Had the car on the dyno this afternoon (thanks Bill :thumbsup

and there are a few things to sort out.... Firstly there didn't appear to be any preload on the actuator and the actuator itself is a higher rated one that I had on previously and I was getting boost creep at high revs.... I adjusted this and hoping the actuator will go a bit softer (which they do) after a little while... using the softer of the 2 springs on the UNOS and getting a steady 1.5 bar but.... did a check on the boost pre FMIC and after (manifold pressure) and there is quite a drop... some can be attributed to the FMIC itself which is normal but a little higher than expected but there is a big difference at lower RPM as the turbo spools.... Bill has all the logs and the figures etc so I cannot really say much more than that at the moment but one thing he does think is an issue is I could be losing boost through the DV initially then after its caught up with itself all is better... so I an going to try a stiffer spring, Bill had to do this to a similarly specced (albeit a stroked 1.8t to 2ltr) Leon recently...

Bill also found that I was getting no timing pull so dialled in more timing advance and was upping the power all the time until the ECU had a paddy and pulled 11's!!!! not good!

So just reset back to 0 additional advance (over what the map has) and going to start again... the fuelling isn't too bad, wideband lambda helps out a bit here too... it is going very rich at high RPM though killing the power which is a shame... this could well be map related...

Basically spent the afternoon gathering data to see where the map needs tweaking and to see why power is still a little off... few more things to try bearing in mind the map wasn't quite finished before and I have changed quite a bit of the engines characteristics now with the large port head and larger turbine etc so its to be expected...

Car is running ok normally although a little iffy under boost atm... didn't show so much on the dyno but on the road its noticable...

...and I washed the car ready for ADI tomorrow

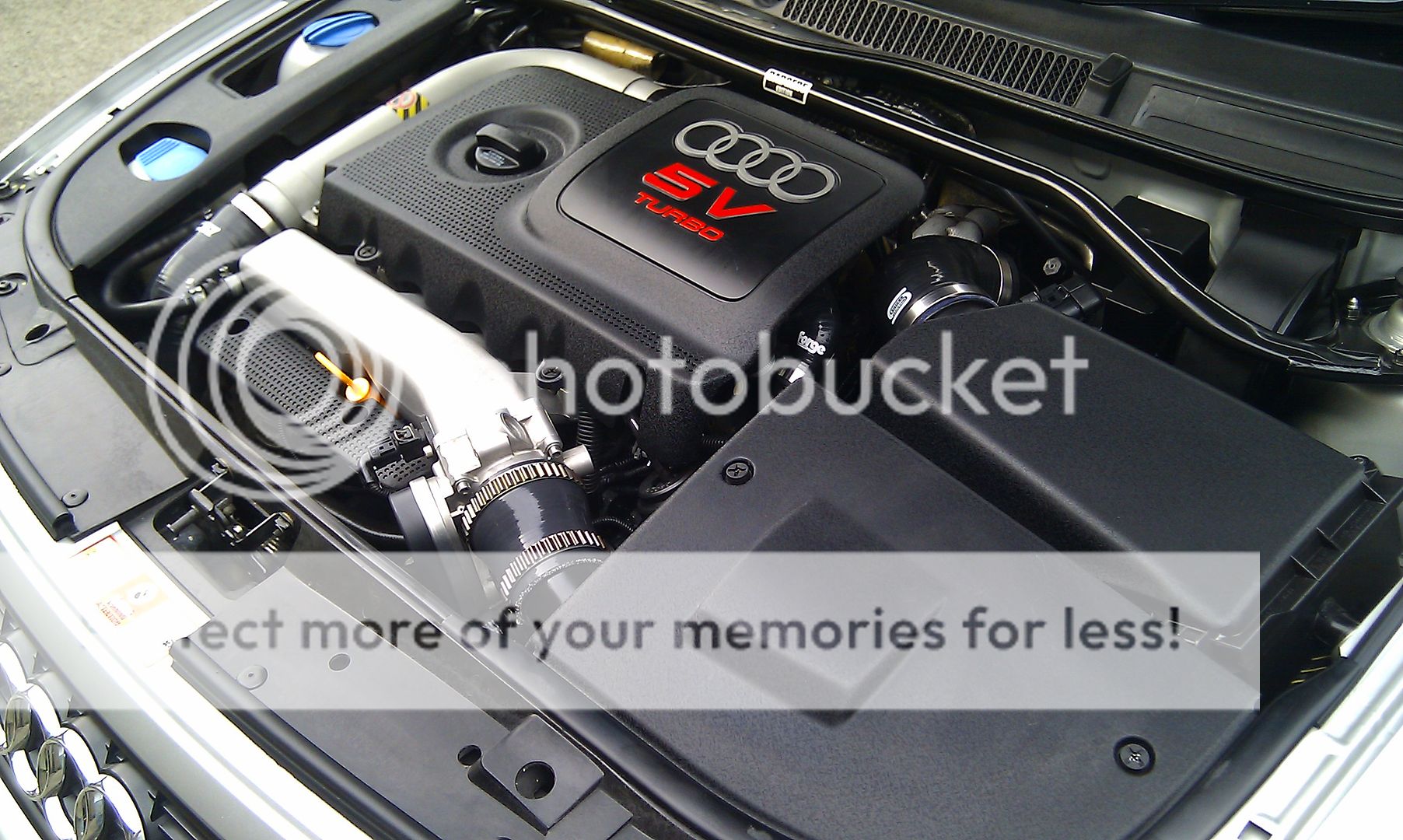

Couple of shots of the engine bay with the SFS hose fitted...

SFS even sent me a matching Murrays clip for the other boost pipe which I fitted when I got home...

See you all tomorrow at ADI

<tuffty/>