So, enough buggering around, on to todays progress!

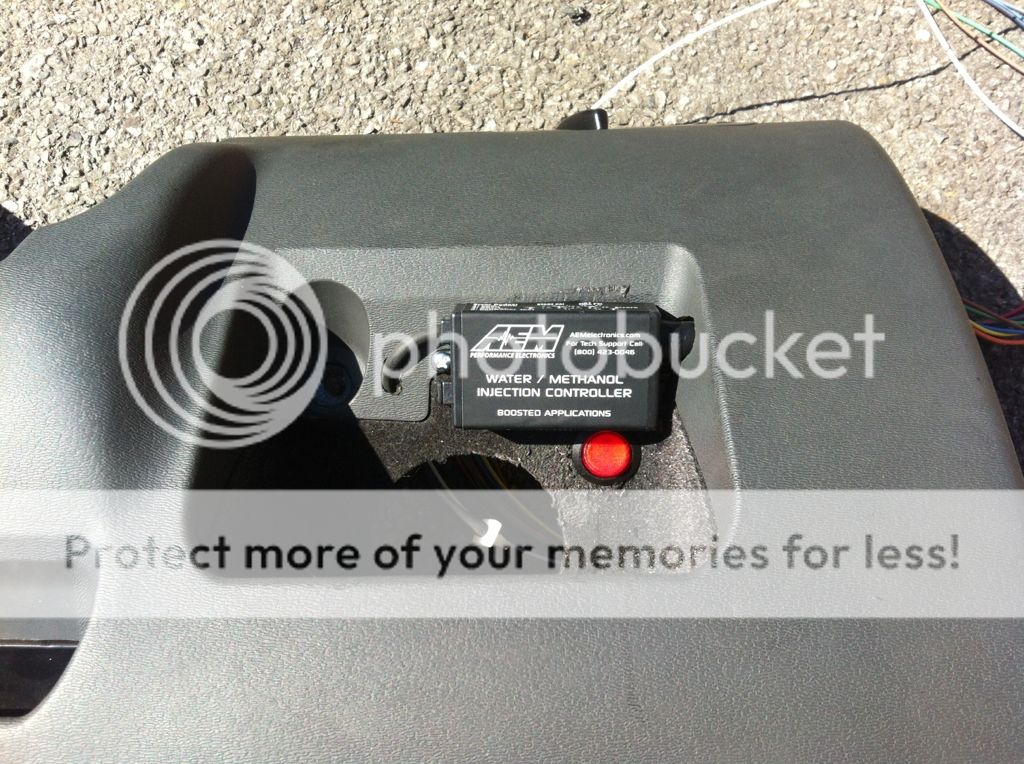

I started today with mounting the controller. Due to the way the wires come out the side of the controller, they'd usually be on display, but I didn't want this, as it'd look messy. So I set about making a cut out into the side of the cubby hole to hide the wires:

With that done and the wires fed through, I could slide the controller right over to the side and the wires went in through the hole I made, I also didn't want to just run the map sensor through the big round hole, as I was worried I might snag it when I frequently stock up the pocket with redbull cans!, so I made another hole and chamfered it in at an angle for the MAP pipe:

I also added a rocker switch into the 'ARM' circuit, so that I can turn the WMI system on and off depending on what I'm doing. I see no real need for it if I'm cruising down the motorway and want a few seconds of power to overtake someone. That would just be a waste of meth!

