What number BKR7E'S do we need for our 1.8t's? There seems to be a few variations.

Just plain BKR7E i.e not the BKR7EK

What number BKR7E'S do we need for our 1.8t's? There seems to be a few variations.

The "code" is the supplier s number, the plugs are just as listed.

I use the Eks too as they are twin electrode so don't need gapping.

Copper all the way for me as they handle the heat better but last less time. I just change every other oil change

I have also decided that the time has come to change my oil pickup pipe inside the sump... Top end is beginning to get a bit rattly, and I suspect that this is the likely cause.

Have you done the oil pump, tired oil pumps can also cause noisey tappets. Might aswell change it whilst the sumps off " would be rude not to"

OK, change of plan.

Bit concerned about this whole thing so I am going to take it off the road tonight and use the woman's car to get to work for the rest of the week, and anywhere else I need to go.

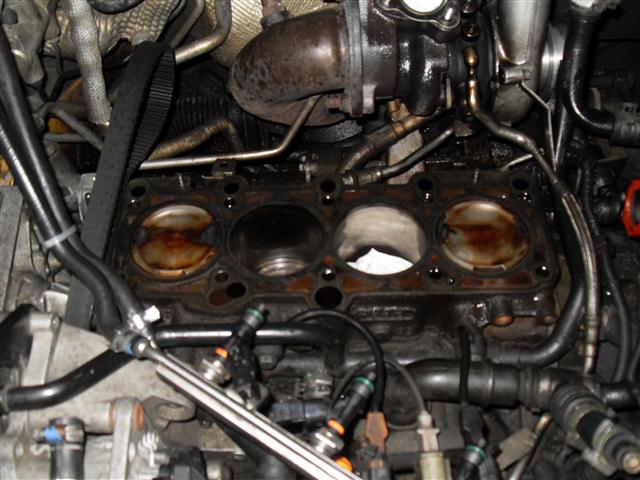

Going to start taking it apart tonight I think, as want to see what's what when I lift the lid off.

My FPR pipe had a colossal split in it when I looked yesterday, and so I want to make sure all is OK piston and valve wise.

And so it begins again.

A bit more in depth this time though as I will be having a good look up into the block whilst the sump is off...

Will take photos tonight.

Hope the pistons/valves are ok Welly, just when you think everything is going well something else happens!

Bit off topic but is it easy/possible to put a knock sensor on the 1.8t's

i have ordered an aem wideband gauge to have in stock welly....

i have ordered an aem wideband gauge to have in stock welly....

Easy to install Bill?

Can you get hold of this one > VEI Systems -- Intelligent Vehicle Instrumentation -- Products: Instruments

Like this? AEM WIDEBAND Universal Lambda Gauge Kit - NVMotorsport on eBay (end time 21-Feb-11 14:24:00 GMT)

Why do you do it to me???

AEM one is..Easy to install Bill?

Can you get hold of this one > VEI Systems -- Intelligent Vehicle Instrumentation -- Products: Instruments

AEM one is..

weld an additional lambda bung in DP and wire it in

I am not a fan of digital boost guages.. they constantly flick between digits.. give me good old analogue any day for boost

Just to let you know you can get oil pumps for £55 from GSF, changed mine a little while ago.

i know I went for 7th once when I hit the limiter in 6th in ickle ibiza a few years ago playing with superbikes on an early sunday morning

Wicked. Get that car working!! lol

pictures!

what happened to ur HD movie excitement lol

I'll take some I promise. Been a bit lazy with the camera lately...

In all seriousness though, are you doing the pickup pipe?