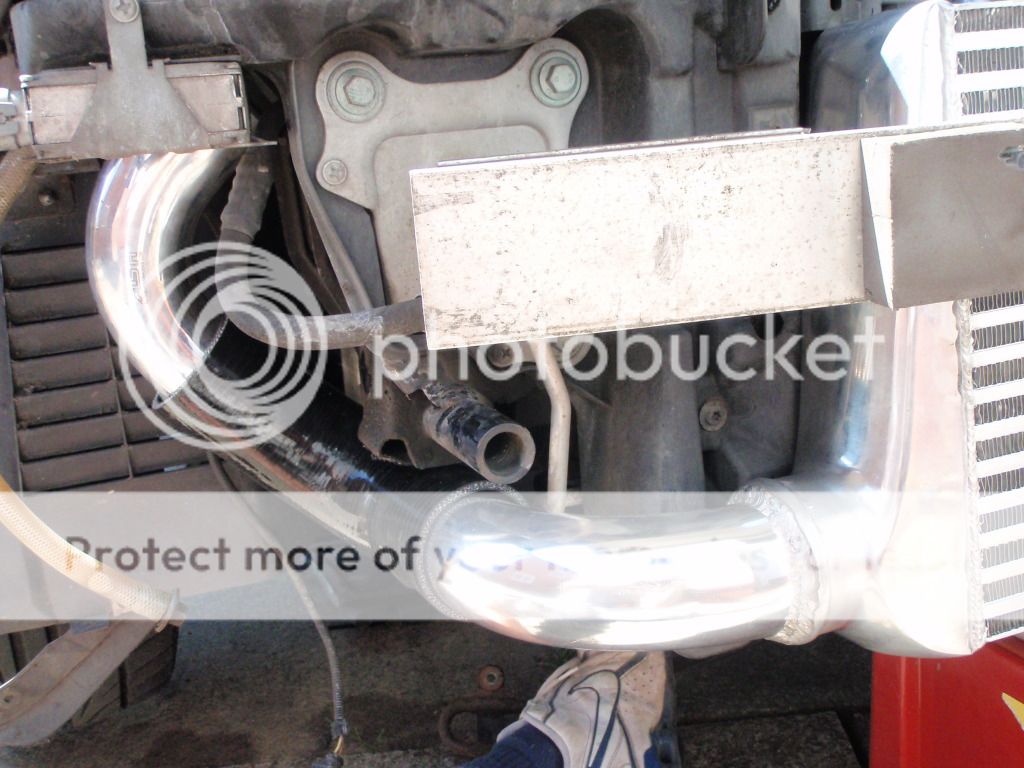

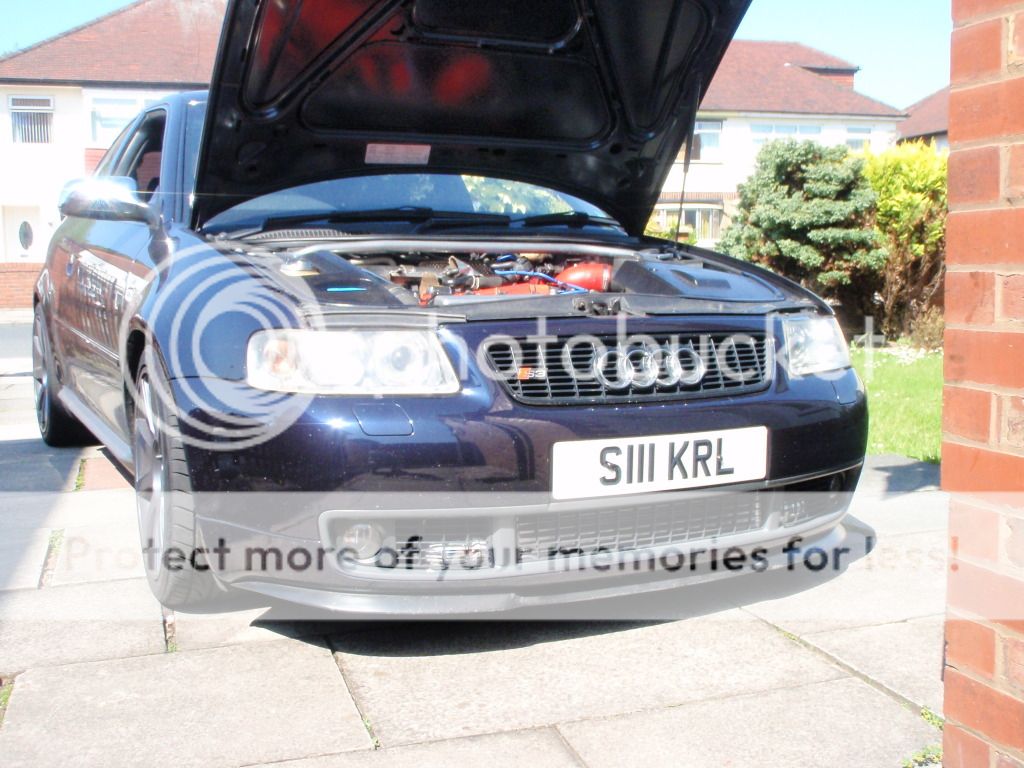

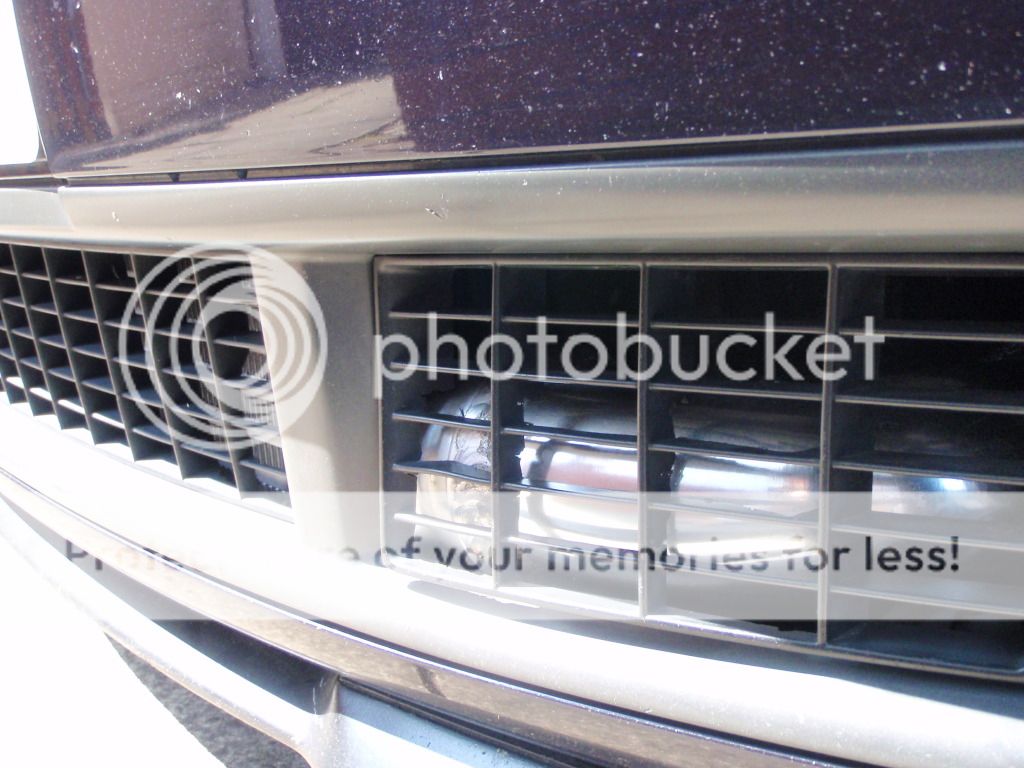

Hi all, where can I buy (online) the correct alloy and silicon bends and clips for fitting the AH Fabs V2 ?

And do I order 60mm or 63mm tubing ? Because original is 60mm I guess and the FAB V2 has 63mm bends ?

63mm as I told you in the PM you sent me at 9am this morning mate...

Steven, ALL the information you need is in this thread, all the links to sellers, the sellers everyone has used, the lists of parts they have used, many people, Bill, Welly, Westy, Tufty, Karl, Sportstractor, myself, and many others have all taken the time to post up detailled write ups with links, pics, problems, solutions, everything. Please take time to read all 12 pages before posting any more FMIC questions.

There can be nothing more frustrating than being PM'd a question, and giving a full and thorough answer, only to find that exact question posted on the public board a few hours later. The original recipient of your PM has obviosuly been selected for a reason, so you've already in effect 'validated' the quality of the response before you've even pressed send!

If you're going to do something like that, you're best just asking in here first, that way people don't feel like they're wasting their time going to the trouble of writing a detailled PM direct to you, only for it to be ignored.