Hybrid turbocharger k04 build

- Thread starter beachbuggy

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

beachbuggy

Registered User

wouldnt an mbc in parallel with the N75 solve this problem?

Yes, but really with a stock k04 I don't think it is needed, I have an MBC as a safety backup but I don't think a stage 1/2 should really be boosting upto 25psi anyway.

beachbuggy

Registered User

are you talking about the turbine housing?How much is machined out? Do they do it on a normal lathe with a boring bar etc? And where exactly from on the turbo?

@ Rich196, 1.7bar on a stage one is just not right! I'll take it back as at those boost levels all you're doing is pushing loads of hot air and that just isn't going to last long(turbo or even rods) Was your car mapped on a rolling road?

Who mapped it? I'd suggest if it's overboosting it's a mapping issue.

Road mapped by a well know tuner, not many road map so you can guess who. The over boost is really tiny.

You would get a better response with a yellow spring..

25 psi seems high for 215 g/s ?

What were the results on the dyno?

I wont mention rods...

Hasnt been dyno'd road mapped, but will be on rollers next month. I shall get a yellow spring. The car was flowing well apparently so the boost could be turned up a bit.

When you say over boost, is it climbing to 25psi. Fluttering and then settling at say 21psi tapering down? I only ask as I've been experimenting with my hybrid as I was getting the same thing but climbing to 27psi then settling at 23psi. I've been playing with the PID maps specifically the D by increasing it, which in essence makes larger compensations for over shoots on the n75 to get it back to we're it should be to controll the n75 and ultimately the actuator. Having done this it's significantly reduced the overshoot and flutter, my point being I'm convinced the n75 is just not reacting quick enough and hence the over shoot, I'd be inclined to side with prawn and say its a mapping issue. Surely 1.7bar is high for a stage 1 stock k04 remap anyway?

Map is stage 2, over boost is tiny. doesn't even last a second! We tried 27psi to start with but it over boost for so long it wasnt good for it. So it came back to 25 psi with tiny over boost, then drops back and holds around 22 all the way through the rev range.

@ Rich196, 1.7bar on a stage one is just not right! I'll take it back as at those boost levels all you're doing is pushing loads of hot air and that just isn't going to last long(turbo or even rods) Was your car mapped on a rolling road?

Intake temperatures dont get that hight to be honest. I havent got the logs to hand but I dont think we were seeing much about 45. I dont rag it for long periods of time.

I am 100% confident in the map and who did it. I was explain the risk of running higher boost and that its a case of seeing how well the turbo lasts, and I was happy with that. This really was just a question to find out what hardware changes would best over come my marginal overboost.

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

factory cars overboost....... to put it into prespective.. they overshoot their programmed boost..

