Prawn and BigAls A3 Track Car

- Thread starter Prawn

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

I have built a few 3" turbo back systems, and none of them have exceeded 89db(A) at 4500rpm from new. When they are used for a while they get quieter too.

I'm hoping mine is similar to that Bill, if it isn't, I'll look into adding a 12'' sausage type silcencer like the ones you use on the race cars.

At Goodwood I passed the 100dba static test NO problems at just 86dba on the old system, but I was very close to triggering the drive by monitors at 100dba existing the chicane at the end of the lap.

It's been a day. Where are the logs?

Sorry Doug, I work away from home, so tend to write my updates at the end of a few days at home before going back to work.

I'm home again this evening, and will be doing some logs tomorrow morning to see how it compares to the old engine

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

I'm currently very keen on getting a wideband AFR gauge in the car, with the ME3.8 EcU being prehistoric as we know (****** thing runs on coal!), there's no guarantee that in the event of a problem the car will do anything to protect itself.

Niki advised some time back that when pushing the car any further it would be a good idea to fit one, so I think it's time.

Currently deciding between the AEM UEGO:

AEM Wideband O2 UEGO Gauge - Monitor Air/Fuel Ratio with the Digital 30-4100 - Wideband O2 UEGO, Water/Methanol, Stand Alone Engine Management, Piggyback F/IC, Tru Boost Controller, Gauges, Automotive Performance Electronics

Or the Innovate MTX-L:

MTX-L Wideband O2 Digital Air/fuel Ratio Gauge

I think the AEM wins it though, as I can get one from Xenonlv on ebay, who gave me fantastic service with my AEM WMI kit, it';s AEM which I already have products from, and it lights up red which matches the dials.

Niki advised some time back that when pushing the car any further it would be a good idea to fit one, so I think it's time.

Currently deciding between the AEM UEGO:

AEM Wideband O2 UEGO Gauge - Monitor Air/Fuel Ratio with the Digital 30-4100 - Wideband O2 UEGO, Water/Methanol, Stand Alone Engine Management, Piggyback F/IC, Tru Boost Controller, Gauges, Automotive Performance Electronics

Or the Innovate MTX-L:

MTX-L Wideband O2 Digital Air/fuel Ratio Gauge

I think the AEM wins it though, as I can get one from Xenonlv on ebay, who gave me fantastic service with my AEM WMI kit, it';s AEM which I already have products from, and it lights up red which matches the dials.

- Joined

- Mar 15, 2010

- Messages

- 954

- Reaction score

- 93

- Points

- 28

A wideband gauge is on my list of to buy aswell, though I have been looking at the Stack AFR gauge, partly because (I know this sounds daft) but i want it to match the oil pressure and boost gauges But it also has a programmable alarm to warn of running lean, which could be handy and save having to keep watching the gauge.

But it also has a programmable alarm to warn of running lean, which could be handy and save having to keep watching the gauge.

That AEM one looks good though.

lmao at "too fast and scaring other track users!!!"

But it also has a programmable alarm to warn of running lean, which could be handy and save having to keep watching the gauge.

But it also has a programmable alarm to warn of running lean, which could be handy and save having to keep watching the gauge.That AEM one looks good though.

lmao at "too fast and scaring other track users!!!"

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Y

Yohan87

Guest

Xenonlv on ebay, who gave me fantastic service with my AEM WMI kit, it';s AEM which I already have products from, and it lights up red which matches the dials.

Are the AEM WMI kits he sells (Aem Water Methanol Injection Kit 1 Gallon 3 8L 30 3000 | eBay) the latest version from AEM with the valve issues etc sorted?

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

???...Do we need the Wideband cable

Not sure what you mean by this...

<tuffty/>

???

Not sure what you mean by this...

<tuffty/>

Sorry meant Wideband uego replacement sensor

- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

Sorry meant Wideband uego replacement sensor

Only if you break the one that comes with the gauge

<tuffty/>

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

A few people have had issues with some AEM WMI kits, it seems they might have had a bad batch at some point in the past.

Mine's been absolutely great though, I love it.

Mine's been absolutely great though, I love it.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Cheers for that Paul, even happier I went with the AEM now then

i'm going to be fitting some camber and toe shims tomorow, and wanted some advice.

I'm sorted for the camber, and will be evening out the manufacturing differences and setting it at 2.2 degrees negative on both sides.

For the toe, I currently have 0.17 and 0.26 degrees of toe in. L & R respectively

I have shims for both 0.13 and 0.25 degrees toe change.

Should I fit a 0.13 shim to each side, reducing the toe in but leaving the minor (within tolerance) factory inaccuracy.

Or

Should I fit the 0.13 shim to the LHS bringing it to 0.04 degrees toe in, and the 0.25 degree shim to the RHS bringing it to 0.01 degrees toe in.

