So far today, good progress....

Photo of the head last night ready to fit...

Started today with taking the engine mount off, resetting the tensioner and refitting.

That's all sorted now, combined with the new belt on waiting to be fitted.

Took my intercooler pipe up to Bill so he could weld in a boss for my WMI... (thanks Bill - again :thumbsup

. Anyway, he had that done in a very short time indeed, so I was off home before long.

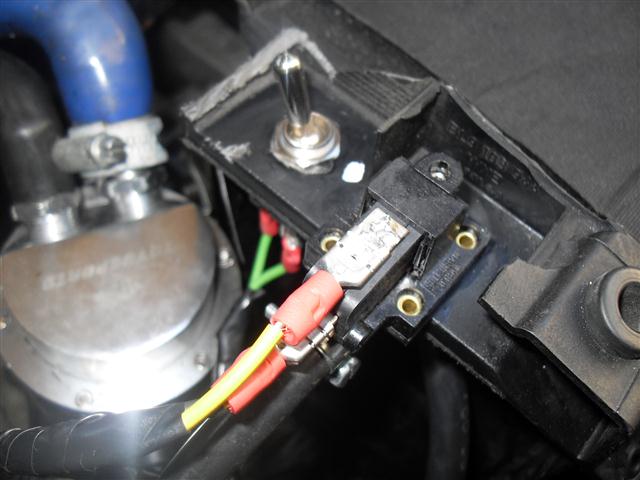

Refitted the intercooler pipe to the car, and threaded in the WMI nozzle and check valve with a bit of instant gasket to help it seal.

I started running the pipes then, and fitted the WMI pump to it's new home. Made a bracket to make it fit, and bolted it in to see how it fits. Really pleased with the result :thumbsup:

Then decided to see how easy this head would be to get back on with the manifold bolted up, and more importantly, how hard the nuts would be to get onto the studs...

Difficulty - easy. Time taken - ages.

This was easy once I had devised the right tool for the job. I went and mangled an old 17mm spanner into the right shape for the job... Photos below for reference.

One of the nuts is very hard to do up as we know, I have got it as tight as possible, however only time and the engine running will tell if it's tight enough... Fingers crossed.

Finishing up the night, the engine bay looks like this:

There is tons of space where I modified the heat shield, so I am really pleased with that. Tons of room, but it's still protecting all the important stuff... Shibby

Shouldn't take long to get it to the point where she will be able to run, but then I've got to drop the sump afterwards and change the pickup pipe.