Right folks, as per tuftys request, Iâm copying this over from a PM I sent to a few chaps today.

This is my version of the Welly cooler, for the A3. This arrangement is for a ko3 framed turbo, and should work with minimal/zero trimming of the pipes/silicon. Ko4 fitment is slightly different, replacing the turbo outlet pipe with a 54-63mm silicon reducer.

This is the core, as owned by many on here already:

eBay - The UK's Online Marketplace

itâs a beast, and itâs SUCH good value itâs unreal.

To fit that, youâll need to cut the back of the crash bar out, but thatâs dead easy and takes 5 minutes with a grinder.

As for mounting height, I opted to hang mine with around 6ââ of the core hanging below the crash bar, and this seemed to work well with the A3 bumper. You can bring it up a BIT more, but any higher and it fouls the top of the bumper and back of the grille, any lower and itâll hang out the bottom!

To mount that I used a length of 30mm Angle section alloy bought from B&Q for about £7. thatâs just secured on little bits of box section either side of the rad. All very simple stuff, you can see pics on page 26/27 of my build thread.

As for pipes, the cold side is VERY easy.

You will need:

1x 76-63mm 90 degree reducer in silicon

1x 63mm 90 degree silicon bends

1x 63mm 90 degree alloy bend

1x 63mm straight 100mm alloy coupler.

Itâll look like this:

Reducer off the core > coupler to join up the next silicon bend, > then the alloy 90 takes you into the standard throttle body pipe. Simples.

As for the hot side, itâs a BIT more tricky.

You will need:

1x 76-63mm 90 degree reducer in silicon

1x 63mm 90 degree silicon bends

2x 63mm 90 degree alloy bend

1x 63mm x 300mm straight alloy pipe

1x 63mm 45 degree alloy bend

1x 63mm 45 degree silicon bend

1x 51-63mm straight silicon reducer to go onto the turbo outlet.

1x 63mm straight silicon coupler.

The layout:

51-63 reducer straight onto the turbo, pointing upwards.

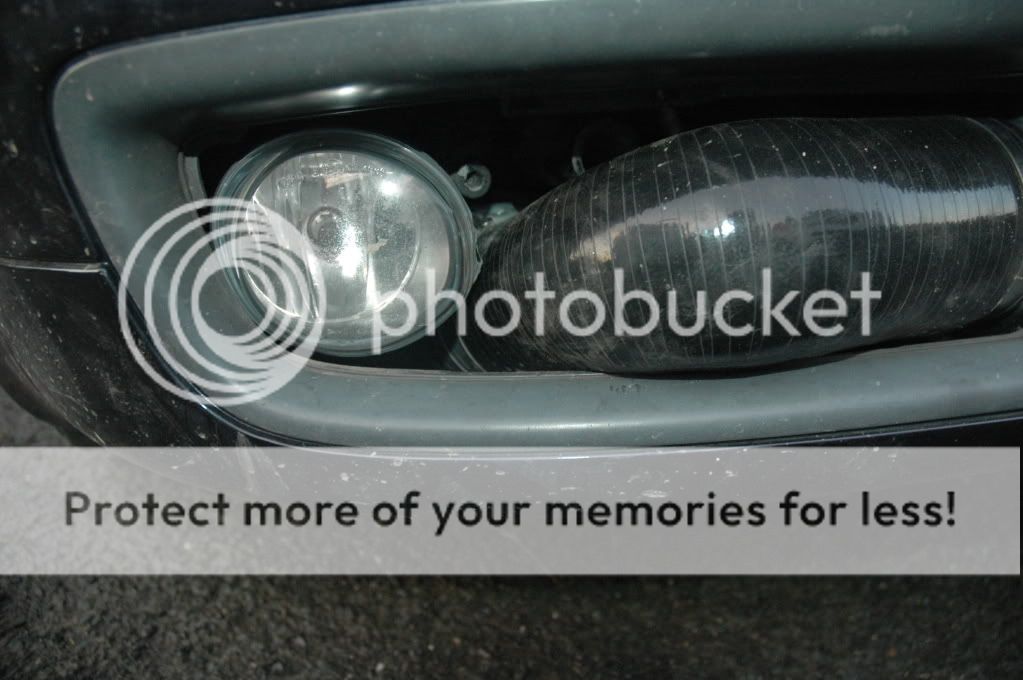

> alloy 90 degree bend into that, pointing forwards towards the pax side headlight. Coupler on the end of that into:

>45 degree alloy bend into that, coming over the rocker cover

>45 degree silicon bend to take the route downwards part the starter motor

> 90 degree silicon bend on the bottom, pointing outwards towards the pax wheel.

> 90 degree alloy bend, takes you out through the side of the undertray side panel, and ends up pointing forwards below the headlight

> into the 76-63 90 degree reducer pointing back towards the centre of the car, and connected onto the core

Top side setup will be very similar to this: (this is my ko4 layout)

Although the connection onto the turbo is slightly different, because your turboâs sit a lot lower than my ko4 frame.

All the silicon bits and alloy bends came from Mr. Silicon on ebay:

eBay My World - mrsilicone

As for the clamps, I used JCS Hi-Grip stainless steel clamps, you need the 60-80 clips for all the 63mm pipework, 2x 70-90 clips for the core connections, and then a 50-70 for the turbo connection. Count the number of joints in the system to work out how many 60-80âs youâll need, itâs about 12 I think.

The core was £80, my pipes from Mr silicone came to £140, and I spent about £30 on hose clips.

Good luck!

Will add some finished pics of mine a bit later on

LOL

LOL