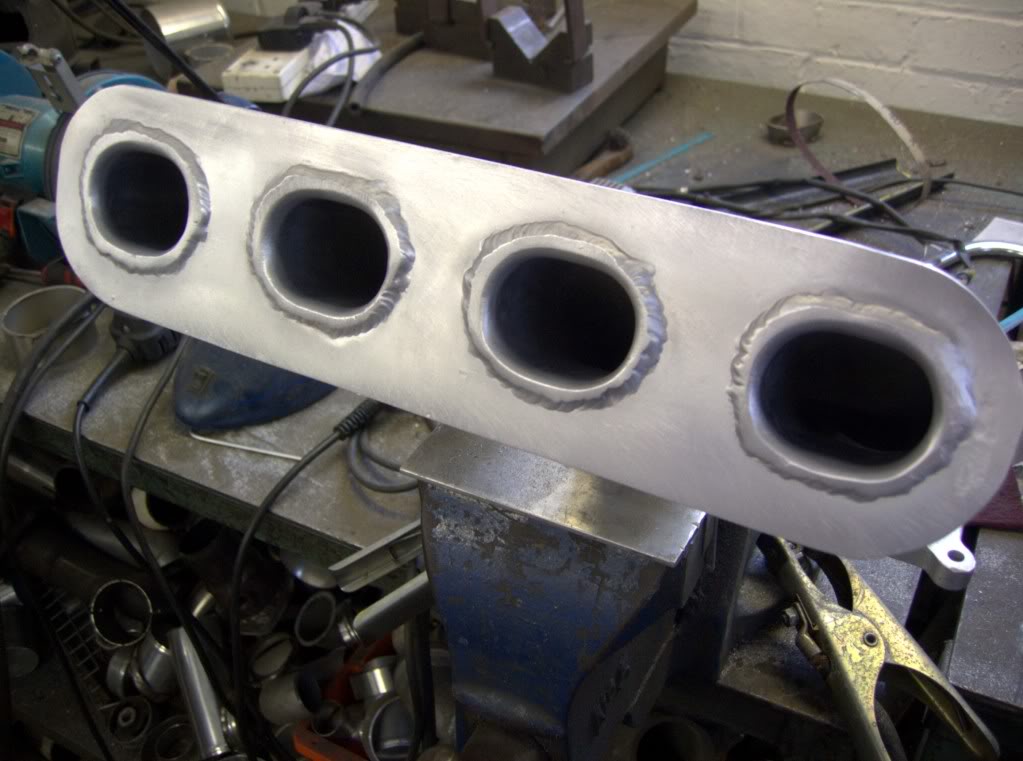

Took advantage of a decent evening to sort out my wastegate base pressure... currently under 'actuator' pressure (there isn't an actual actuator on an external wastegate) I see 9psi (0.6bar) which is not really enough on a setup like mine...

I couldn't remember what spring was in it so I grabbed a few off the shelf at Bills and hoped I would have enough to set it all up properly...

I used this chart for reference...

Removed the strut brace and charge pipe to get to the Tial... thankfully even though my turbo is a bit trickier to get too than a top mount turbo the wastegate is a bit easier

Now the fun begins... anyone who has done this on a Tial will know what a **** of a job it is... its bad enough when the thing is off on the bench but I did mine in situe.. the little caps screws all come undone and the spring pressure is quite a shock...

