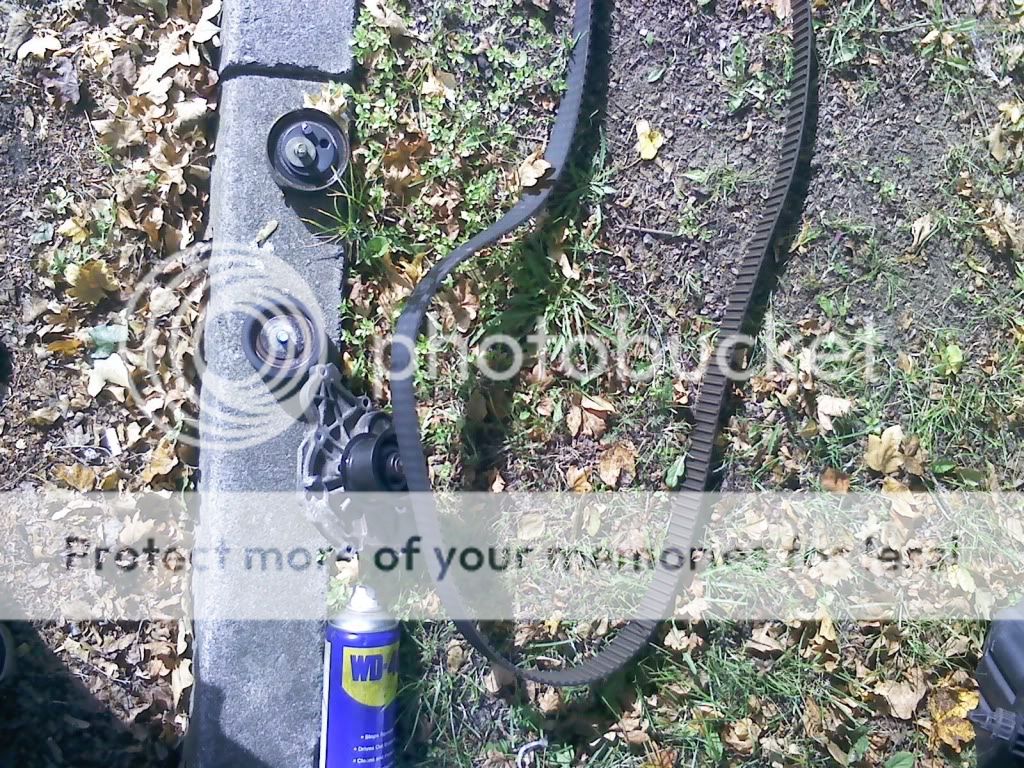

Hi all does any one out there have any details about the head gasket, cam replacment and cam belt (Basically a top end rebuild) on a 2.5 tdi AYM engine ive sent the heads off for skimming and pressure test and have bought new cams, head gaskets, cam belt kit, water pump everything you need for the job it is totally stripped down bumpers and rads out to make it easer to work on. My problem is that there is hardly any info on this i bought a manual for this engine the only one i could get but it is in french so stuck! Does any one have elsawin or similar that could help