Fitting the different shims gives me more even rear geo, but somehow feels wrong.

Any advice?

i'm going to be fitting some camber and toe shims tomorow, and wanted some advice.

I'm sorted for the camber, and will be evening out the manufacturing differences and setting it at 2.2 degrees negative on both sides.

For the toe, I currently have 0.17 and 0.26 degrees of toe in. L & R respectively

I have shims for both 0.13 and 0.25 degrees toe change.

Should I fit a 0.13 shim to each side, reducing the toe in but leaving the minor (within tolerance) factory inaccuracy.

Or

Should I fit the 0.13 shim to the LHS bringing it to 0.04 degrees toe in, and the 0.25 degree shim to the RHS bringing it to 0.01 degrees toe in.

Fitting the different shims gives me more even rear geo, but somehow feels wrong.

Any advice?

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

slappy_dunbar

Let's Do This

- Joined

- Jan 2, 2010

- Messages

- 245

- Reaction score

- 20

- Points

- 18

- Location

- Westchester Cty, New York USA

- Website

- www.frankenturbo.com

I'm currently very keen on getting a wideband AFR gauge in the car...

Been tinkering with this one over here...

Last edited by a moderator:

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

i toe out on badgerwagen

On the back?

I'd be interested to hear what rear camber / toe the badgerwagon runs in dry race trim Bill

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

I would fit what corrects the settings. regardless of them not being a "pair" to me would seem daft to ignore the diffrence if your changing it?

it's not so much correcting you see Paul, it's improving on audi's terrible standard alignment at the back of the FWD car.

It seems they just gave them all a bit of rear camber and a SHED load of rear toe in to make it ultra safe.

v5 tt

Registered User

I'm currently very keen on getting a wideband AFR gauge in the car, with the ME3.8 EcU being prehistoric as we know (****** thing runs on coal!), there's no guarantee that in the event of a problem the car will do anything to protect itself.

Niki advised some time back that when pushing the car any further it would be a good idea to fit one, so I think it's time.

Currently deciding between the AEM UEGO:

AEM Wideband O2 UEGO Gauge - Monitor Air/Fuel Ratio with the Digital 30-4100 - Wideband O2 UEGO, Water/Methanol, Stand Alone Engine Management, Piggyback F/IC, Tru Boost Controller, Gauges, Automotive Performance Electronics

Or the Innovate MTX-L:

MTX-L Wideband O2 Digital Air/fuel Ratio Gauge

I think the AEM wins it though, as I can get one from Xenonlv on ebay, who gave me fantastic service with my AEM WMI kit, it';s AEM which I already have products from, and it lights up red which matches the dials.

Im running narrow band i thought about getting one of these but i think i would prefer to put the

money towards an ECU wideband conversion seen i as got a liquid tt installed in the vent

to get A/F ratio,s

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Been tinkering with this one over here...

That looks amazing Doug, how is that configured onto the standard DIS?

I've been out and taken some logs for you,

The old setup, with 12psi actuator, was peaking 172g/s on Actuator, and 185g/s on full boost.

The new setup, run on actuator at ~15psi

187.15g/s, on actuator pressure! and a few other pulls where I didn't quite rev it out and it's made 185g/s

So, whilst I know it's not conclusive, it's flowing more air now on the actuator than it did previously on full boost.

Also showing zero CF's across the board, and IAT's are nice and low

Very promising indeed!

Last edited by a moderator:

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Worth noting that I'm using an OBD II vr6 MAF housing (80mm OD) with an AGU sensor which is 70mm OD, and all other values are scalled to suit, so my MAF readings are around 38% low from the logs.

The AGU sensor can only read a max of 187g/s with slight corrections for atmospheric conditions, so I've basically maxxed out the sensor on actuator pressure.

This seems a little odd to me, as Niki reckons the AGU sensor in VR6 housing maxes out at 320bhp!

The AGU sensor can only read a max of 187g/s with slight corrections for atmospheric conditions, so I've basically maxxed out the sensor on actuator pressure.

This seems a little odd to me, as Niki reckons the AGU sensor in VR6 housing maxes out at 320bhp!

