one word comes to mind.......superbikes are'nt quite as quick

9000rpm rev limiter, 208mph top speed

awesome!

i want ago lol

one word comes to mind.......superbikes are'nt quite as quick

9000rpm rev limiter, 208mph top speed

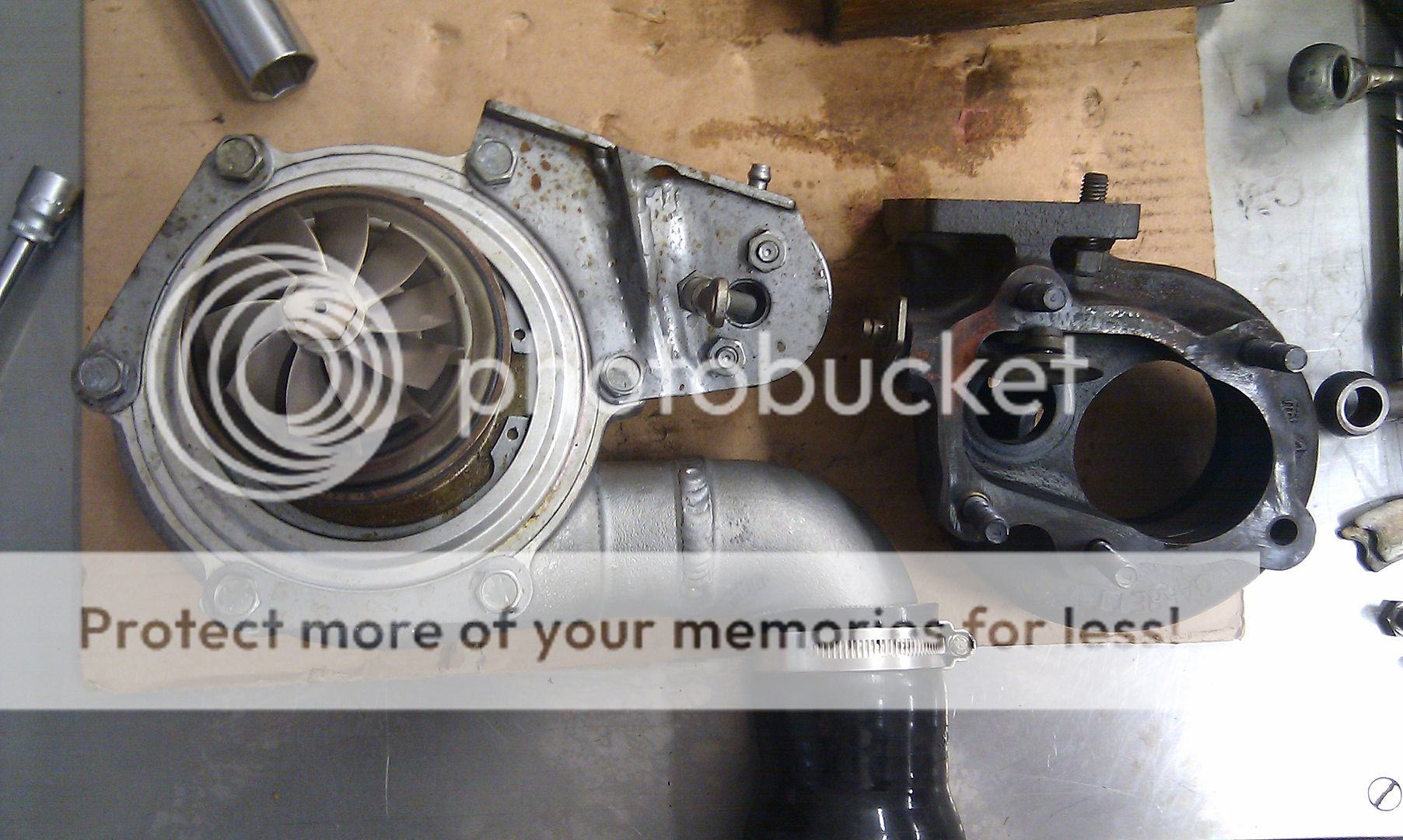

I managed to fit the small port gasket on the largeport side and the largeport gasket on the small port side... which obviously doesn't help flow...DOH!!!!

...Good work getting the head off dude - what's it looking like?

...like the pics and write up in the earlier post... lol

<tuffty/>

I never thought about putting my pump in the wheel well

Shame you can't hide the water tank in there unless you get a custom made one?

Wish my head looked that clean..... lol.

