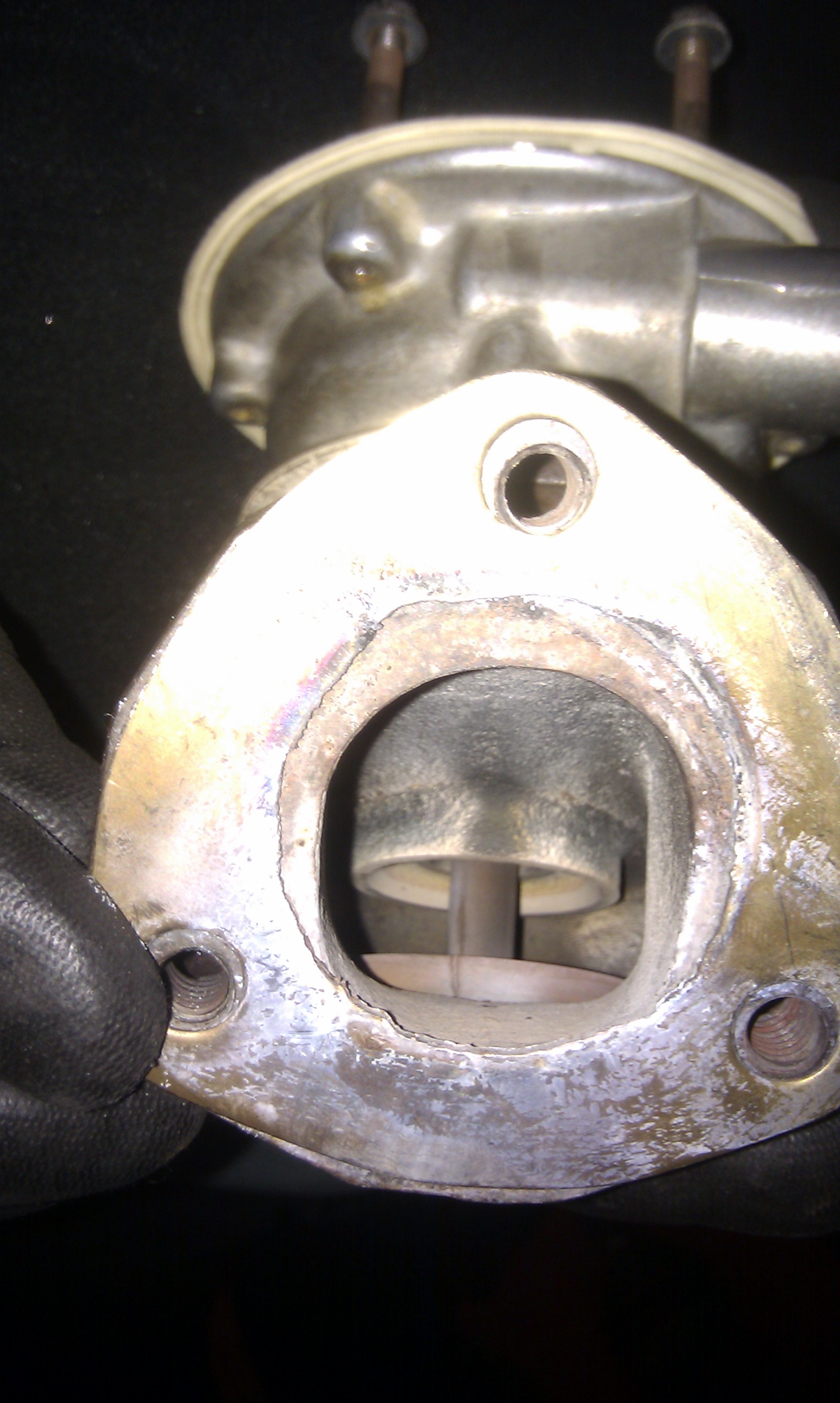

Have just rebuilt my engine and have now got a large port head but after rebuilding had an oil leak on the head gasket at the cylinder 1 back oil gallery so though maybe might have got a bit of ****e in there so thought id give it another go, although the head had just been skimmed but got dropped in transit so thought id get this checked as a precaution and it had less than half a thou run out on it

