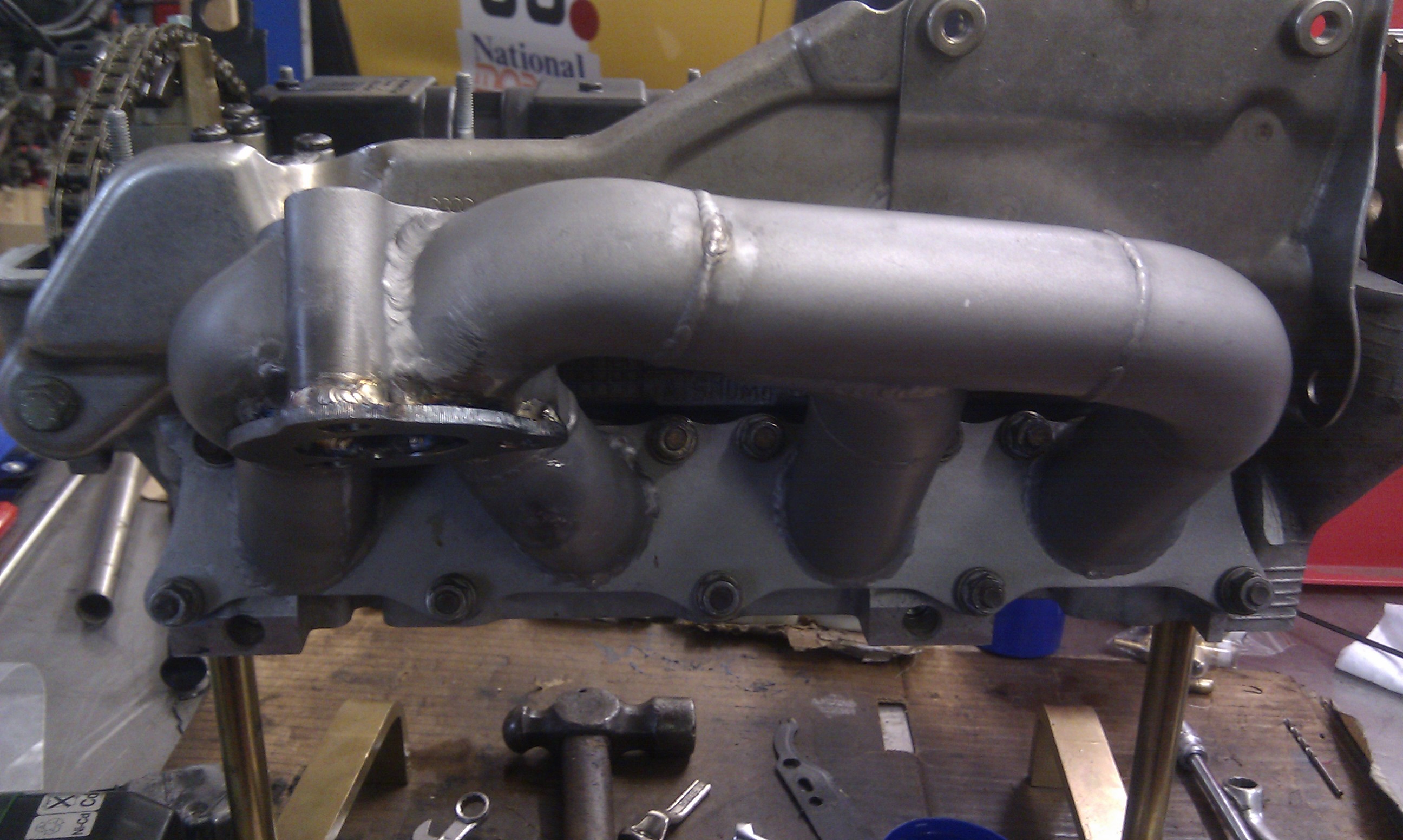

OK, engine built, and bedded in, I have done 1300 miles without going over 3,000 rpm

I get smoke in idle but I think this is unburned fuel because the map isn't set-up properly yet. Driving the car clears this.

My main concern is an oil pressure fault I cant seem to solve then it can go for its map.

What happens once the car has been running for over an hour and got pretty hot is that I get an intermittent oil pressure warning.

When driving over 2,000 RPM (but under 3k of course) this fault never occurs,

When idling this fault also never occurs.

When driving between ~ 1100 RPM and 1900RPM after a 10-20 seconds the oil pressure light comes on. When I take it over 2000RPM, within 5 second it goes off.