beachbuggy

Registered User

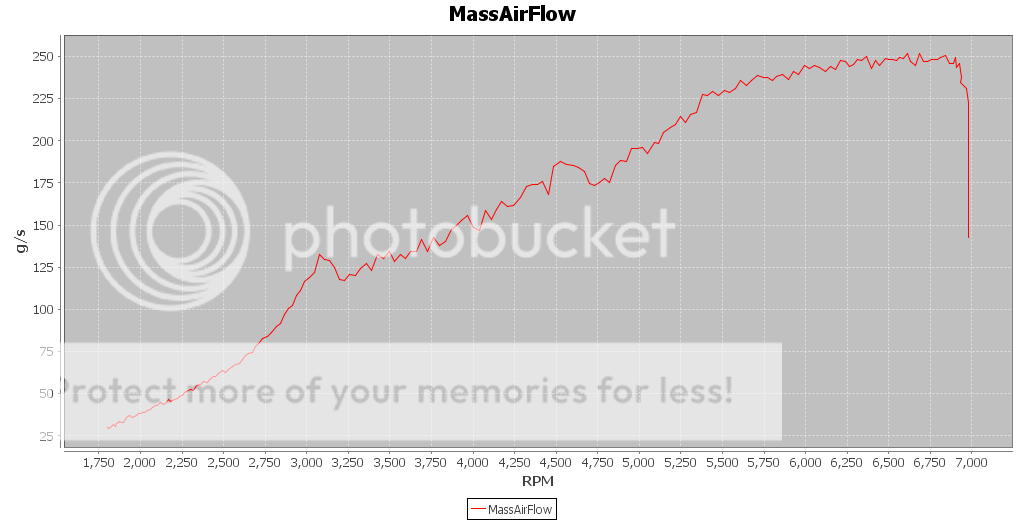

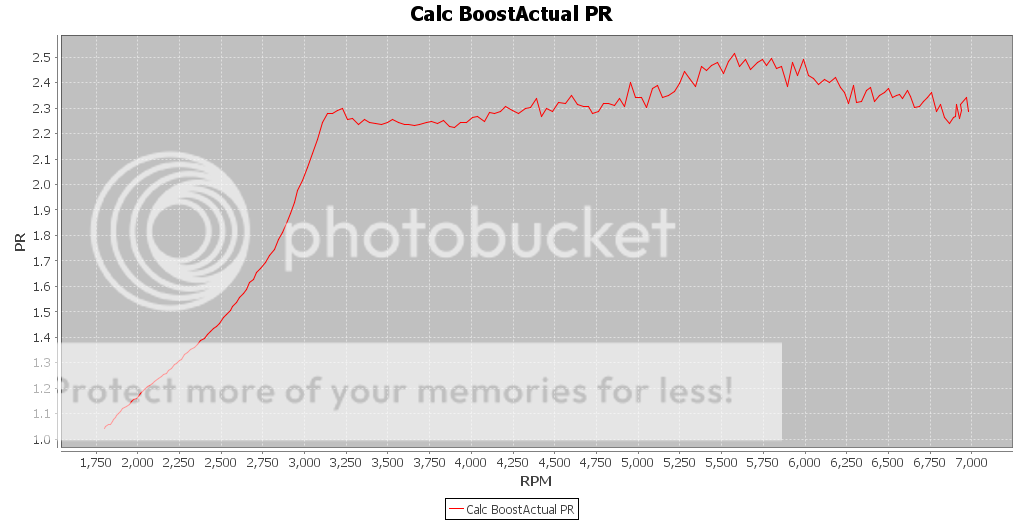

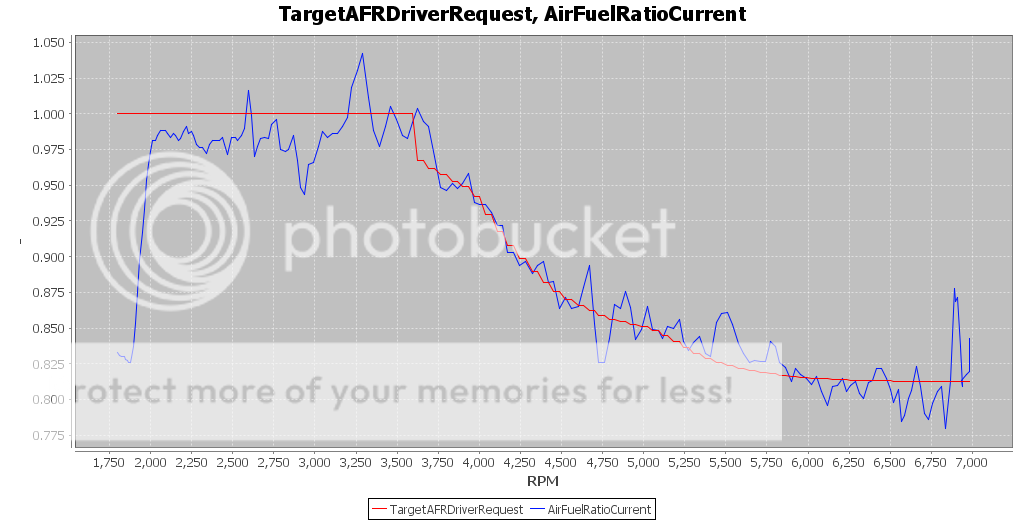

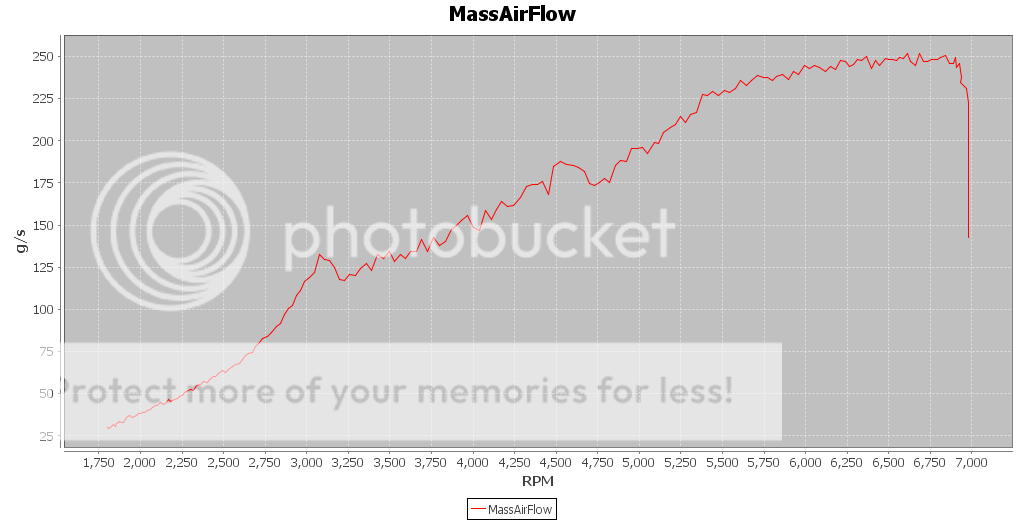

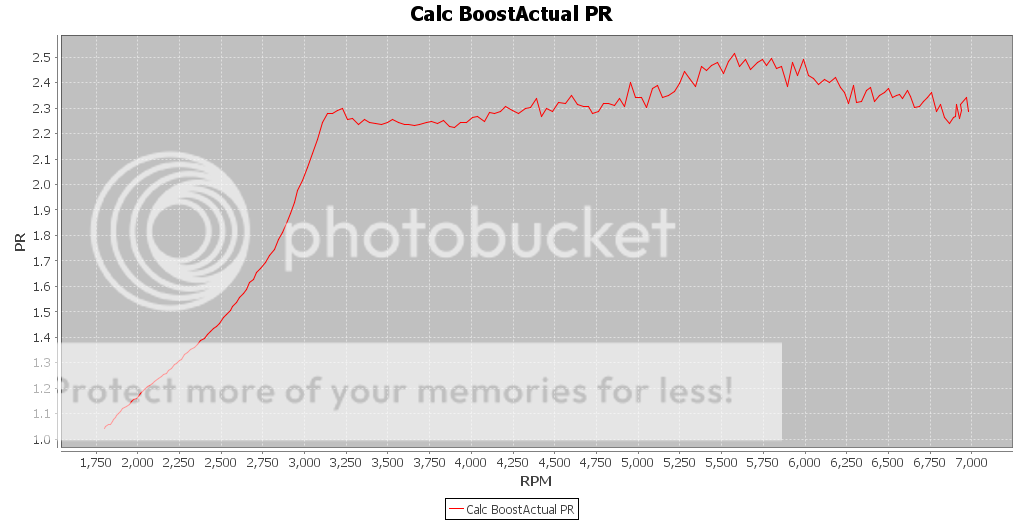