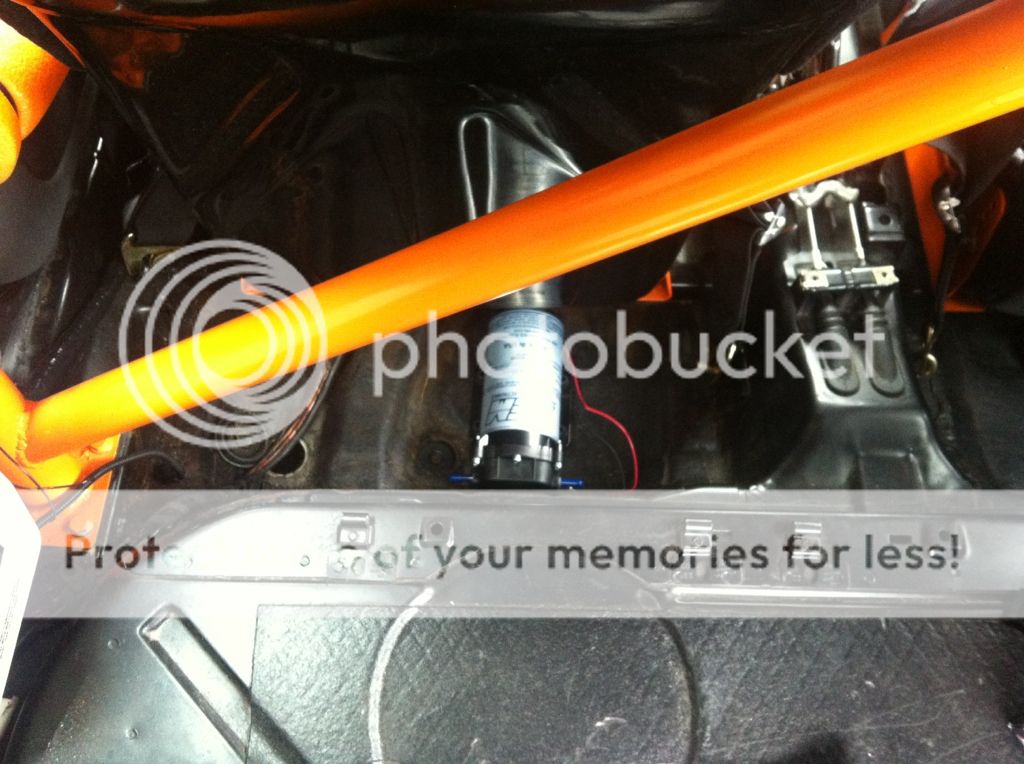

Then, seeing as I hate electrics so much, I thought I'd do a really simple task, and earth the pump:

Then after I'd done it, I realised that the pump didn't need earthing, as it's triggered by a short to ground on the controller. D'OH!

So, still avoiding electrics, I moved onto the FMIC pipes and WMI boss fitment.

