I sent them an email which took about 2 minutes. That's all it cost me. I asked them about the revised piston and they said they would send me a service kit out. (I had heard about others getting free kits)

I need to change the spring on mine though, so i might actually have to buy one of them unless anyone else who has bought the springs and doesn't need the others wants some beer tokens..

I need to change the spring on mine though, so i might actually have to buy one of them unless anyone else who has bought the springs and doesn't need the others wants some beer tokens..

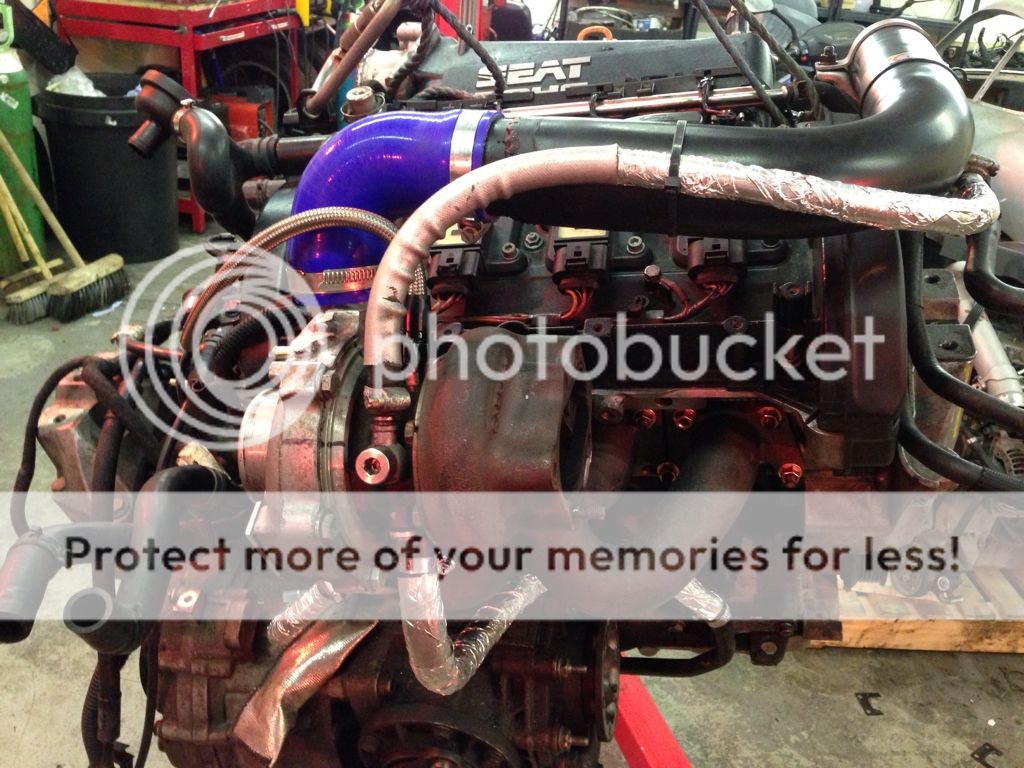

and a couple of the mani bolts didn't want to play ball. The new mani is on, Ben has clocked the turbo and it's set about as good as it can be, charge pipe has been re done and is good to go.

and a couple of the mani bolts didn't want to play ball. The new mani is on, Ben has clocked the turbo and it's set about as good as it can be, charge pipe has been re done and is good to go.