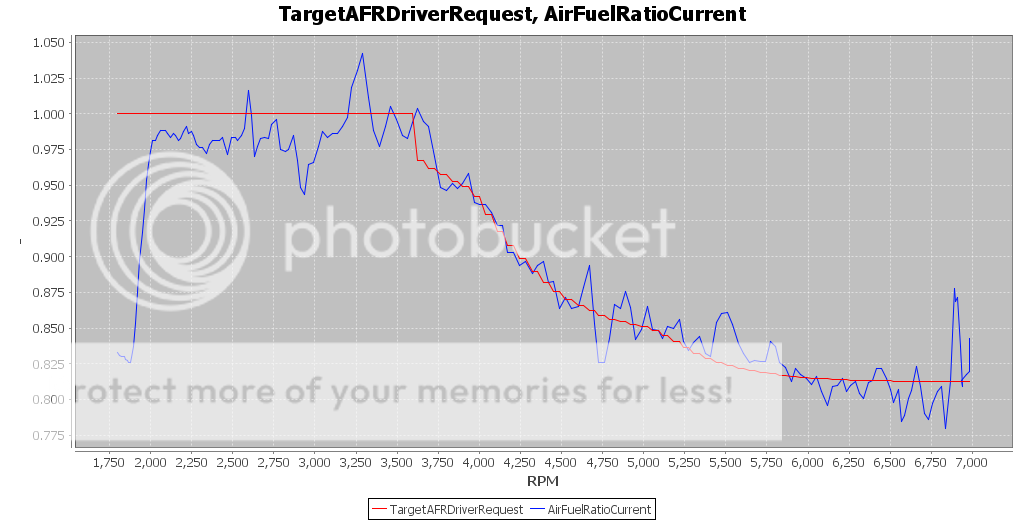

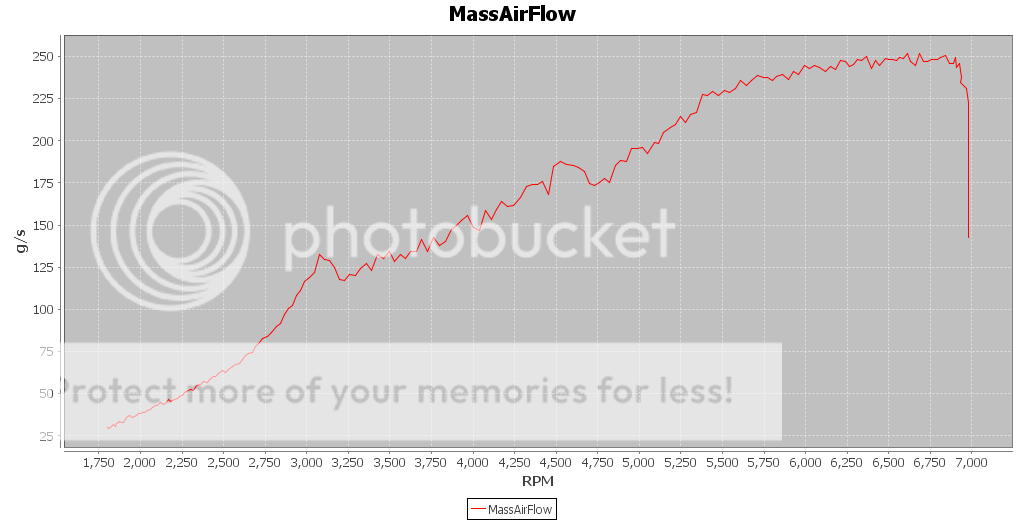

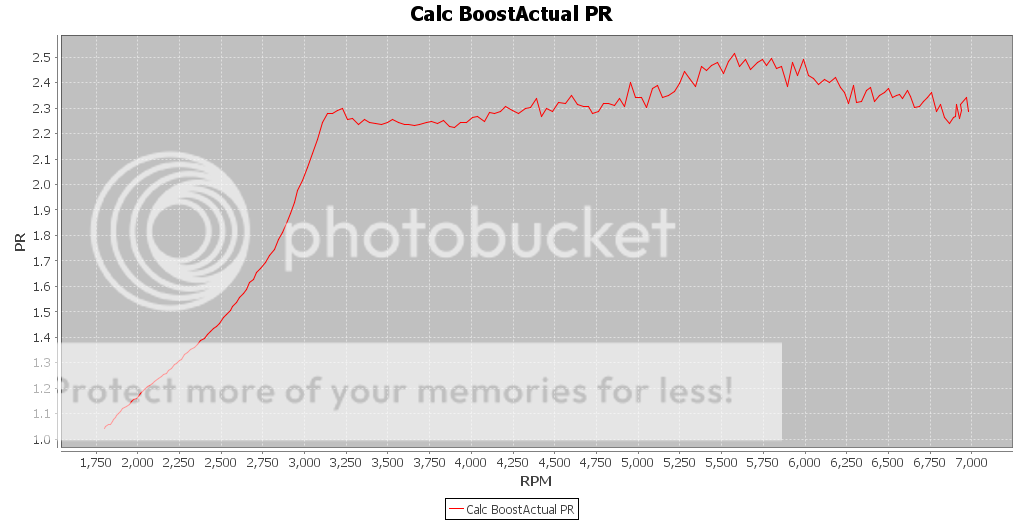

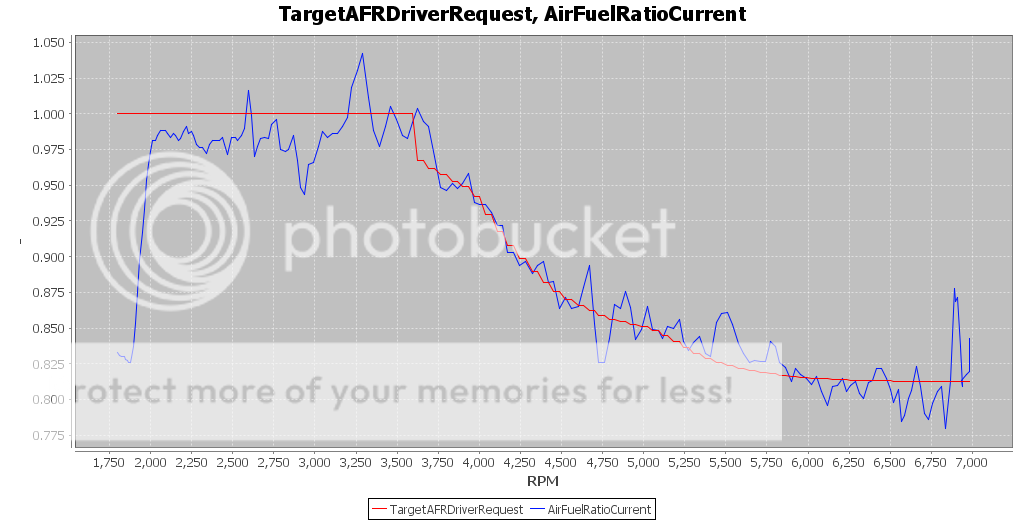

So after a few hickups, leaking gaskets and clutchs going I have finally got a tune I'm happy with.

