Cheers Maz.

Right, todays progress, or annoying lack of due to near constant rain!!!!

Finally got the last of the evil nuts of doom removed, and by 10am, the manifold was off!

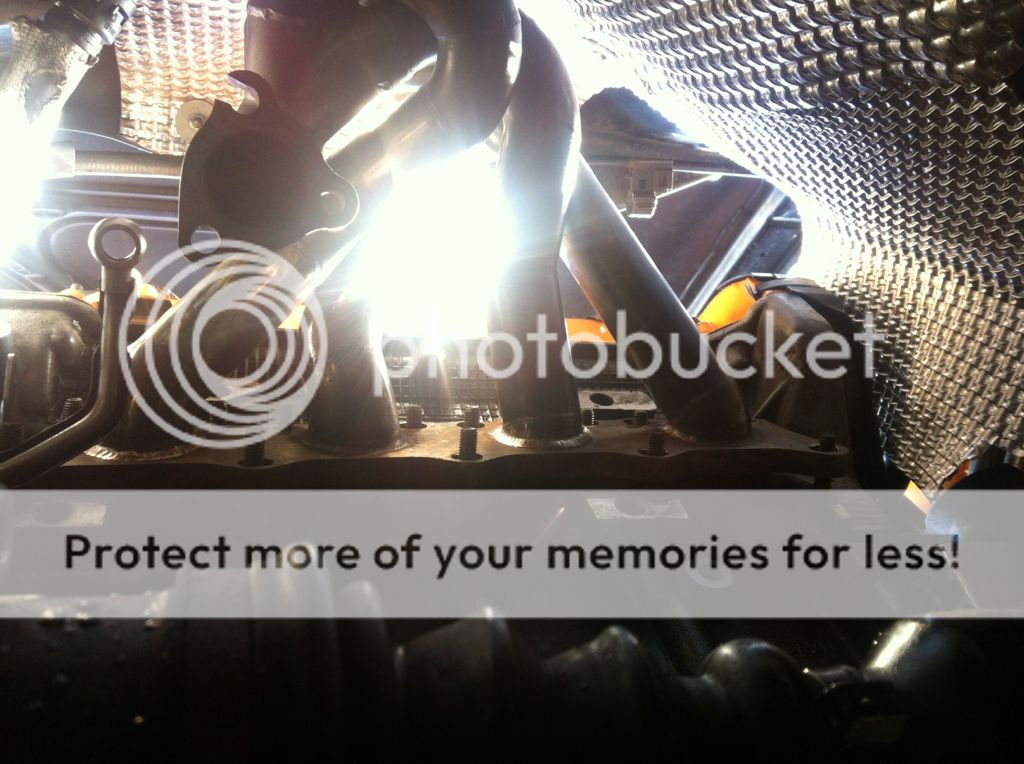

An issue that was mentioned to me when Rick built Sam Bryants engine, on the V2 manifolds one of the exhaust studs actually hits the runner on cyl 1, and stops if from tightening down properly:

Still not perfect then XS!

Simple solution though, just grind down the studs at the two tight locations. I whipped the studs out to do it properly, and ground them down and recut the threads, then wound them back in with thread lock, you can see the short ones in this pic:

Brand new nuts again, and of course the Nordlock washers

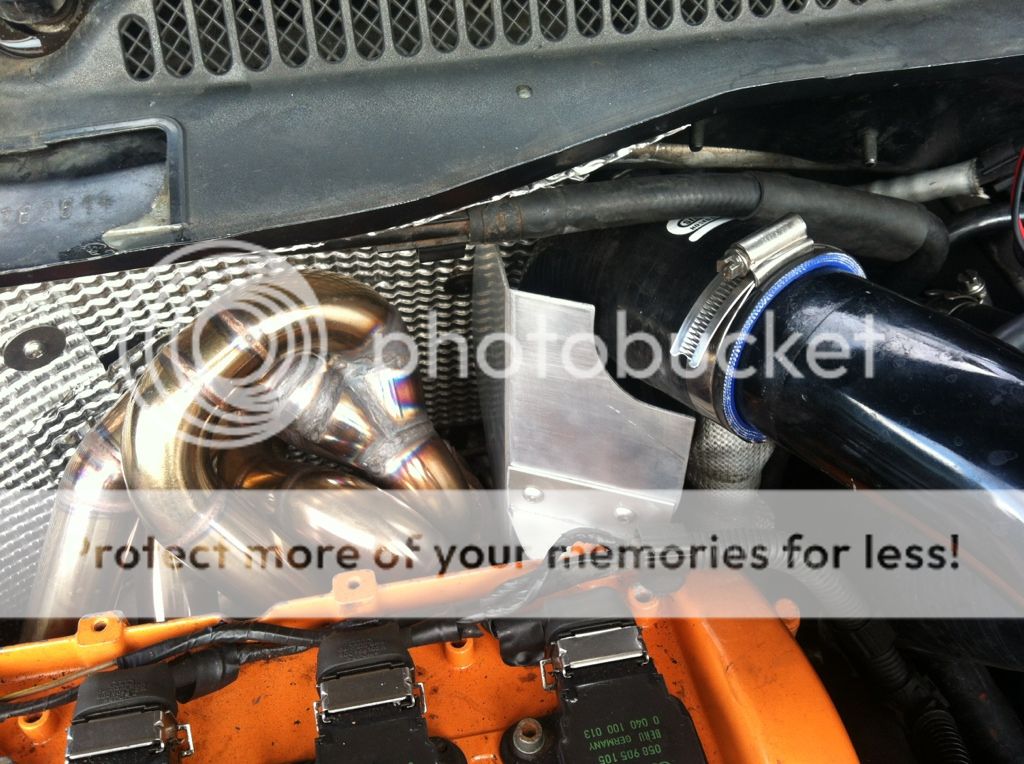

New gasket in place, and I bolted up my shiney new XSDave:

After I blew the hose at Rockingham, I bodged on a hose I borrowed from Andy, not the right size, but it worked. This hose has been on the car for just 200 road miles, and I think one track session on actuator pressure.

You can see how the heat was already effecting it here:

Give it a squeeze and it gets a whole load worse!

New hose ordered from Mr Silicone, known as AP motor store on ebay, arrive yesterday:

Nothing unusual there.....

However:

It's quite clearly a hose from siliconhoses.com (sister company to Forge), sent to me by Mr. Silicone. Most bizzare!

Everything back in and slotting together nicely, and it's alive!:

About 5-10mm more room behind the V2 manifold compared to my V1 before:

Time for some more CAD to get this heat shield under way:

30 mins later after plenty of filing and triming, I came up with this rubbish looking bit of plate!

All will become clear when it's in place, it actually looks quite smart, but it's raining again, so it can wait!

Manifold already turning several shades of gold after just 5 minutes running

Maybe more later, maybe tomorrow, depends if the F1 gets dull or not in the next 45 minutes