- Joined

- Nov 11, 2009

- Messages

- 10,099

- Reaction score

- 739

- Points

- 38

- Location

- west yorks

- Website

- www.stainless-engineering.co.uk

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

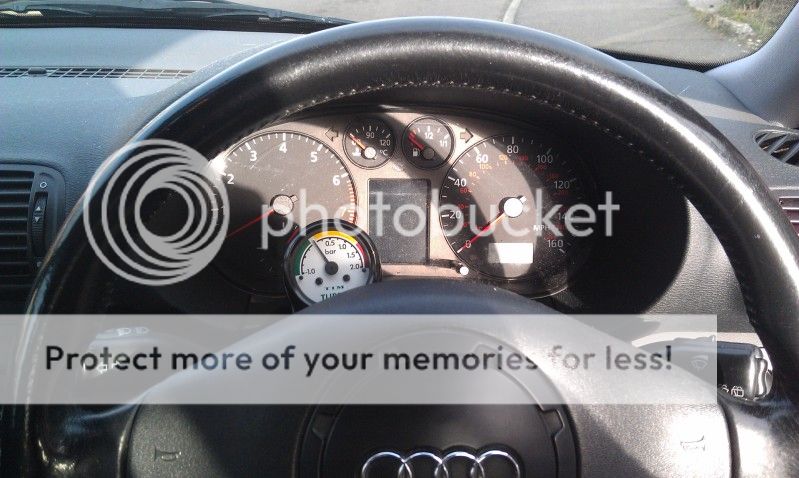

Gauge holder for the AEM AFR has arrived, so I threw an old boost gauge in to try out a few different locations.

I was originally thinking of putting it next to the boost gauge, but then decided it might look crap.

Lining it up there, I think it actually does look OK, and it's line of sight in an area I'm looking anyway:

So this is option 1:

Option 2, on the column, my DIS doesn't work anyway, so I'm not missing much:

And option 3, the least favourite, as it's on it's own there, and I'd have to drill a hole in the dash as I HATE visable cables anywhere:

Thoughts please people?

I was originally thinking of putting it next to the boost gauge, but then decided it might look crap.

Lining it up there, I think it actually does look OK, and it's line of sight in an area I'm looking anyway:

So this is option 1:

Option 2, on the column, my DIS doesn't work anyway, so I'm not missing much:

And option 3, the least favourite, as it's on it's own there, and I'd have to drill a hole in the dash as I HATE visable cables anywhere:

Thoughts please people?

- Joined

- Sep 4, 2003

- Messages

- 29,115

- Reaction score

- 3,862

- Points

- 113

- Location

- Solihull, Midlands

- Website

- www.audi-sport.net

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Cheers Joe, I don't like double pods on the pillars, it just looks too bulky, and I'm proud of this one as I made it

Option 2 is looking king, with the black facia and bezzle on the AEM like this:

Option 2 is looking king, with the black facia and bezzle on the AEM like this:

- Joined

- Sep 4, 2003

- Messages

- 29,115

- Reaction score

- 3,862

- Points

- 113

- Location

- Solihull, Midlands

- Website

- www.audi-sport.net

I'm trying to find a guy called Jarvis, I don't remember his username, he put his boost gauge on his steering column, but he moulded around the gauge to make a custom pod, I'm sure he posted a pic, he drives a LCR.

- Joined

- Sep 4, 2003

- Messages

- 29,115

- Reaction score

- 3,862

- Points

- 113

- Location

- Solihull, Midlands

- Website

- www.audi-sport.net

Found it, he stuck his liquid gauge in there! lol

http://www.audi-sport.net/vb/a3-s3-forum-8l-chassis/132816-a3-8l-liquid-guage.html#post1381502

http://www.audi-sport.net/vb/a3-s3-forum-8l-chassis/132816-a3-8l-liquid-guage.html#post1381502

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Cheers for that Joe, looks smart.

Ok BBD, option 2 it is

I like it on top of the steering column. Looks pro.

Ok BBD, option 2 it is

Prawn, I've recently made a pod for the steering cowling. Like yourself, I'm not keen on the pillar pods. I bought a newsouth pod for a mk4 golf, is perfect position for a gauge, but the newsouth thing doesn't fit properly so I adapted the standard cowling

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Steering column it is  Munch - that looks good mate. I like. I'm going to mount the single on top for now, then if I get any more gauges I'll mount them side by side.

Munch - that looks good mate. I like. I'm going to mount the single on top for now, then if I get any more gauges I'll mount them side by side.

Had a bit of a chill out today and went to Newbury with Tori, bit of shopping and a Costa, then back home and there was still some daylight left, so I decided to make a start on tomorrows work.

I dug these out from my box of new parts awaiting fitment:

And these out of the boot of the car, KW V3's

Quick check on the ride height before stripping it down:

Old dirty Weitecs ready to remove:

and thanks to my impact gun, 10 minutes later it was out:

Eibach offset top mounts built up onto the KW V3's

All threads and the base greased up and ready to fit:

And in it goes:

Turned the car round, now you see it:

Now you don't:

It took literally less than 5 minutes from jacking the car up to having the coilover out - did I mention how AWESOME it is having an impact gun?