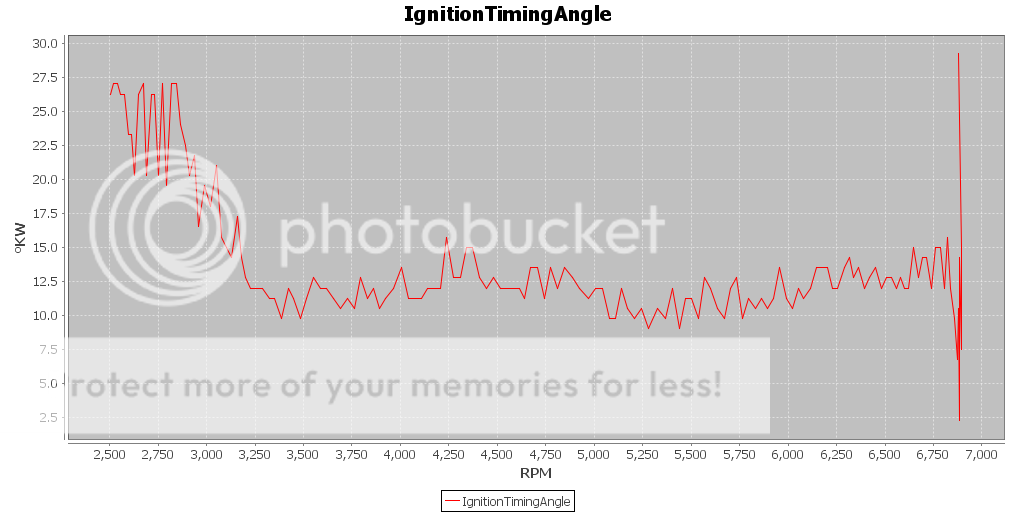

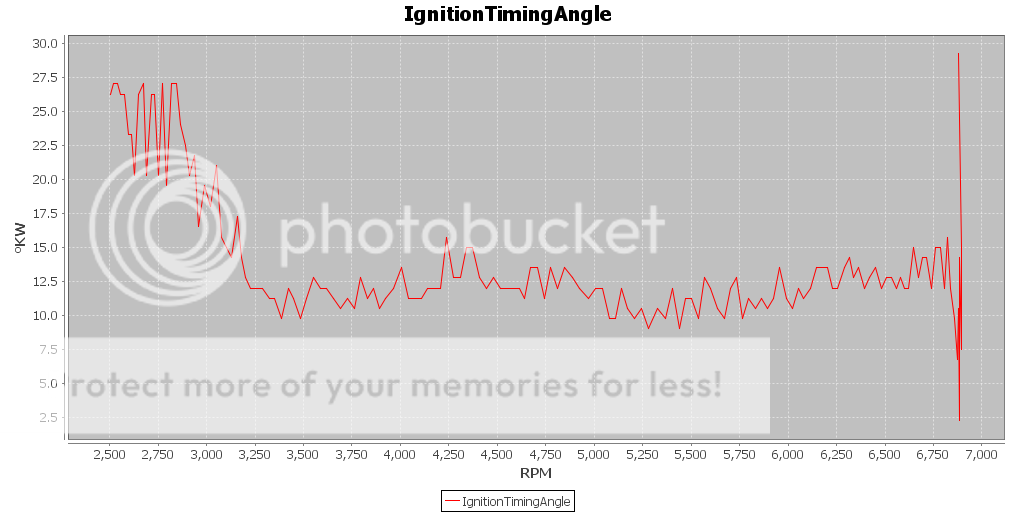

The following graphs are logging using ME7logger and the map was tuned by myself having spent the last year learning the ins and outs of the ME7 ecu.