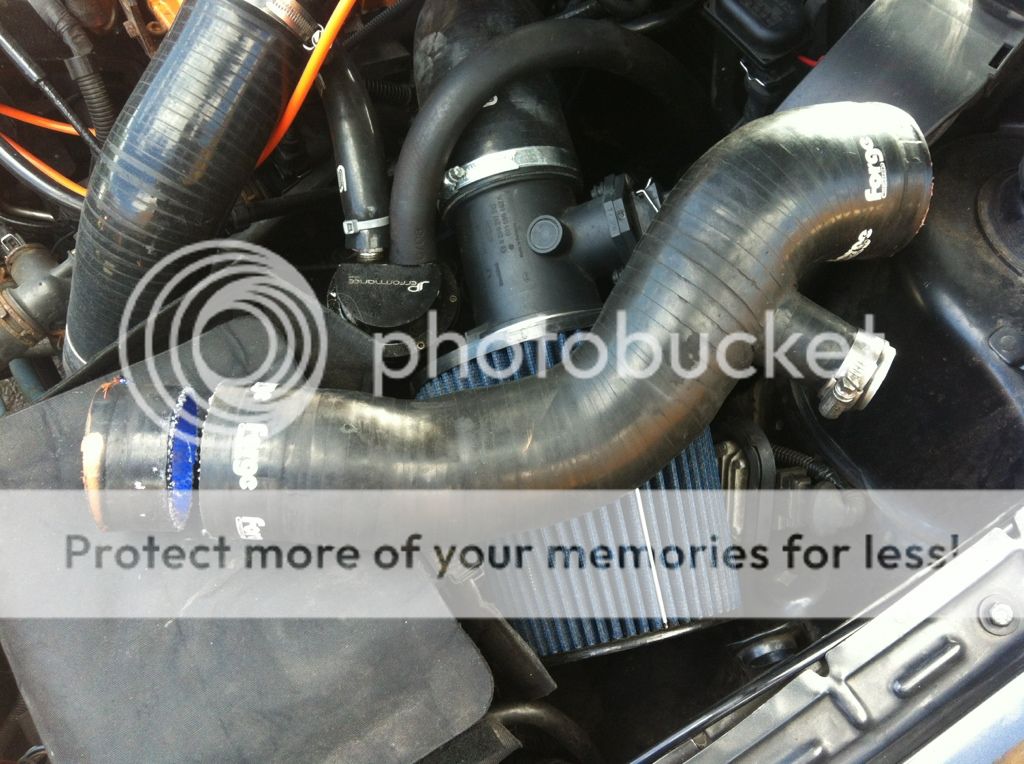

One WMI boss welded into a new pipe from Bill. Lovingly beaded by our very own Tufty whilst Bill prepared his race car for Combe on bank holiday Monday. Absolutely beautiful welding!

AEM small nozzle and check valve screwed on:

This was my old cold side charge pipe routing:

The new pipe from Bill was a tad longer than the old one, and the minor change of layout threw it all inboard at tad, so my throttle body hose needed trimming down 30mm:

With that done, it fitted perfectly, here's the new charge pipe layout, only 3 bits swapped around, and it's all still nice and neat:

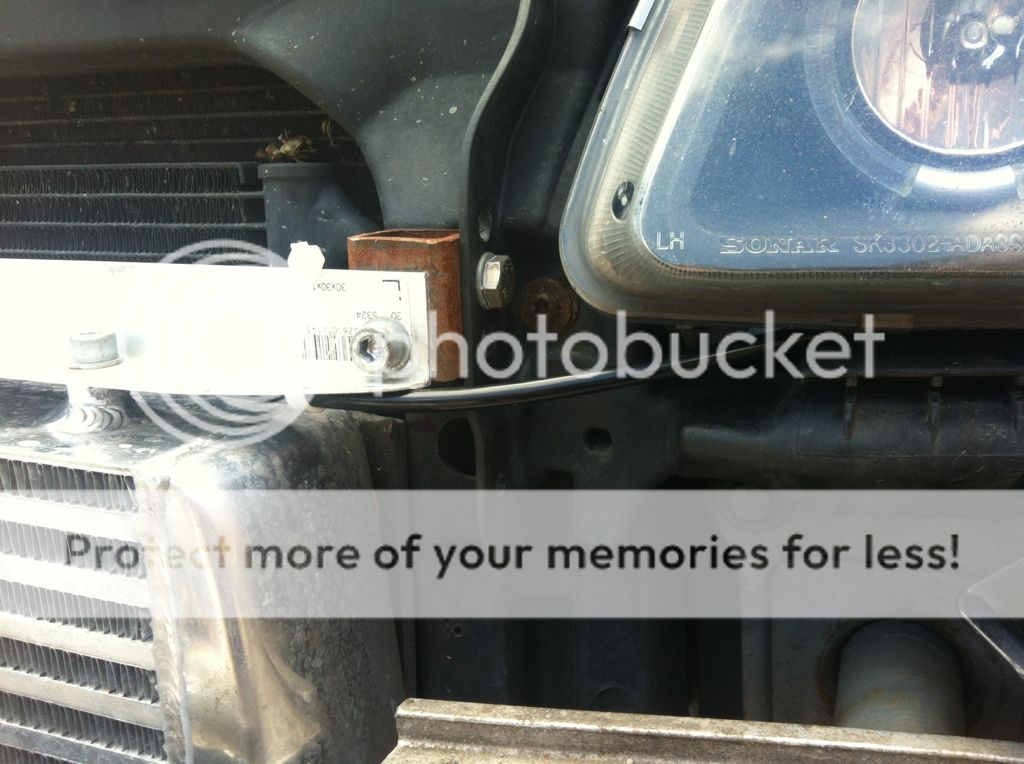

After searching for a place to bring the nylon hose through the bulkhead on the drivers side, I gave up, and went for the hole Dave told me about on the passengers side. I've now routed the hose from the pump, down the passengers side sill, through the bulkhead and down the pass. side wing, then across the top of the crash bar and down to the injector.

