- Joined

- Jun 19, 2009

- Messages

- 3,883

- Reaction score

- 619

- Points

- 113

- Location

- Leeds

- Website

- www.aldevelopments.com

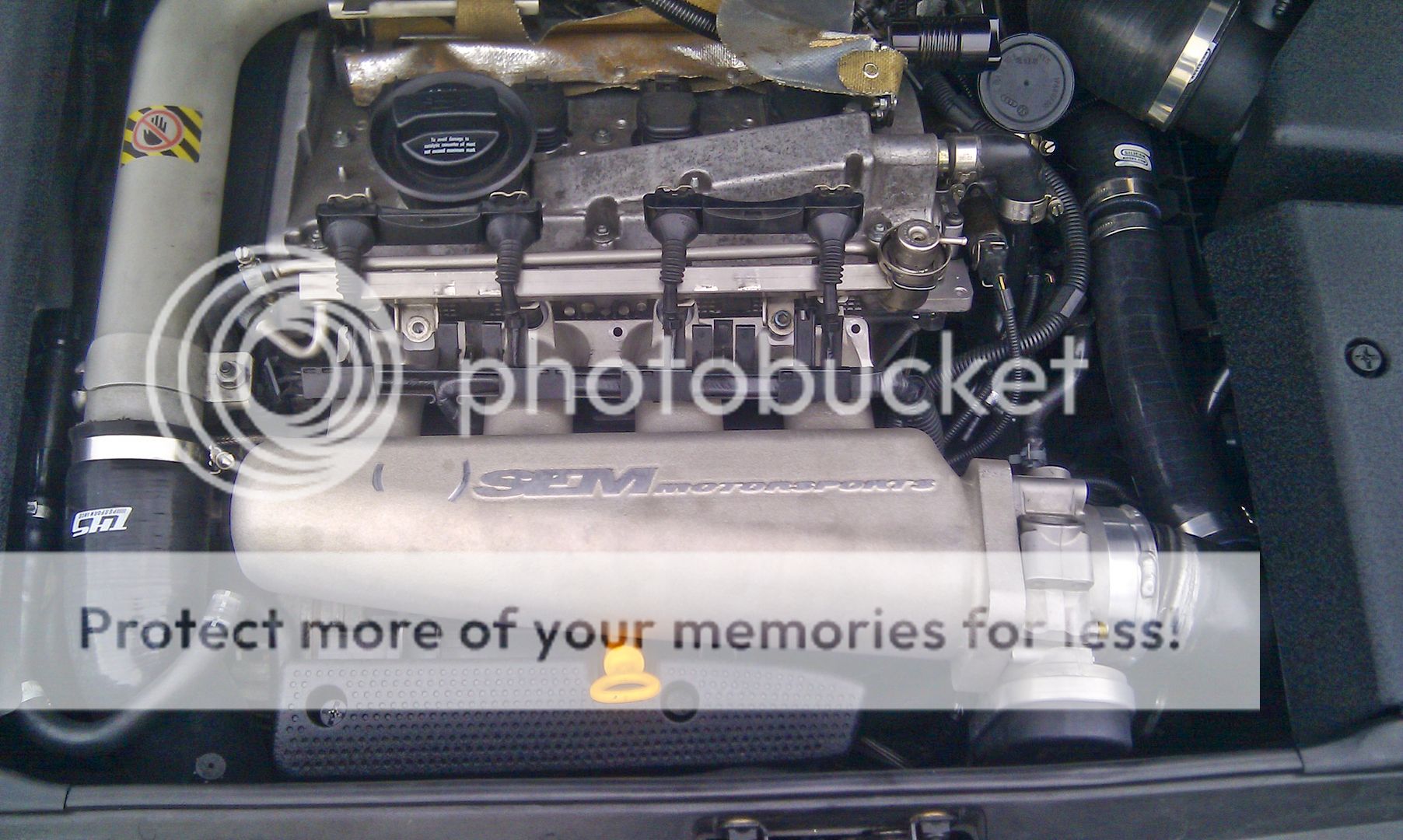

Take one AEB inlet, Cut off the plenum, Order a universal plenum from the US, Get some trumpets from Jenvey, Make up a jig for bosses that hold the S3 engine cover on.

I'm about to machine the base plate to match the ports then i got to get it welded up

More pics to come

I'm about to machine the base plate to match the ports then i got to get it welded up

More pics to come