I've been running the car at a sensible boost inbetween tweaking the maps and understanding what the different maps do, there is definately more to give with the engine. More importantly the hybrid turbo is giving good results which I knew anyway but it's good to see it in black and white.

Spec wise the car is a hybrid k04, xs power manifold, blue flame dp and cat, B5 tip, 550 injectors, Ie rods, Small port head. ME7 BAM ecu upgrade.

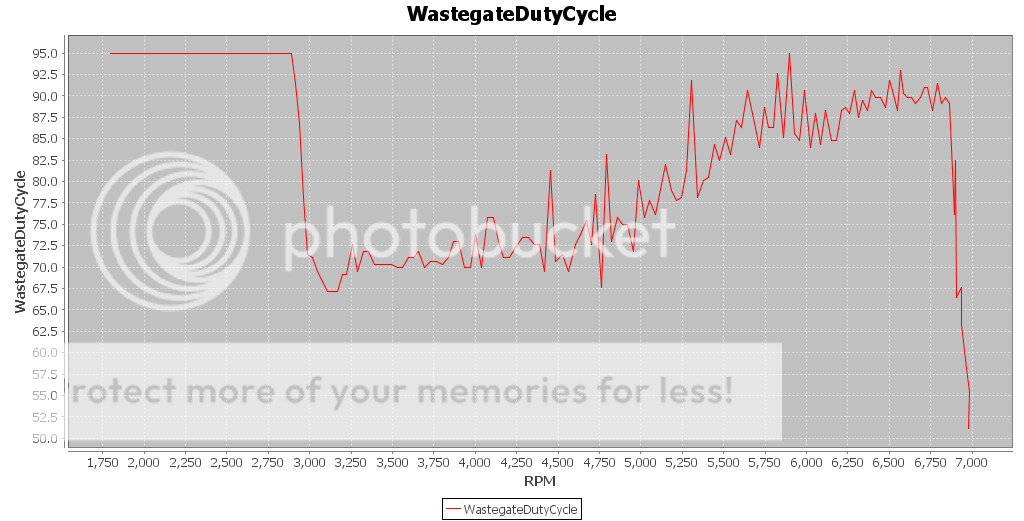

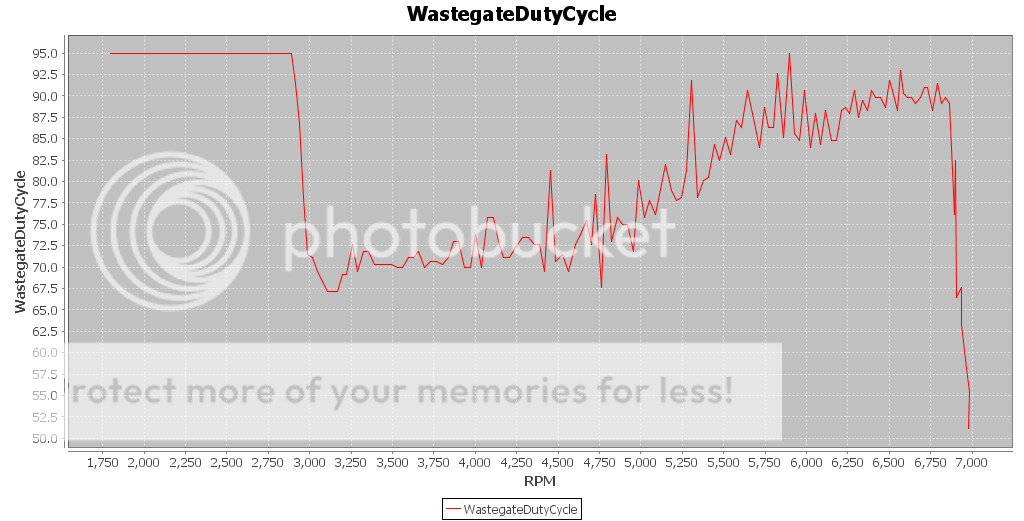

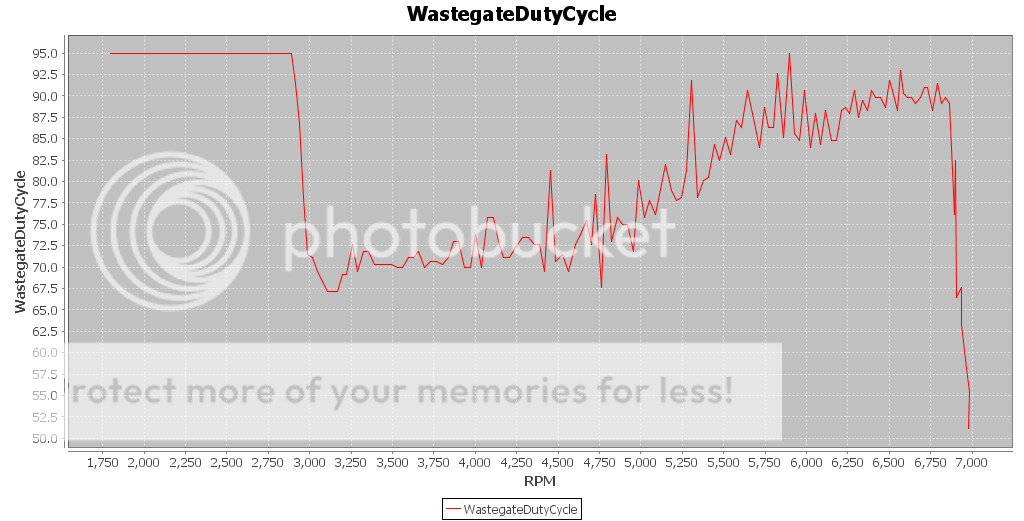

As you can see I have either a boost leak or the N75 maps can be tweaked to make actual meet requested.