it pops out under the pass. headlight:

Then down to the injector on the other side:

Cracking job of avoiding the electrics side of it so far, but I'd run out of things to do before wiring it in, so I had to start!

Simple bit first, the earth on the controller, bolted with an eyelet onto one of the main earthing points under the dash:

Then the main power feed onto the pump, onto one of the main power lines in from the battery:

As the lower dash panel might be removed from time to time, I joined the two controller power feeds (controller power and LED) and put them on a spade connector. The last thing I want it everything tied together so I can't remove individual panels in the car:

The rest was simple, just follow instructions, join colours together. I was going to solder all the joints, but I've heard lately that people are moving away from soldered joints in motorsport due to the potential for them to crack and dry out, so instead I've crimped all the joints, and given them all a liberal coating of Petroleum jelly to aid conductivity

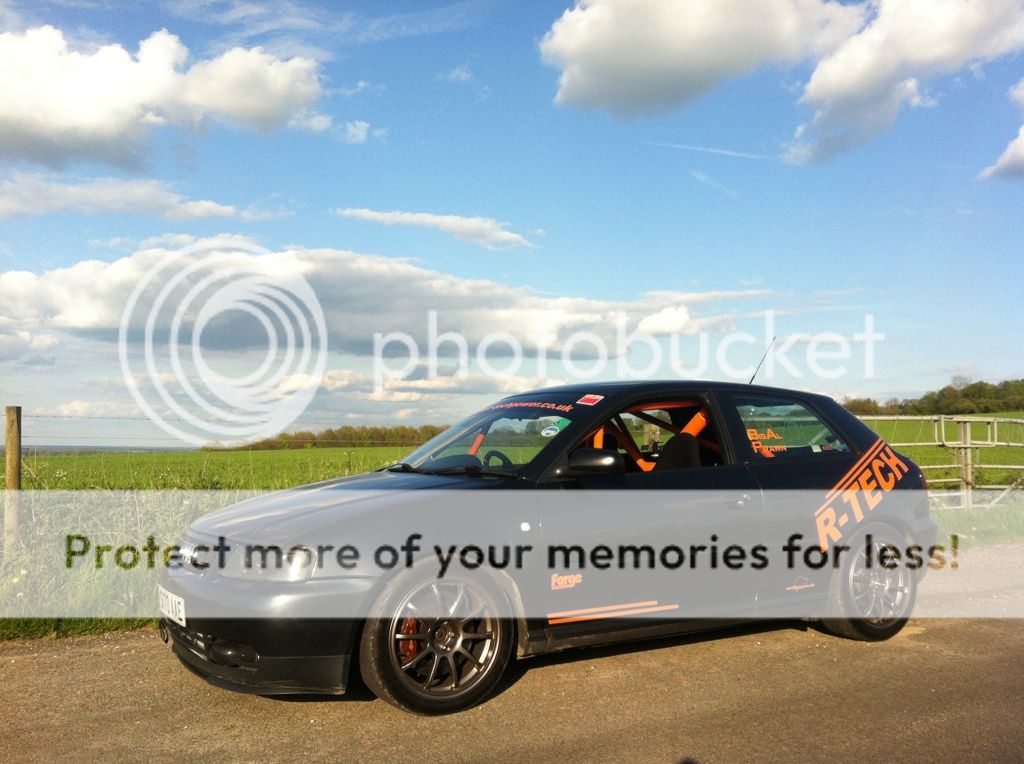

All back together:

^^^

^^^