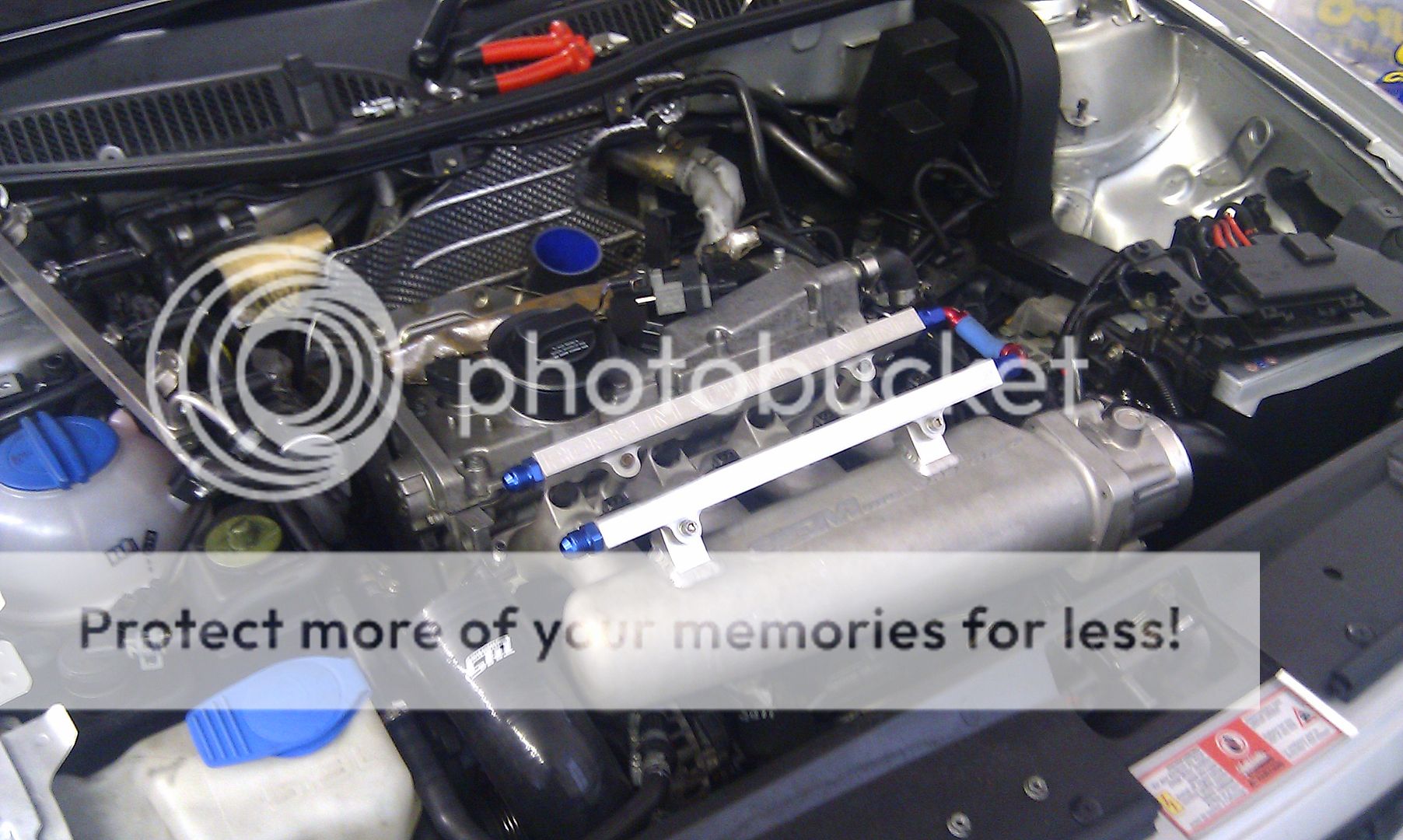

2 Sets of injectors? Cool , what manifold is it? Off bills car I'm guessing?

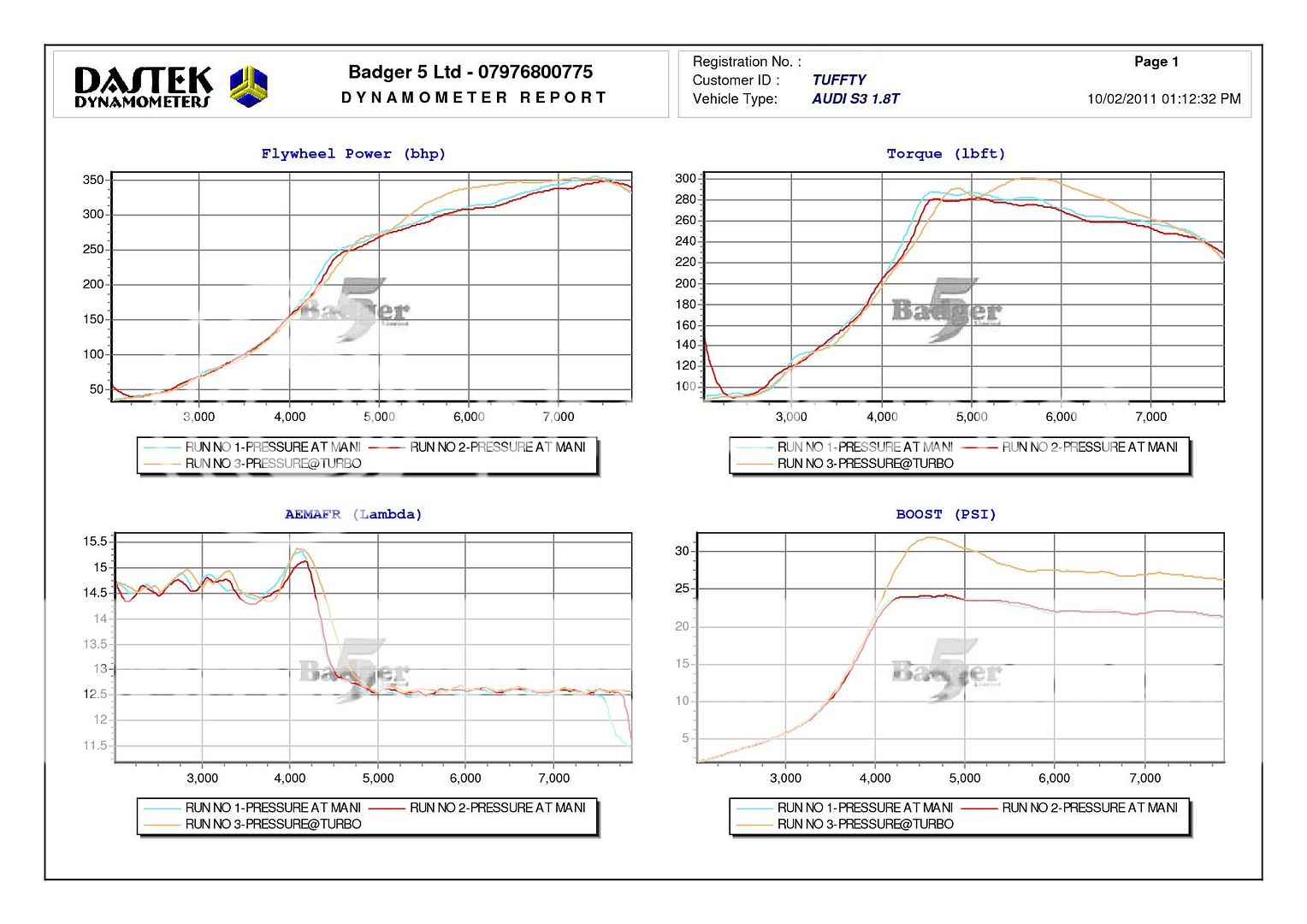

I doubt you maxed the MAF, more like maxed out VCDS.

The MAF should read to around 340g/sec, whereas VCDS stops reporting just under 300.