Please also bare in mind this logger is far more accurate than VCDS and has a far higher sample rate hence the up/down lines as it's logging the m/s values.

The following graphs are logging using ME7logger and the map was tuned by myself having spent the last year learning the ins and outs of the ME7 ecu.

I've been running the car at a sensible boost inbetween tweaking the maps and understanding what the different maps do, there is definately more to give with the engine. More importantly the hybrid turbo is giving good results which I knew anyway but it's good to see it in black and white.

Spec wise the car is a hybrid k04, xs power manifold, blue flame dp and cat, B5 tip, 550 injectors, Ie rods, Small port head. ME7 BAM ecu upgrade.

As you can see I have either a boost leak or the N75 maps can be tweaked to make actual meet requested.

Please also bare in mind this logger is far more accurate than VCDS and has a far higher sample rate hence the up/down lines as it's logging the m/s values.

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

- Joined

- Nov 11, 2009

- Messages

- 10,099

- Reaction score

- 739

- Points

- 38

- Location

- west yorks

- Website

- www.stainless-engineering.co.uk

beachbuggy

Registered User

obviously taking maf/.8 it would be around 315bhp yes.. And no surge running at about 19psi. I'm sure if I can get actual boost up with requested I'll hopefully be at 320bhp . I have a strange issue i'm looking into as me load seems to be pegged at 191.7 which I think is also holding it back as I'm requesting 200-210 which it should easily meet. I'm also sure I don't have a boost leak. And looking at the n75 duty cycle think that they can be improved to sort this out. I'll have a play tomorrow to find outSo is that hybrid making around 315bhp? And thats not even with a largeport head or ragging the nuts out of the hybrid?

beachbuggy

Registered User

So with a largeport head and more map playing whats the most you think the hybrid of yours would achieve?

Honestly, I don't know. Wellys was running 344bhp. Without looking I don't know what psi that was at and this is the same spec turbo all be it I've modified the turbine housing , which I'm not sure if it increase power but it has saved me from running a clipped turbine wheel. I've also found its not about how much boost but how you deliver it especially with this turbo design. Going to hold off giving a bhp figure but I can say I'm more than happy with 315bhp so far with the premise of more to come.

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

And althougglh it may suggest 315 from airflow this mifht not transfer to the dyno.

My car suggwsts 238 and i very much doubt it would produce that with my oem map.

19psi is very low for a hybrid is-t it? So theres quite a bit to come in boost alone surely.

My car suggwsts 238 and i very much doubt it would produce that with my oem map.

19psi is very low for a hybrid is-t it? So theres quite a bit to come in boost alone surely.

obviously taking maf/.8 it would be around 315bhp yes.. And no surge running at about 19psi. I'm sure if I can get actual boost up with requested I'll hopefully be at 320bhp . I have a strange issue i'm looking into as me load seems to be pegged at 191.7 which I think is also holding it back as I'm requesting 200-210 which it should easily meet. I'm also sure I don't have a boost leak. And looking at the n75 duty cycle think that they can be improved to sort this out. I'll have a play tomorrow to find out

Load isn't pegged at 191, it's just that for logging purposes it is stored as an 8 bit number where FF=191.

Rick

beachbuggy

Registered User

Load isn't pegged at 191, it's just that for logging purposes it is stored as an 8 bit number where FF=191.

Rick

Is that with VCDS only? I am currently using ME7logger which I was led to believe would show the load in full however it seems I might have been logging the wrong thing anyway as Nyet on Nef has suggested I try rl_w rather than rl which I assume may show the full value unless like you say the 8bit ff=191 is maxed anyway.

Hopefully though is I can get the duty cycles sorted and the Actual to meet the requested I should be luck.

woking rob

Registered User

i need to pull my finger out and get mine fitted so i can give u some more feed back but this is a good wright up, top work :thumbsup:

Beachbuggy thats really awesome work. i was searching the net for how to disassemble a K03s turbo and came across this and learnt so much more. i was looking to rebuild the K03s myself to standard spec to learn and not pay rediculous fee's. but you have got me thinking now.

so the compressor housing is not big enough to take machining for a larger wheel, but the the exhaust turbine can be upsized? is that right? im from camberley!

so the compressor housing is not big enough to take machining for a larger wheel, but the the exhaust turbine can be upsized? is that right? im from camberley!

beachbuggy

Registered User

Beachbuggy thats really awesome work. i was searching the net for how to disassemble a K03s turbo and came across this and learnt so much more. i was looking to rebuild the K03s myself to standard spec to learn and not pay rediculous fee's. but you have got me thinking now.

so the compressor housing is not big enough to take machining for a larger wheel, but the the exhaust turbine can be upsized? is that right? im from camberley!

K03s compressor will take the k04 comp wheel but it leaves the inlet for the turbo soooo thin it's scary and I wouldn't want to use it, even putting the tip on and doing up the jubilee clip would distort it and run the risk of damage. It works out just as cost effective to buy a make a k04/k03s comp housing so you get the benefit of the k04 comp housing and the k03 outlet giving a stock looking turbo, this in turn allow a bigger comp wheel to be fitted.

