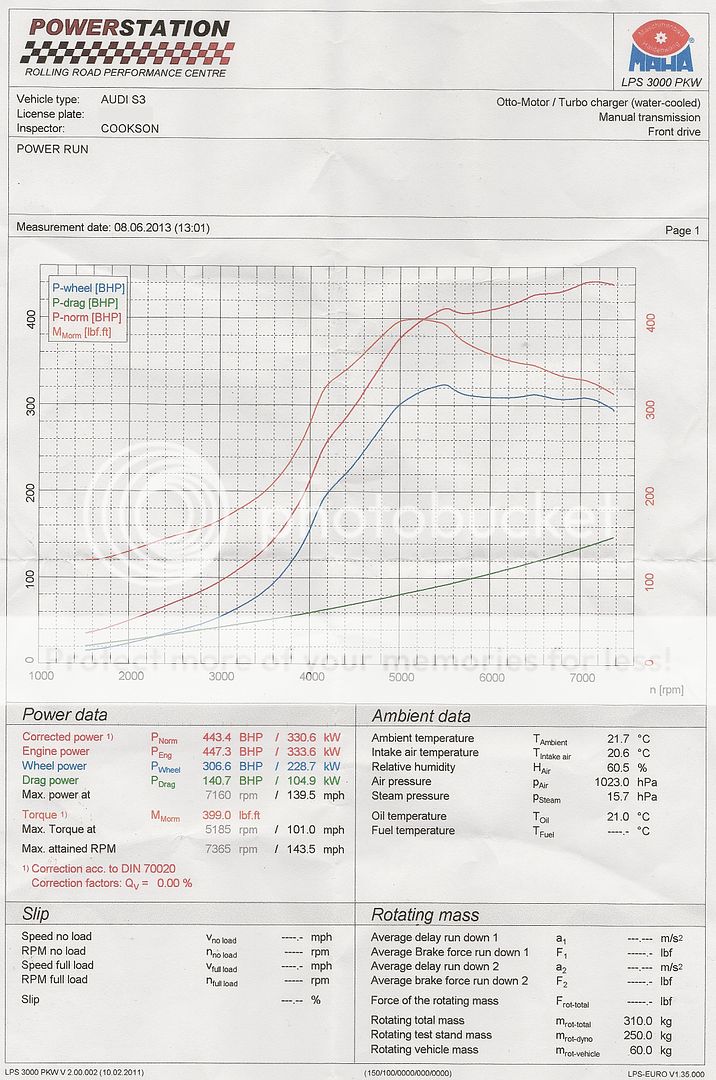

Interesting day out today... went the TT Forums North vs South dyno day at Powerstation...

Bill took the Lupo of course

In preparation of course I cleaned the car... she was looking pretty damn good despite my somewhat epic fail of over wet sanding the **** lacquer job from the 'warranty' paint work I had done...

Over did the bit where the lacquer had peeled away from the original paint and broke through

...so for now I have just slapped some touch up over it and will address it later... despite that the rest came up fine.... ah well

Still she came up ok in the end...

Anyhoo... back to the dyno day... I hadn't intended to run my car but after a little badgering from Hollie and Bill (no pun intended) I ran her up...

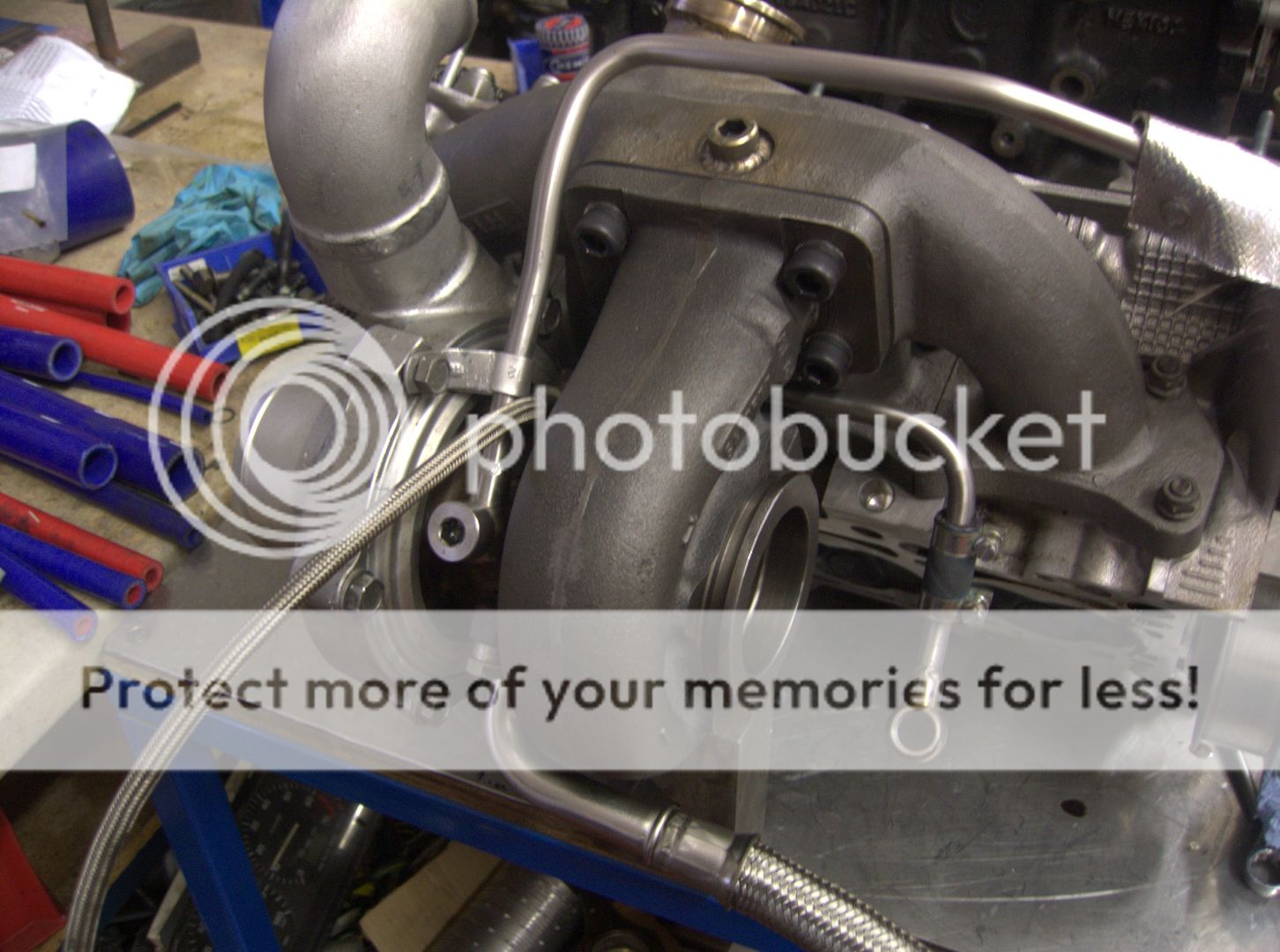

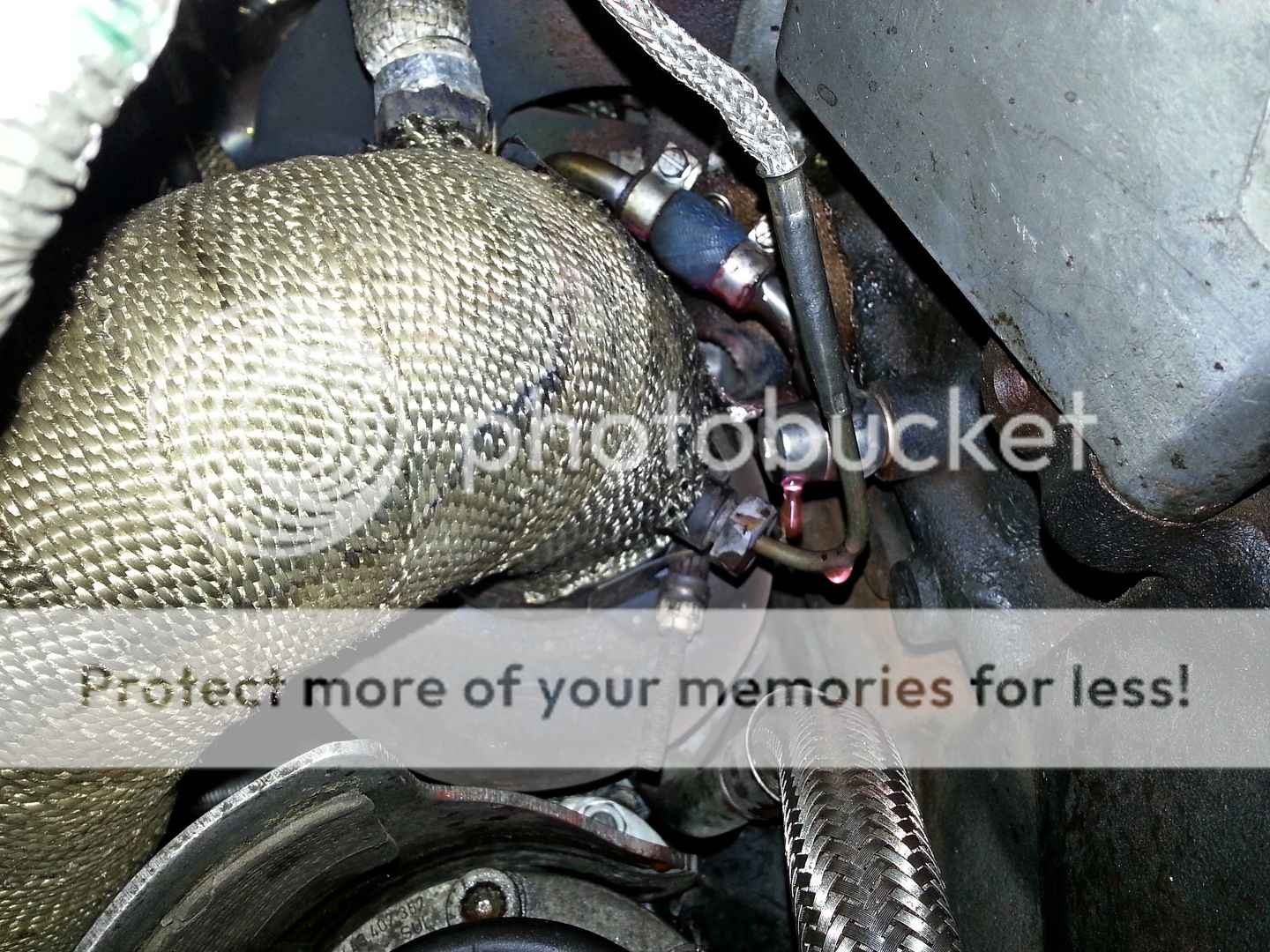

The runs on Powerstations dyno are very long... seems the dyno puts a lot of load on the car as the poor old girl was glowing a good one... for what ever reason they ran the car again and sadly this lead to the coolant hose behind the turbo decided to let go and piddle coolant over the glowing hotstuff... this lead to loads of white smoke and a small fire on the downpipe... marvellous!!!

The pipe in question is a stainless hard pipe but has a high pressure heat resistant rubber section to join the two halves together... (right of the picture below)

Not an easy fix and topping up with water just poured out the bottom again... brilliant!...

Thankfully Bill being the super hero that he is donned his Badger Man outfit and came to the rescue...

Hopefully should be a case of remove driveshaft and downpipe and I'll have access to sort it out...

Cars... gotta love um and todays lesson is (the same as all the others tbh)... heatshielding, heatshielding, heatshielding... anything that is likely to melt probably will

Engine will be out soon for 'some work' so I am going to address some of the issues like this to up the reliability factor...

<tuffty/>