- Joined

- Sep 14, 2008

- Messages

- 24,836

- Reaction score

- 6,078

- Points

- 113

- Location

- Wibbleton

- Website

- www.tuffty.co.uk

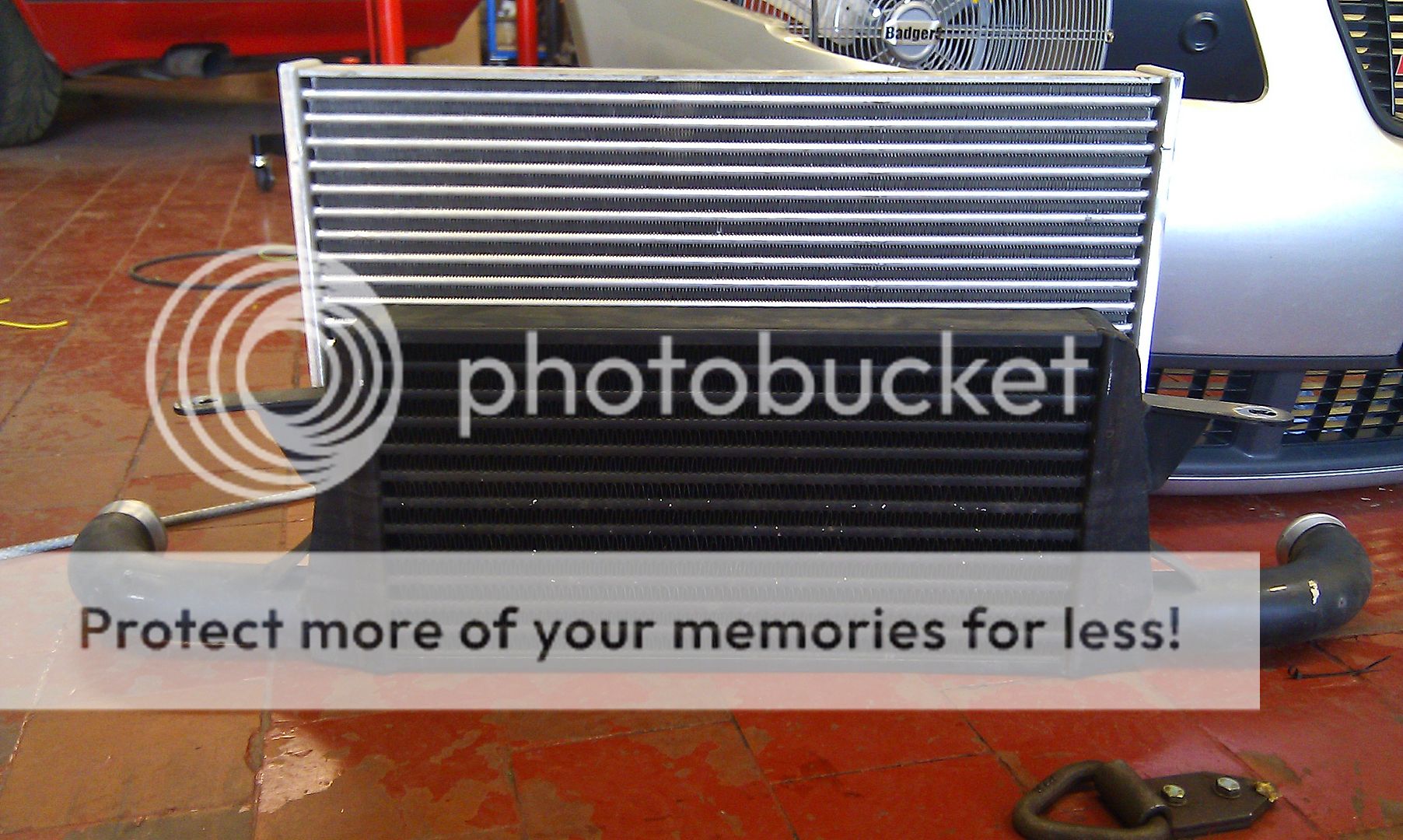

Well I think one of these should be on the cards now then. Cheers for doing the write up. With length do you recommed for the alloy 90oc bends?

Cheers

I used std Forge alloy bends... they come in one length as far as I know... not sure if for the other S3 we cut them a bit and redid the bead or just left them std length... my fabricated ones were cut and bead rolled afterwards...

<tuffty/>