Turbine housing comfortably takes the largest wheel available but it's then limited by its small size ( turbine housing)

if you need I can supply everything you would need to build what you wanted.

so its best to leave the compressor side and increase the exhaust turbine on the K03s?

i think i need a new chra as the in-out play was alot.

took it apart and its pretty badly worn. the exhaust turbine wheel has worn down on the heat sheild cap, the compressor wheel has worn down on the compressor housing. the cover that i cannot get off is worn a bit also i think where the bearing has ground in from the in-out play. the shaft is ok, it didnt have up or down play.

i just need to get the compressor cover of the compressor housing to get the compressor wheel out. then i can assess.

this is sealed in isnt it?, so should i refit it all then tap the compressor housing off?

i think i need a new chra as the in-out play was alot.

took it apart and its pretty badly worn. the exhaust turbine wheel has worn down on the heat sheild cap, the compressor wheel has worn down on the compressor housing. the cover that i cannot get off is worn a bit also i think where the bearing has ground in from the in-out play. the shaft is ok, it didnt have up or down play.

i just need to get the compressor cover of the compressor housing to get the compressor wheel out. then i can assess.

this is sealed in isnt it?, so should i refit it all then tap the compressor housing off?

thats a yes to tapping it apart.

whats the verdict? i think the back plate from the compressor housing is damaged as the area where the bearing contacts is worn/grooved as is the bearing part which is against it.

whats the verdict? i think the back plate from the compressor housing is damaged as the area where the bearing contacts is worn/grooved as is the bearing part which is against it.

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

beachbuggy

Registered User

but repairable?

Put it this way , the only thing worth keeping is the turbine housing assuming its not badly cracked and the compressor housing but it's scored. It's needs new chra as all of that is now not worth using

all stripped down, parts with screwdrivers pointing at them are worn. also need turbine/shaft and compressor backplate.

how does the rear oil seal on the shaft seal in the chra? mine is awol so cannot work it out. is it with the circlip which is still in the chra?

how does the rear oil seal on the shaft seal in the chra? mine is awol so cannot work it out. is it with the circlip which is still in the chra?

beachbuggy

Registered User

Holly cow! That is worn! Your rear seal probably snapped, it's a piston ring type seal that sits in a groove on the turbine and seals against the inside of the chra, that is only part of it as sealing is also done by back pressure in the turbine housing keeping the oil in.

slappy_dunbar

Let's Do This

- Joined

- Jan 2, 2010

- Messages

- 245

- Reaction score

- 20

- Points

- 18

- Location

- Westchester Cty, New York USA

- Website

- www.frankenturbo.com

Spec wise the car is a hybrid k04, xs power manifold, blue flame dp and cat, B5 tip, 550 injectors, Ie rods, Small port head. ME7 BAM ecu upgrade.

As you can see I have either a boost leak or the N75 maps can be tweaked to make actual meet requested.

That logger is sensational! Very high resolution data. Based on what the logs show I wonder if you might have an EXHAUST leak rather than a boost leak. What are your O2 corrections showing? Also, 250-ish g/s is getting on the edge of the 550s' flow capacity at 3bar. If you've got a strong pump, up the fpr to 4bar.

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

Oddly, boost isnt meeting requested, but the waste gate duty cycle isnt anywhere near maxed out.

Looks like the Boost PID just needs some tuning?

Looks like the Boost PID just needs some tuning?

beachbuggy

Registered User

I don't think was the best example to be honest, I see your point though. This was actually done after I had tested the setup with a spring to assist the actuator which then held 23psi without issue, do to be honest I wasnt too concerned on the n75 map as I knew it wouldnt hold the boost so never put the n75 map back to stock. I'm pretty sure I had change the I and P to dampen down the overshoot, but decided an MBC was the safer option anyway which is where I am at now. I've just bought some 1 bar actuators to make up on stock brackets so hopefully that'll be fitted in the next week or so.