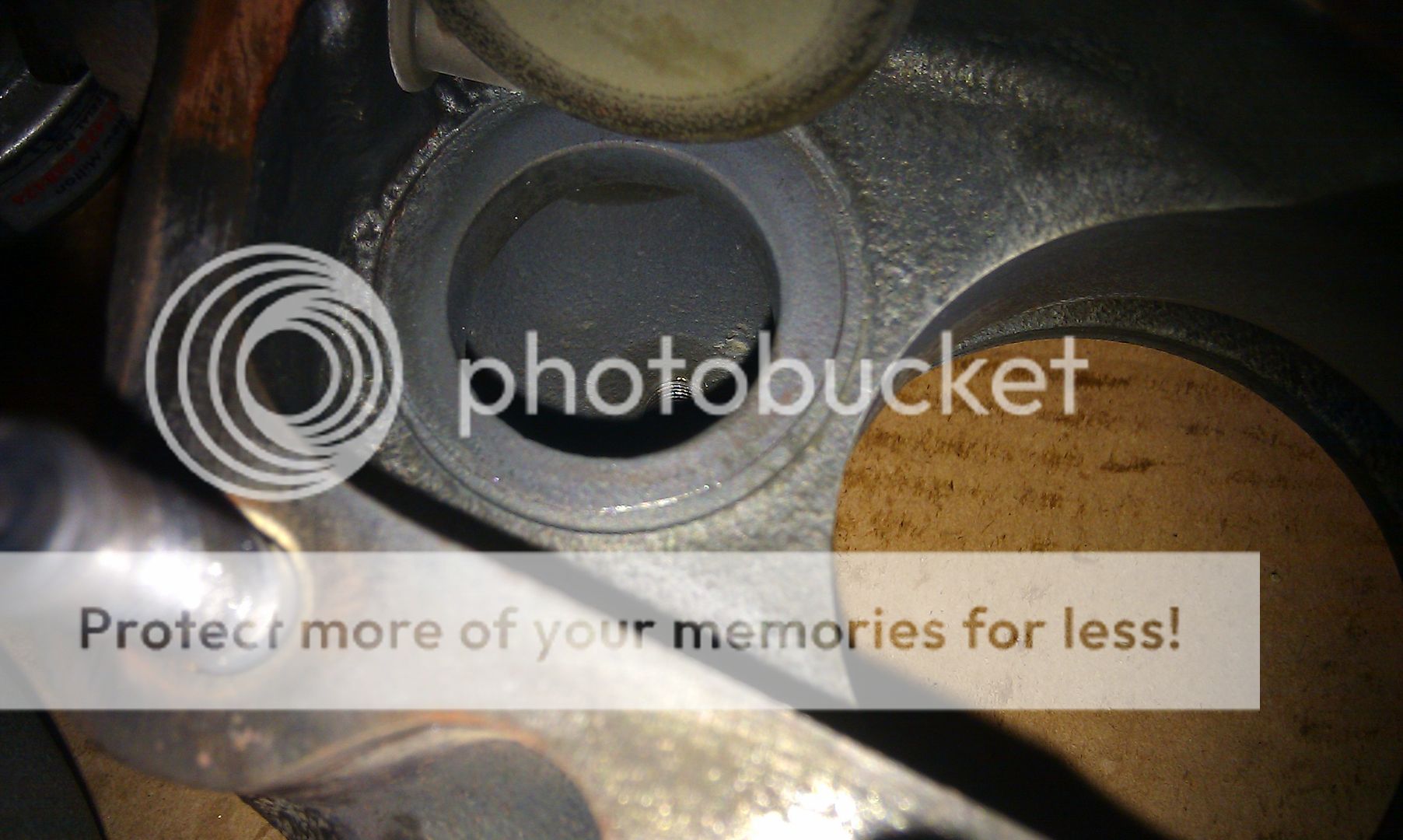

Oilpressure isnt good, but i maintain that ALL tuned 1.8T's should have a pressure guage. The built in warning is absolutely hopeless. My old 1.8T A4 had only 8psi at hot idle, and would manage about 1bar per 1000rpm when revved. This is miles below spec, and 8psi at idle was enough to set the lifters clattering, yet the pressure light never came on. It wasnt sludge either, just a worn oil pump, the pickup was clear. The replacement engine with a new pump would see over 15psi at idle, and was showing 5bar by just over 2k.

What oil are you using? If its 5w30 get shot of it, as it thins down too much when hot further reducing pressure. With your engine i'd probably be looking at a 50weight synthetic, although a 40weight will probably be fine if most of your driving is "normal" rather than full bore.

Minor fail of the day seems to be my rattle that I thought was the cam chain tensioner... still rattling but for a different reason I think... oil pressure... there is pressure there (but have knocked the dyno runs on the head for the time being) but when the oil gets hot I get a fault appear (16395/P0011/000017 - Bank 1: Camshaft A (Intake): ****** Setpoint not Reached (Over-Advanced)) so thinking the pressure on low revs isn't high enough... I did test drive the car after she had cooled down a bit and the code hasn't come back yet...

<tuffty/>

Mass air flow - S4wiki

That suggests the S4 sensor in the same 73mm tube will read to 364g/sec.

You yourself in another thread posted that the stock S3 map has ~340 programmed in, and that occurs at only 4.88 volts (iirc).

Its a known issue that Vagcom cant read out to these sensors maximum values. The S4 Wiki shows the limits vagcom will read on various S4 ECU variants, so theres no reason to think the S3 will be any different. A DMM on the sensor wont neccesarily be accurate, unless its tied to the same signal ground the ECU is using, and most DMM's wont react very well to a rapidly changing signal such as that the MAF outputs.