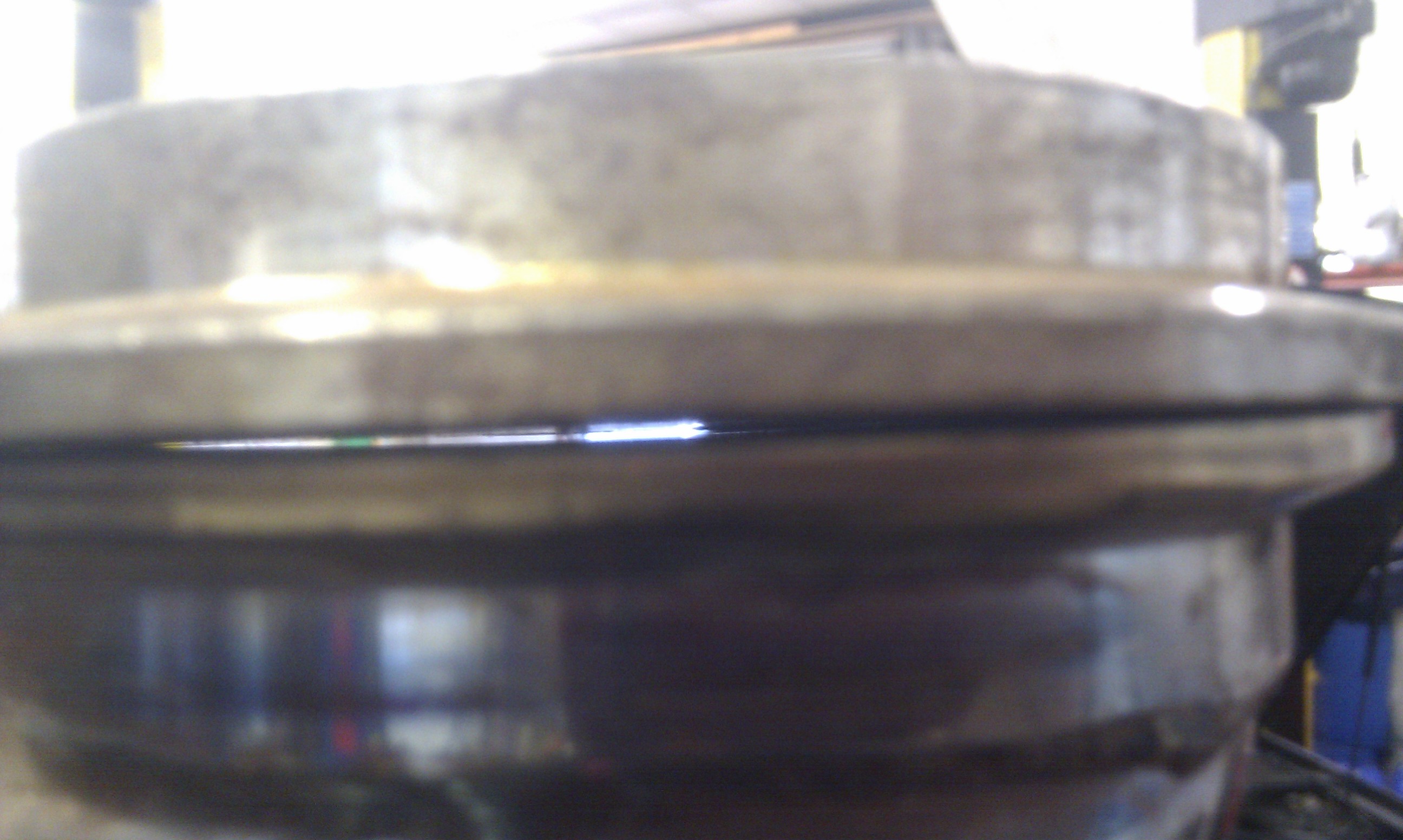

Although the block was still in the car, rather than remove thought the best method was to use a machined bar across the center of the block and run a DTI along it (i know its not ideal but dont fancy stripping everything down just to clock it) the results were very consistant and the max differential i got was 3.5 thou (less than 0.1mm) across the whole block an put it back together and it is leaking in exactly tht same place

a friend of mine has said to try wellseal on the gasket as i used no sealantl but am not a fan of trying to mask a problem and really didn't think that little amount of run off was that crucial??

your opinions and views would be much appricaited

cheers stacey

Although the block was still in the car, rather than remove thought the best method was to use a machined bar across the center of the block and run a DTI along it (i know its not ideal but dont fancy stripping everything down just to clock it) the results were very consistant and the max differential i got was 3.5 thou (less than 0.1mm) across the whole block an put it back together and it is leaking in exactly tht same place

a friend of mine has said to try wellseal on the gasket as i used no sealantl but am not a fan of trying to mask a problem and really didn't think that little amount of run off was that crucial??

your opinions and views would be much appricaited

cheers stacey

Last edited: