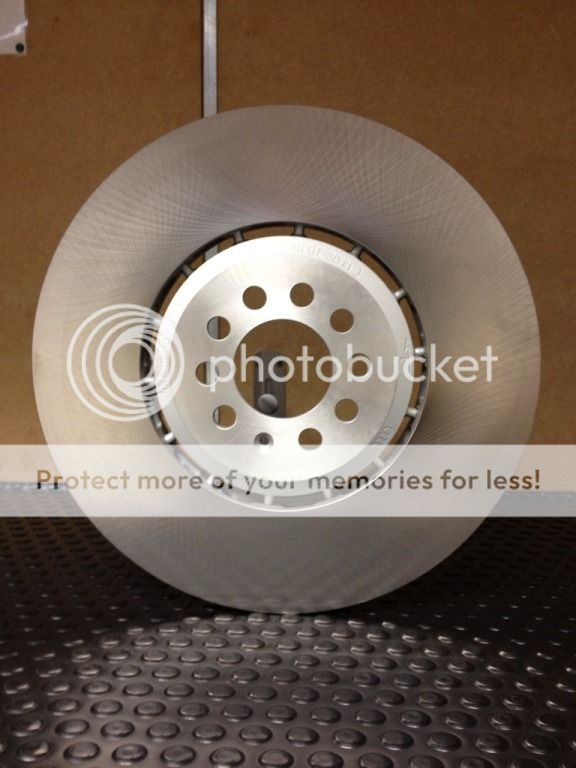

Discs have turned up (cheers jase) although not had a chance to open them yet so no pics

Had a few little niggles with the car this week including blowing off two boost hoses and having a car that ran like ****e, it kept going very lean as soon was coming on boost so drove it like a granny home from London

I was seriously considering breaking it and selling up as all has got a bit much with loads and loads of little problems and faults on the car where it has been neglected due to family and building the engine

I then reset the fault codes on the liquid to clear a reoccurring evap fault and the car felt 10x better

I then gave it some real man boost and started to fall in love again until the front brakes started to judder

Little update

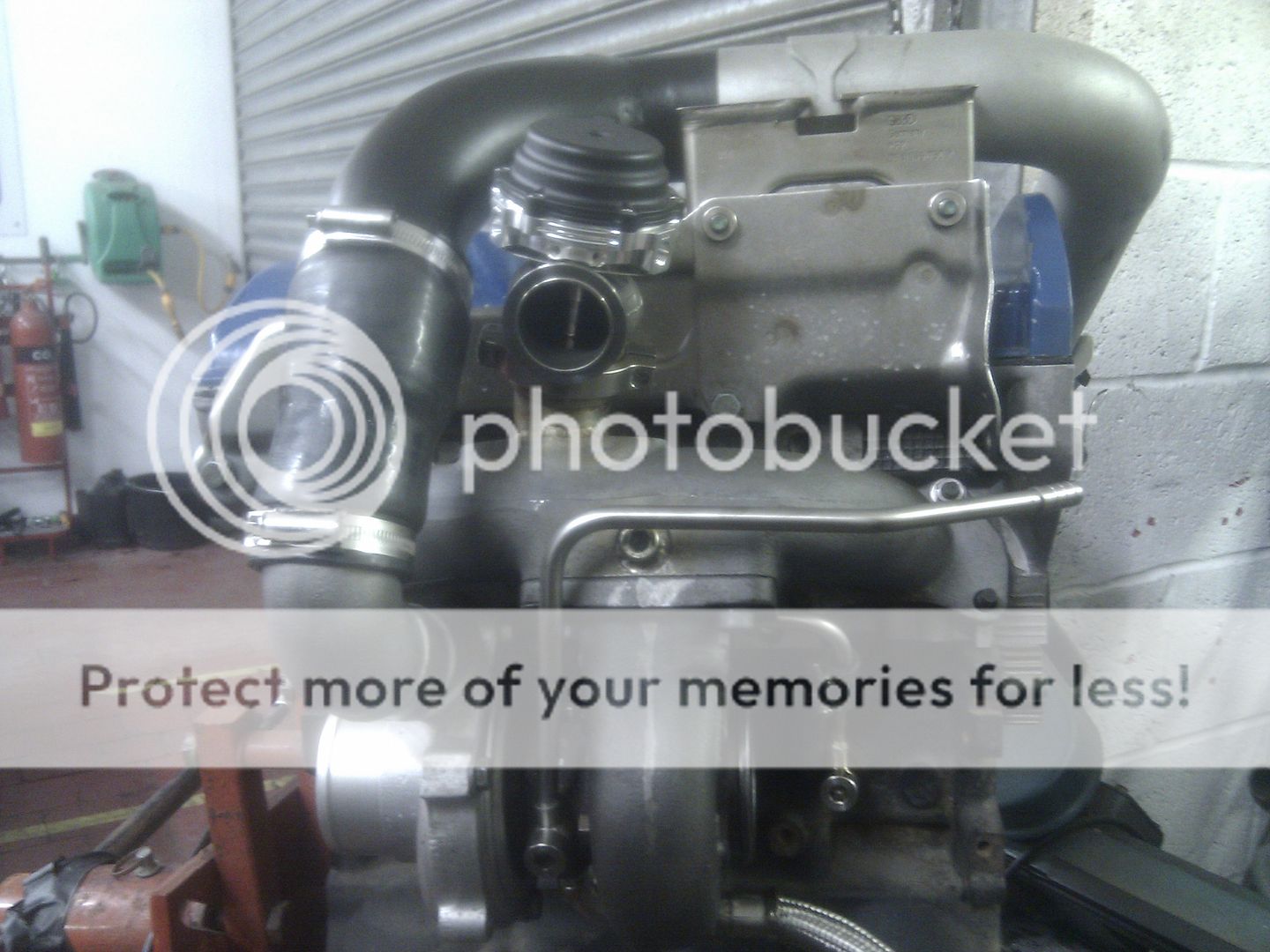

Took the comp cover off to fit a n75 feed, which revealed this beautiful but of art

Machined ally nipple pressed into comp cover

I tried to see if my surge tank would fit where I had hoped but its going to be to tight to get fittings etc on so its back to the drawing board

There's other places that it will fit up front like in the drivers Smic location but would be worried having it in a vulnerable location in event of a crash?

May just run AN lines from the inline 044...will think...umm