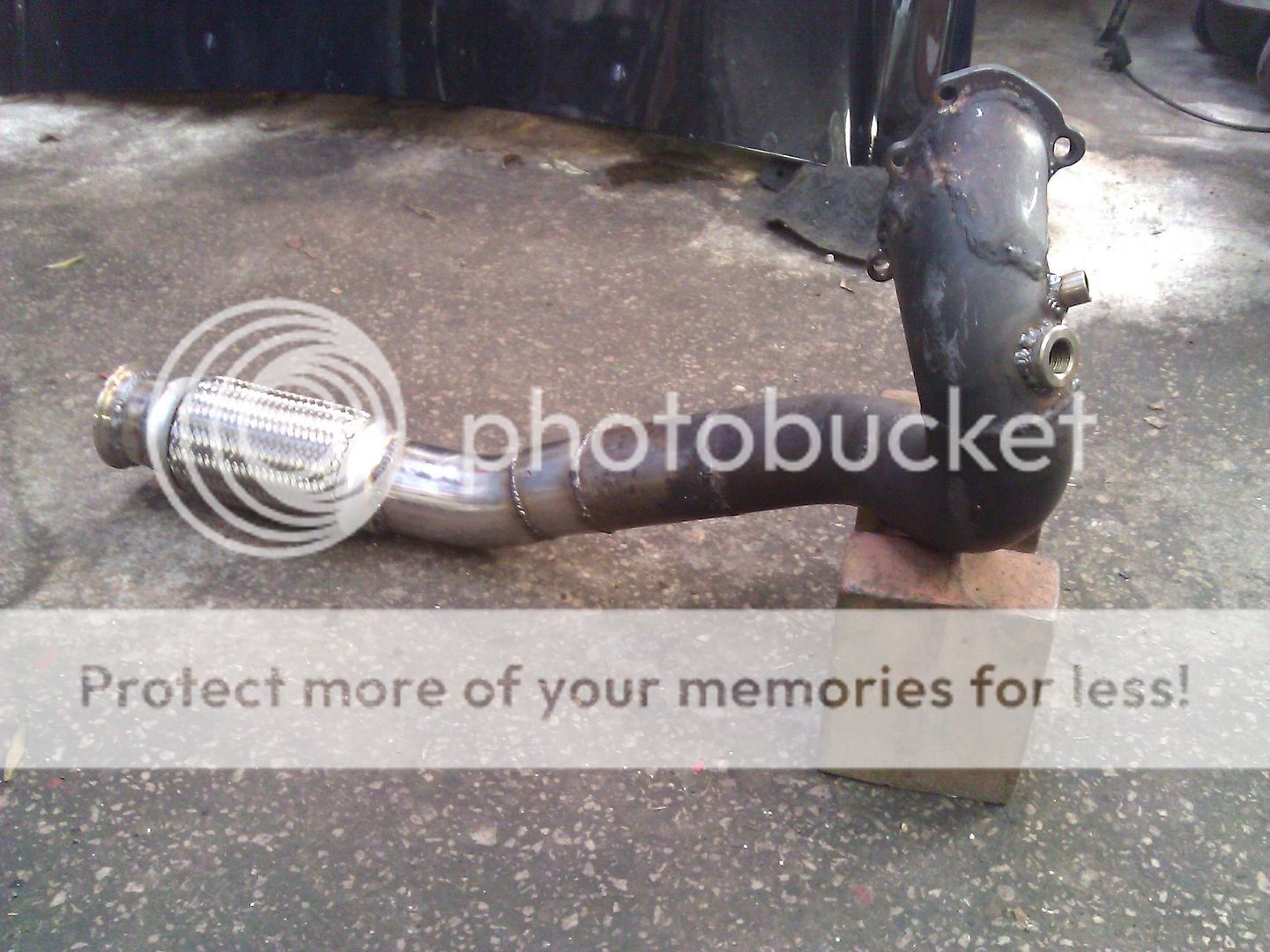

Just got to fit it now, think my dad will give me a hand this saturday getting it all fastened up and in the engine bay once and for all. Heres some pics that i shouldve sent darrens friend to show clearance:

Just got to fit it now, think my dad will give me a hand this saturday getting it all fastened up and in the engine bay once and for all. Heres some pics that i shouldve sent darrens friend to show clearance:

Jobs left:Fasten it all inWire it all inStill havent made fuel rail spacers but shouldnt take more than 30minsTurbo oil drain also needs the other AN fitting putting onTIP Fuel pumpBoost gaugeTaxInsuranceMOT

Jobs left:Fasten it all inWire it all inStill havent made fuel rail spacers but shouldnt take more than 30minsTurbo oil drain also needs the other AN fitting putting onTIP Fuel pumpBoost gaugeTaxInsuranceMOT