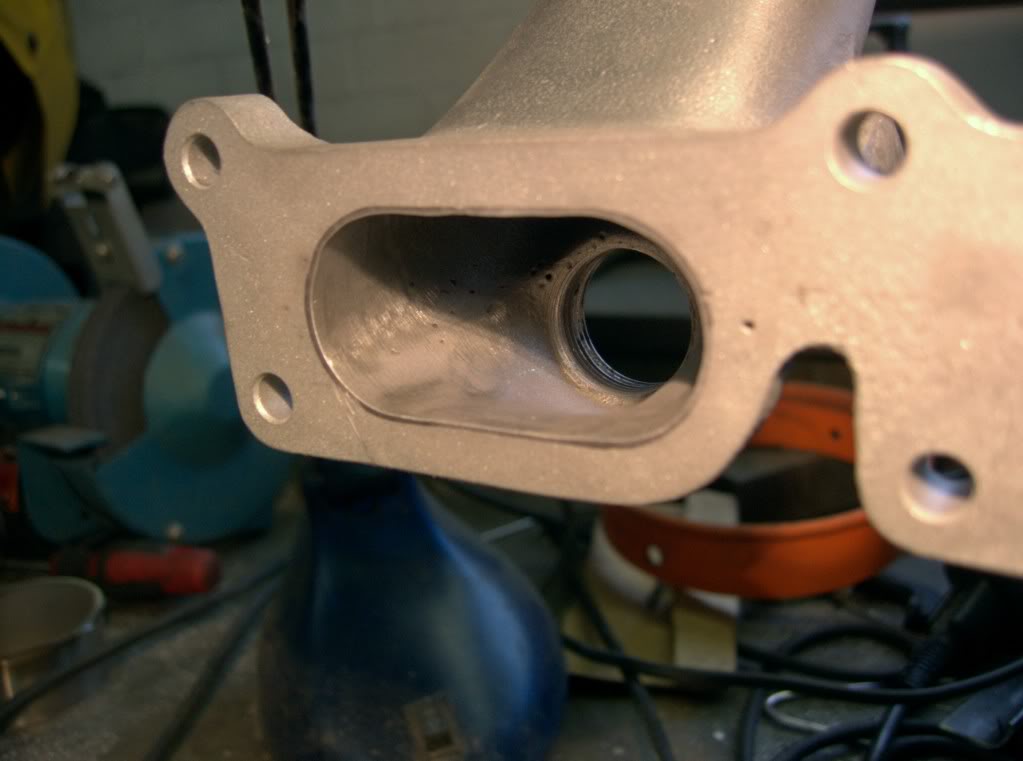

I had a copper spring in there which is rated at 0.5bar for the MVS at 1:1 pressure ratio... as most pressure ratio's a re a little higher than that mine obviously gained a little from that... so about 2psi up on the actual rating...

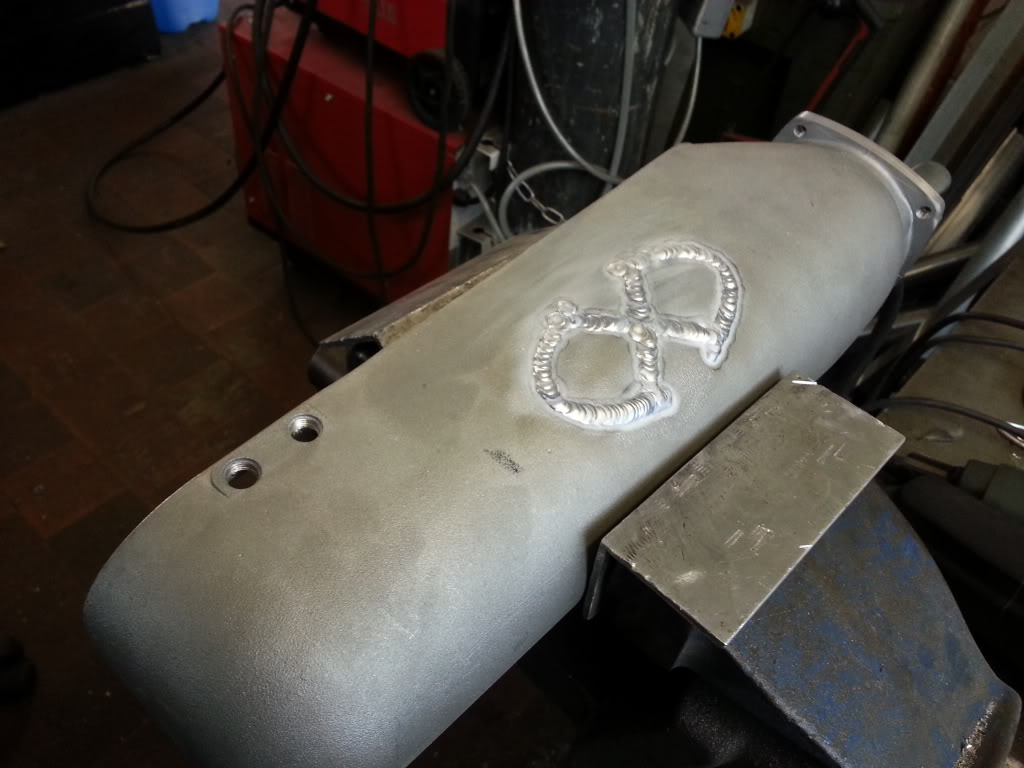

Based on that I tried a combo of the grey spring and brown spring (you can use up to 3 different sized springs in the Tial)... that should give 0.9bar at 1:1 but was hoping it would be 1bar with the variance but... the grey spring is quite tall and basically due to the space limitation and a little help from the next door neighbour there was no way I could hold it compressed enough for long enough to get the bolts in

So I used a maroon spring with the brown spring and managed to get the thing held down long enough to get the bolts in! phew!!! put the engine bay back together and of course... what external wastegate and large turbo???

Took the car for a quick test drive on 'actuator' pressure only (unplugged the N75) and bingo... 1bar on the gauge... result... I also changed the spring in my super size DV from the white to the red... I was never happy that the spring had enough preload when the valve was assembled so I plonked in a couple of shims to add a bit which helps keep it shut however I did notice that when changing gear under WOT at high rpm I was getting a hint of compressor stall so rather than risk turbo damage (did sound cool though) and to keep the valve closed I swapped out to the red spring which is a little softer... no more flutter on gear changes now and 1bar boost to redline...

A Good evenings work but does mean I need to go back to the map and look at my boost maps as I suspect thats going to change a bit now so until I have dropped it down a bit I won't be running with the N75 connected just yet...

<tuffty/>

lol as he did to me but i seriously couldn't get it right