When the fault first comes it might not happen for a while but once the car has been running for 2 hours+ it happens constantly when you are in the above rev range.

the engine is not noisy, and drives smooth and as expected.

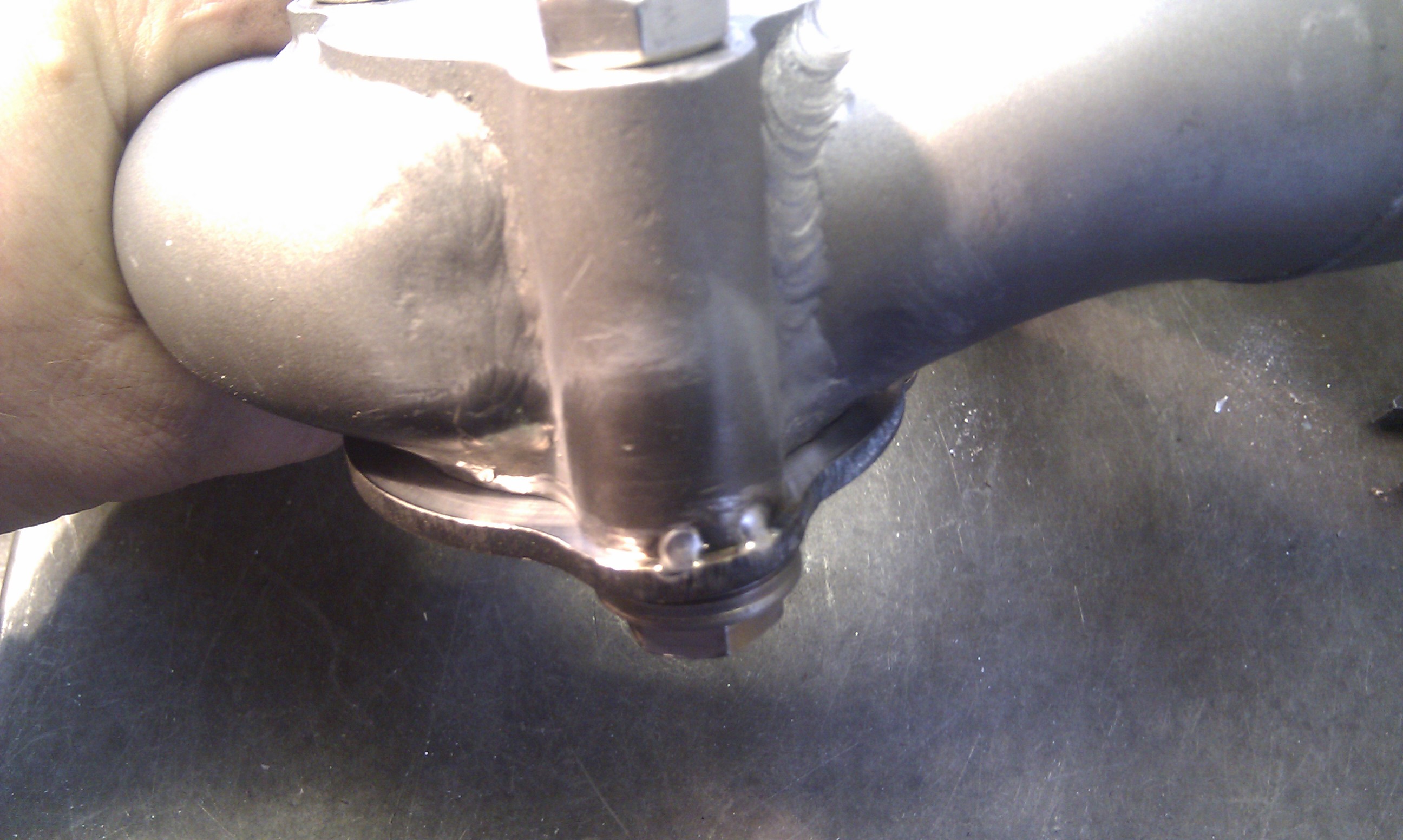

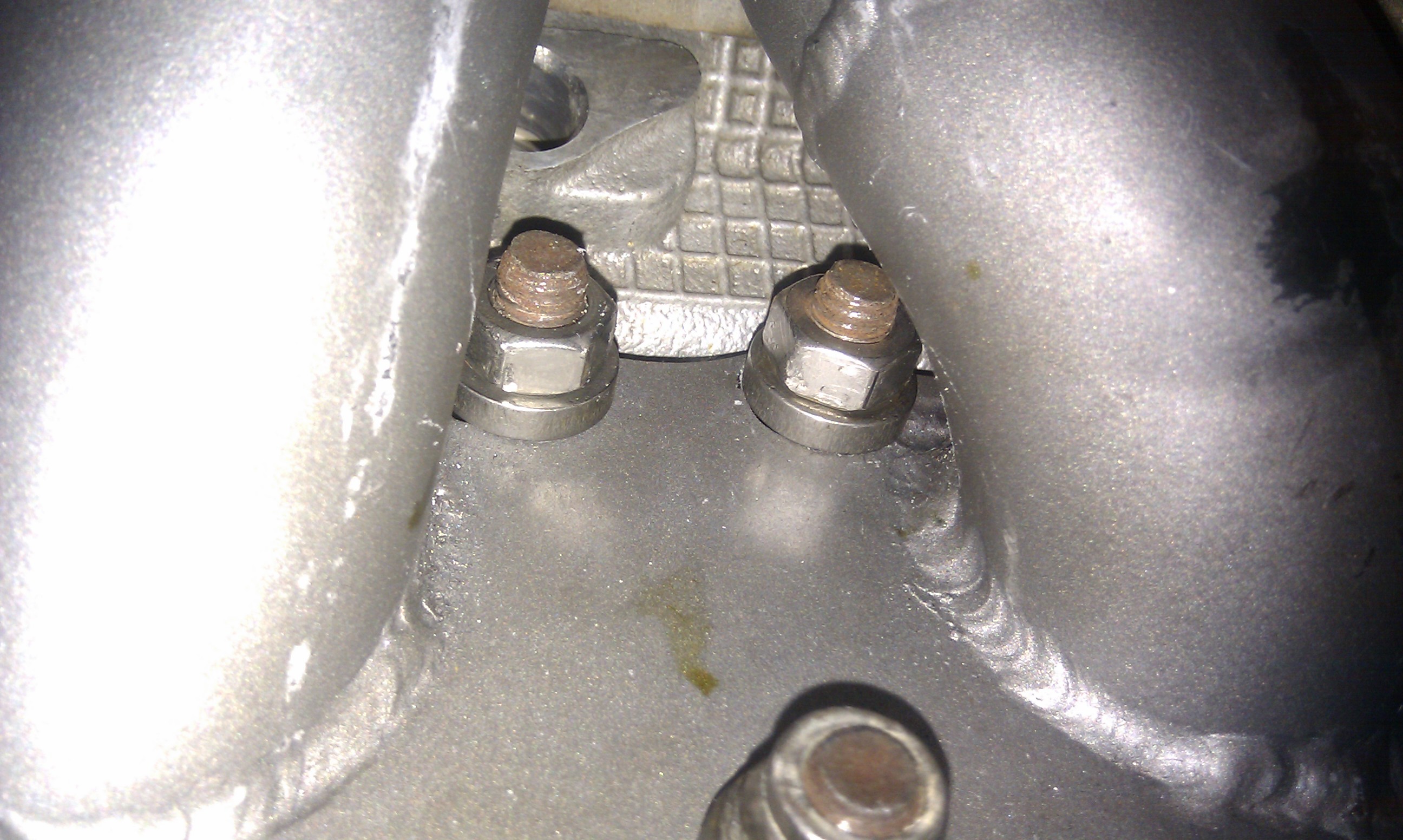

I have since fitted a new oil pressure switch, which didn't solve it, then a new oil pump and pick-up pipe (the last one was clean though, but just to be safe).

The problem remains.

Here is a video :

Audi S3 1.8t oil Pressure Fault - YouTube

Sorry the picture is a bit small by the time I rotated it to be the right way and uploaded it to youtube it ended up like this.

Any ideas ? could it be anything to do with the fact that its not yet mapped for the turbo and injectors ? is it possible the new sensor (bought from BMS) is also faulty ?

My mechanic and my friend both suspect its an electrical problem throwing the warning because there is no sign of problems with the engine. the car has been stood for 4 months waiting for parts and having the work done.

What does everyone thing please ?

Thanks.

/edit, its been on VAG com at various times and never logged one single fault.

....but yes...i am kinda excited

....but yes...i am kinda excited  (hope nothing goes wrong!)

(hope nothing goes wrong!)

.

.