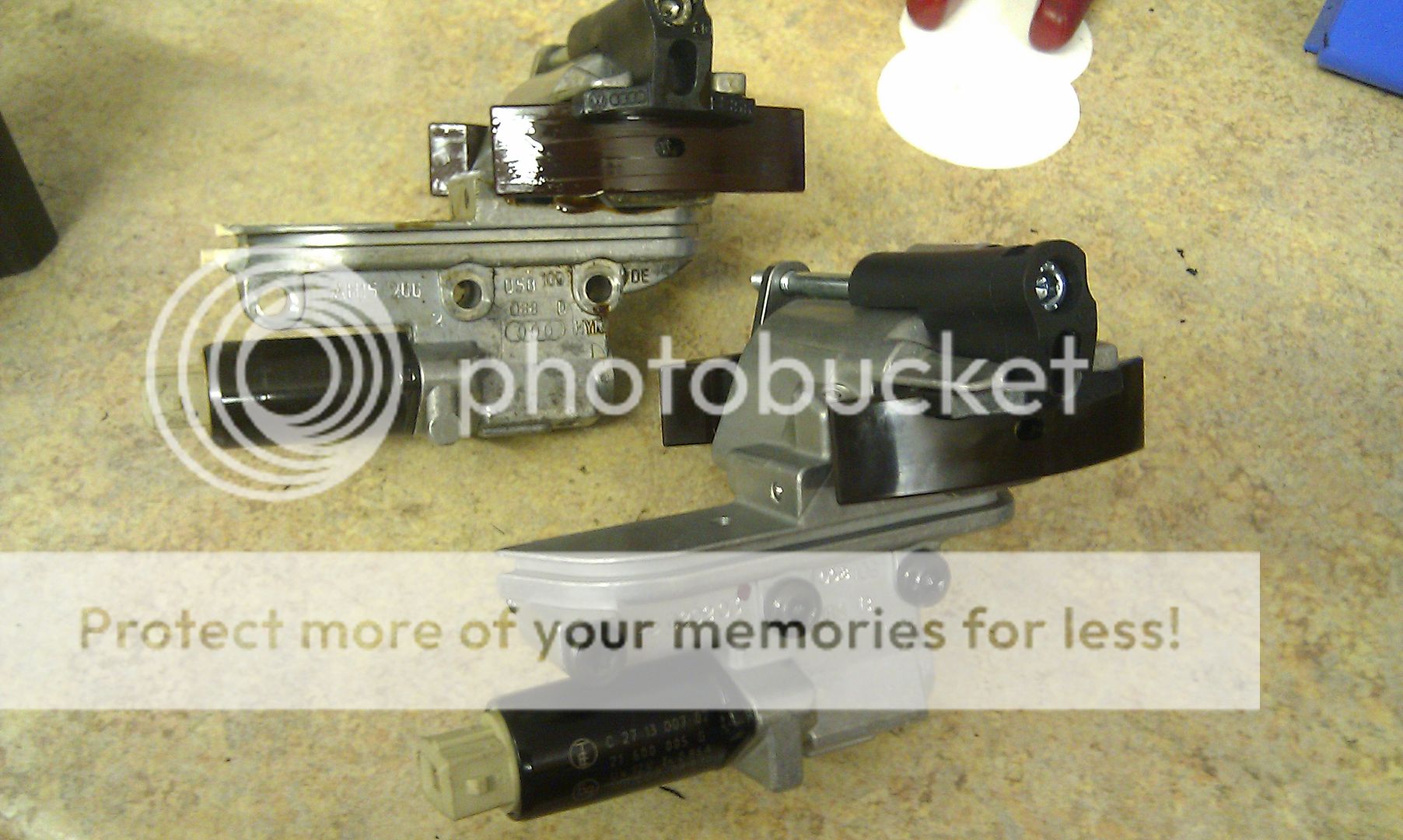

Paul, I had that code on my car for ages and done loads to it to get nd get rid of the code and it turned out to be the actual VVT unit. I didnt think it would have been that as it was a brand new one from ebay so ruled that out.

I changed the oil pick up twice, change the oil pump and had my oil pressure checked and all was ok and even re done my timing but still got the code once the oil got hot. Put my old OEM VVT back in and the code never come back "touch wood". You can check your oil pressure on vag com but just say if oil pressure is ok or below minimum.

If the code reappears put your old VVT unit back in before you chane any other parts.

How do you check for preasure drop over the FMIC?

I would like to do this with mine