Borne out of this issue was the need to repair my engine. I decided i was going to rebore the block and fit new pistons. While i was sorting the spec required Bill @ Badger 5 happened across an ABF crank from a 1.8 16V Golf. This happens to be the exact crank needed to fit into an 058 block to build a stroker engine.

I made the decision to stay with a sensible bore size and went for 82.5mm, this proved to be a limiting factor as there are not many brands still available in this size, they all are 83mm. Also the added bonus of staying 82.5mm is that the OEM gasket can still be fitted.

OEM v Woosner stroker pistons

Note the reduced deck height

Deck height differences

This is with the pins lined up to show "fitted" position as it were. Also noteworthy is the additional clearance for the oil squirter's. I know 4th is the closest one normally, but this seems on a dummy run to allow that clearance for the 4th squirter as fitted

Brute rod and stroker piston side by side

The astute amoung you my notice the engine has made it into the house ;-P

It was cold in the garage,LOL

It was also easier to start measuring stuff

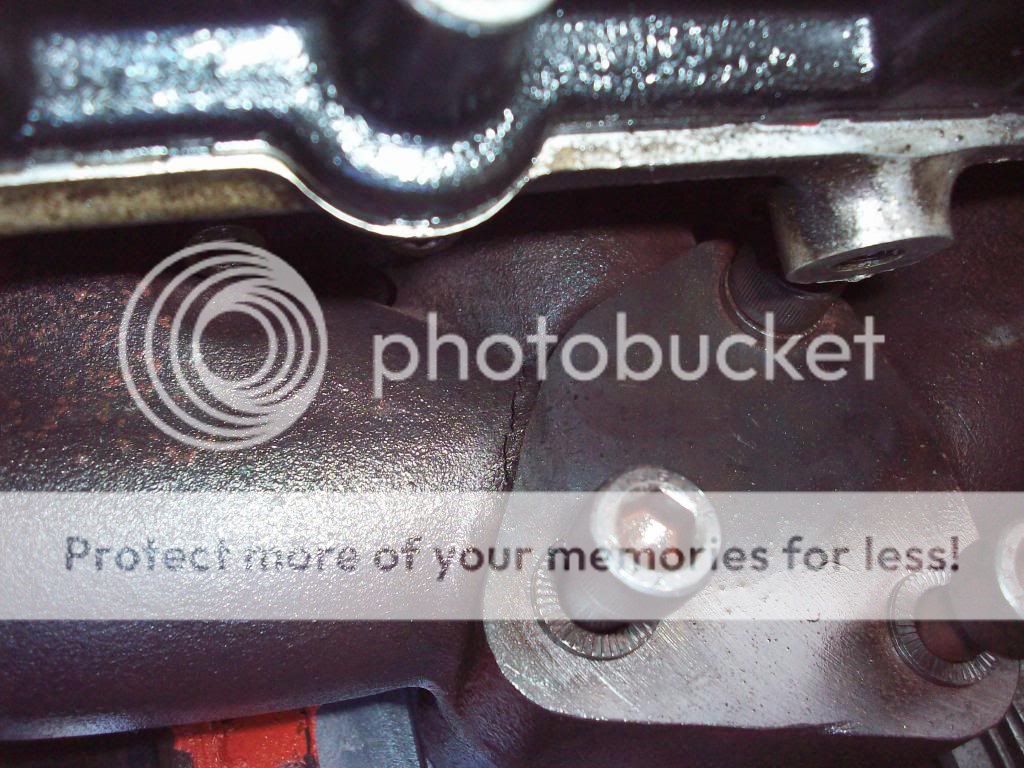

This is a lump near the bottom

This issue is a gallery style casting further up the block

This seems to be one of the 2 contact point so far.

A few of the others are close, but not measured yet as my feelers are rusted( lack of use) so i need to acquire some more tomorrow

My rods don't seem to be close to the bottom skirts of the bores like Andy's above. It must be due to the brand and style of rod v bore v stroke v piston choice maybe?

My IM shaft was reduced by 5mm from the inside out as per spec to allow clearance