slappy_dunbar

Let's Do This

- Joined

- Jan 2, 2010

- Messages

- 245

- Reaction score

- 20

- Points

- 18

- Location

- Westchester Cty, New York USA

- Website

- www.frankenturbo.com

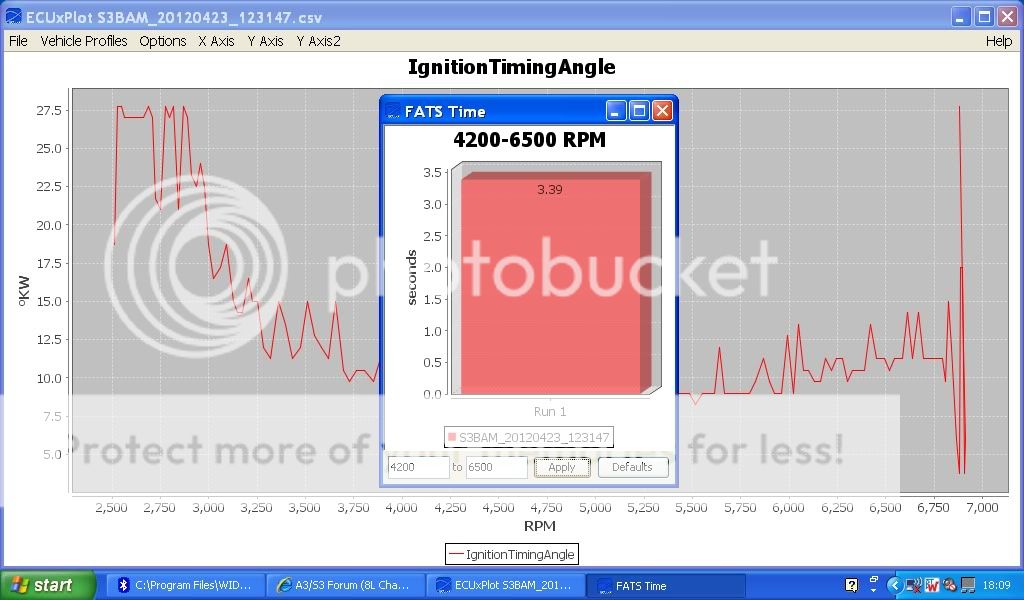

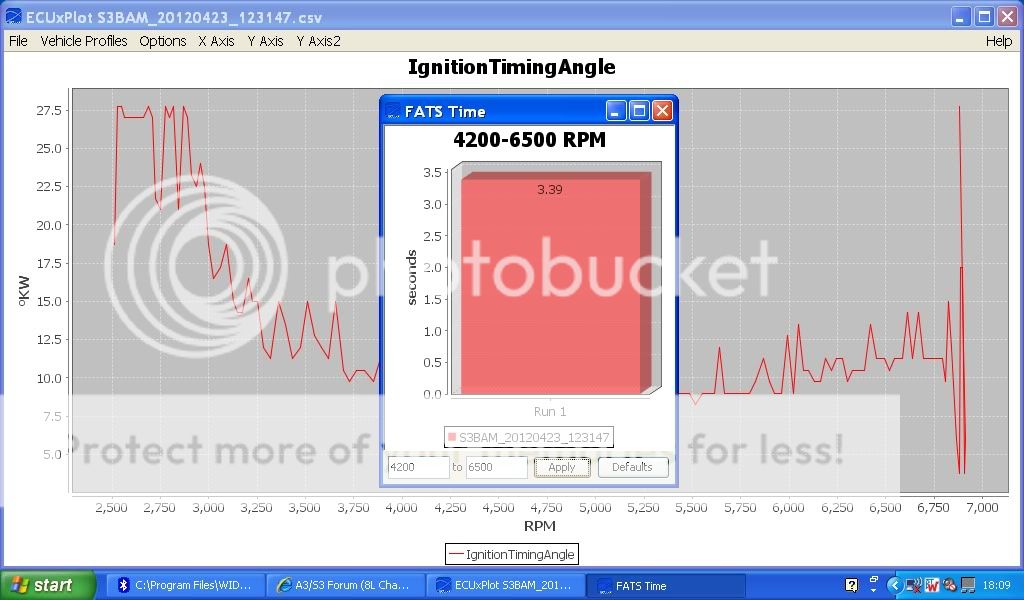

can you post your timing advance curve (in addition to the CF values already posted)? Also, this is an AWD 6spd manual, yes? If so, i'd love to compare FATs times with you. What's FATs? It's this:

beachbuggy

Registered User

Here we go, the logging software does fats as well so I have included a picture of that as well., I have no idea whats good or whats not.

Its an Audi S3 AWD 6 speed manual

Its an Audi S3 AWD 6 speed manual

- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

slappy_dunbar

Let's Do This

- Joined

- Jan 2, 2010

- Messages

- 245

- Reaction score

- 20

- Points

- 18

- Location

- Westchester Cty, New York USA

- Website

- www.frankenturbo.com

Here we go, the logging software does fats as well so I have included a picture of that as well., I have no idea whats good or whats not.

Its an Audi S3 AWD 6 speed manual

3.39 seconds (in 3rd I presume) is already good. That's about what I'm seeing as well now with the warmer weather. And I'm going to guess you are running straight pump gas -- no WMI. FATs is an excellent metric for improvements and modifications. I find it to be unflinchingly cruel about bringing me down to earth when I thought I've just had a good run. Despite the various disappointments, I'm still striving for a clean sub 3.00 in warmer temps.

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

how can we do a FAT's test Doug? Sounds interesting, and I'd love to see how mine compares to the S3 boys on the same / similar spec turbos

- Joined

- Dec 8, 2006

- Messages

- 12,100

- Reaction score

- 4,340

- Points

- 113

- Location

- Eastleigh

- Website

- twitter.com

Damn. I've just downloaded the same FATs calculator as you have above, and realised two things:

1. the only logs I've done on my hybrid were flat out through the gears logging IAT's, so my 3rd gear pulls following a second gear pull don't start until 4600rpm

2. my 5 speed is useless for a FATs comparison against you guys with a 6 speed so it's pointless. I was thinking 3s sounds VERY fast to get from 4200-6500 in 3rd for me, but i'll be doing another 20mph at the top end of 3rd!

so it's pointless. I was thinking 3s sounds VERY fast to get from 4200-6500 in 3rd for me, but i'll be doing another 20mph at the top end of 3rd!

Oh well, nice idea whilst it lasted. Could still be a handy reference for me for performance checking though

1. the only logs I've done on my hybrid were flat out through the gears logging IAT's, so my 3rd gear pulls following a second gear pull don't start until 4600rpm

2. my 5 speed is useless for a FATs comparison against you guys with a 6 speed

Oh well, nice idea whilst it lasted. Could still be a handy reference for me for performance checking though

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

overall gearing, which includes the gearbox, gear used, wheel/tyre size will all effect the times when comparing different cars...

slappy_dunbar

Let's Do This

- Joined

- Jan 2, 2010

- Messages

- 245

- Reaction score

- 20

- Points

- 18

- Location

- Westchester Cty, New York USA

- Website

- www.frankenturbo.com

overall gearing, which includes the gearbox, gear used, wheel/tyre size will all effect the times when comparing different cars...

Yeah. And that's very true when it comes to Prawn. But if you can safely do a run, I'd like to see it. And as I said, it's a solid means for assessment of progress during a build (plus it's quite a bit of fun).