KW all stripped down to grease up the threads:

And in it goes:

Very hard to make it show on a picture, but it's made the car look quite different in how the front end sits:

Went for a little drive and all feels great, stuck £30's worth of V power in it and did a few more miles then pulled over on a known level concrete surface and checked the cambers with my phone app:

Not too bad at all, obviously that's just a rough guide, but it's feeling amazing so far. I've set the mount sup to that the caster and camber is increased as much as they can give, so the offset of the topmount is at 45 degrees inwards to the rear. I could give them more caster, or more camber, but this is the most I can get of both together.

And on a totally random and seperate point, Jardo did this little photoshop earlier, which I think looks awesome:

Rear coilovers and camber shims coming tomorrow!

Had a bit of a chill out today and went to Newbury with Tori, bit of shopping and a Costa, then back home and there was still some daylight left, so I decided to make a start on tomorrows work.

I dug these out from my box of new parts awaiting fitment:

And these out of the boot of the car, KW V3's

Quick check on the ride height before stripping it down:

Old dirty Weitecs ready to remove:

and thanks to my impact gun, 10 minutes later it was out:

Eibach offset top mounts built up onto the KW V3's

All threads and the base greased up and ready to fit:

And in it goes:

Turned the car round, now you see it:

Now you don't:

It took literally less than 5 minutes from jacking the car up to having the coilover out - did I mention how AWESOME it is having an impact gun?

KW all stripped down to grease up the threads:

And in it goes:

Very hard to make it show on a picture, but it's made the car look quite different in how the front end sits:

Went for a little drive and all feels great, stuck £30's worth of V power in it and did a few more miles then pulled over on a known level concrete surface and checked the cambers with my phone app:

Not too bad at all, obviously that's just a rough guide, but it's feeling amazing so far. I've set the mount sup to that the caster and camber is increased as much as they can give, so the offset of the topmount is at 45 degrees inwards to the rear. I could give them more caster, or more camber, but this is the most I can get of both together.

And on a totally random and seperate point, Jardo did this little photoshop earlier, which I think looks awesome:

Rear coilovers and camber shims coming tomorrow!

Pdogs, I think you should mount the AFR gauge on the column too. It's the most OEM looking location you've got left.

I did that photoshop with one of these -

By laying the old picture underneath and then using pencil strokes to mimic it. Took ages but was fun, if anybody else wants one done then send me the pic and I'll give it a go

What you doing with the Weitec's? Are the ****ed?

I did that photoshop with one of these -

By laying the old picture underneath and then using pencil strokes to mimic it. Took ages but was fun, if anybody else wants one done then send me the pic and I'll give it a go

What you doing with the Weitec's? Are the ****ed?

slappy_dunbar

Let's Do This

- Joined

- Jan 2, 2010

- Messages

- 245

- Reaction score

- 20

- Points

- 18

- Location

- Westchester Cty, New York USA

- Website

- www.frankenturbo.com

That looks amazing Doug, how is that configured onto the standard DIS?

I don't really understand how this guy can make it work. But it involves inserting a control box between the car's harness and the gauge cluster. Here's a link to the photos I took while installing it.

I've been out and taken some logs for you,

The old setup, with 12psi actuator, was peaking 172g/s on Actuator, and 185g/s on full boost.

The new setup, run on actuator at ~15psi

187.15g/s, on actuator pressure! and a few other pulls where I didn't quite rev it out and it's made 185g/s

So, whilst I know it's not conclusive, it's flowing more air now on the actuator than it did previously on full boost.

Also showing zero CF's across the board, and IAT's are nice and low

Very promising indeed!

Worth noting that I'm using an OBD II vr6 MAF housing (80mm OD) with an AGU sensor which is 70mm OD, and all other values are scalled to suit, so my MAF readings are around 38% low from the logs.

At first I was really disappointed by those numbers. But the fact that they're skewed by the sensor/housing mismatch explains everything. I have a spreadsheet which studies the voltage response of these sensors. It works out that the scaling factor changes slightly as airflows increase. It starts out at a 1.38/1 ratio but drops to 1.30/1 by 5000rpms or so. So, realistically, your actual flows are somewhere around 185 x 1.30 = 240 g/s.

That is really solid performance at 1bar of pressure.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Thanks Doug, would you be able to share that spreadsheet with me? I was working on the 1.38 rule for scaling, but it would put my maf readings in at 258g/s in Real terms, which I thought sounded TOO high at this stage. 240g/s sounds much more realistic, and ties in with Niki seeing just over 300bhp at 1 bar on the old setup also.It'll be on the dyno at Bills in a week anyway, so we'll have a better idea then, and when I get the chance and some time off work ill head back up to Rtech and we'll see what it can really do!

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Believe me, if it was making a genuine 187g/s after all this work of have burnt it to the grounding agoAt first I was really disappointed by those numbers. But the fact that they're skewed by the sensor/housing mismatch explains everything.