Been fighting man flu all day but more or less did a 12 hour stint on her today...

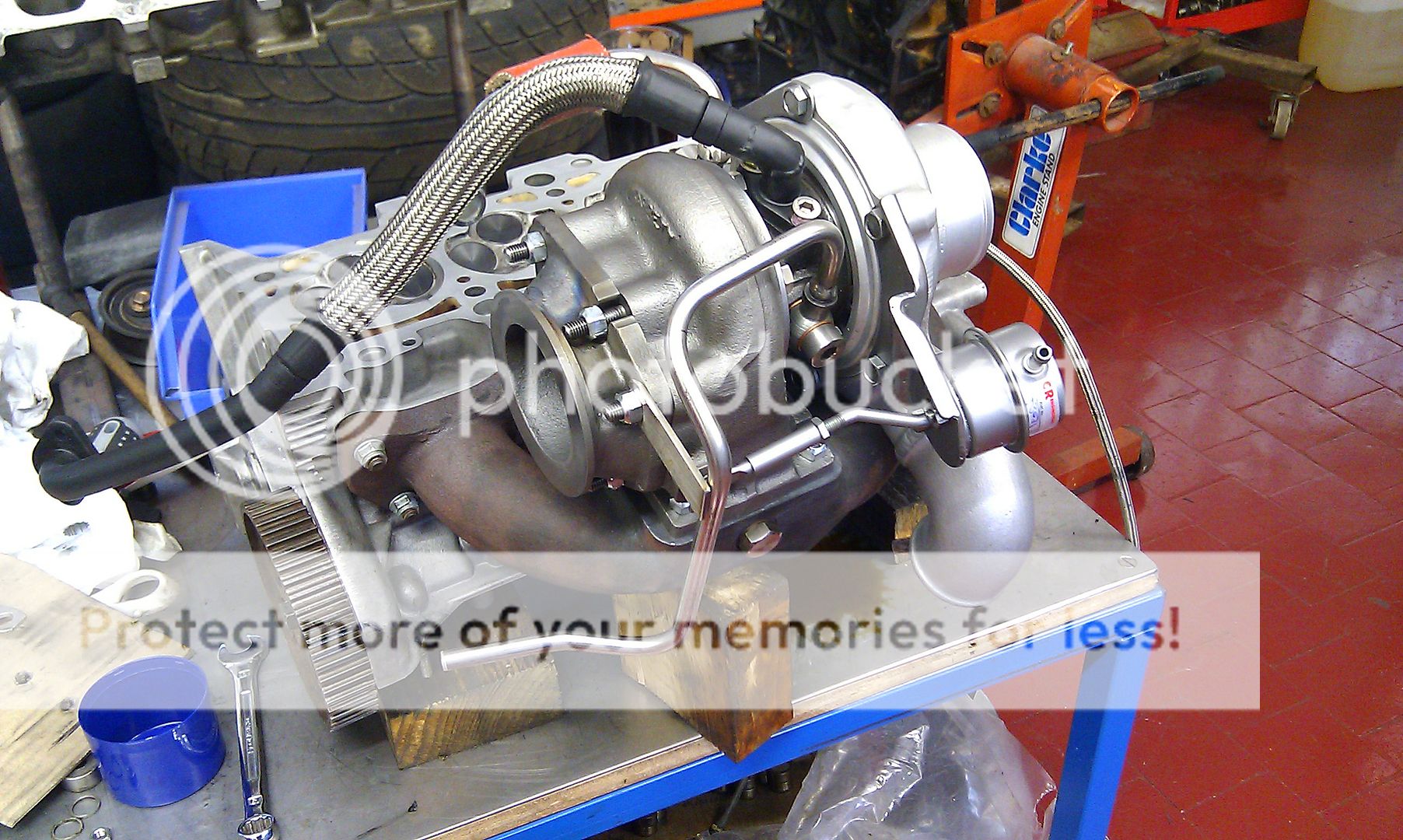

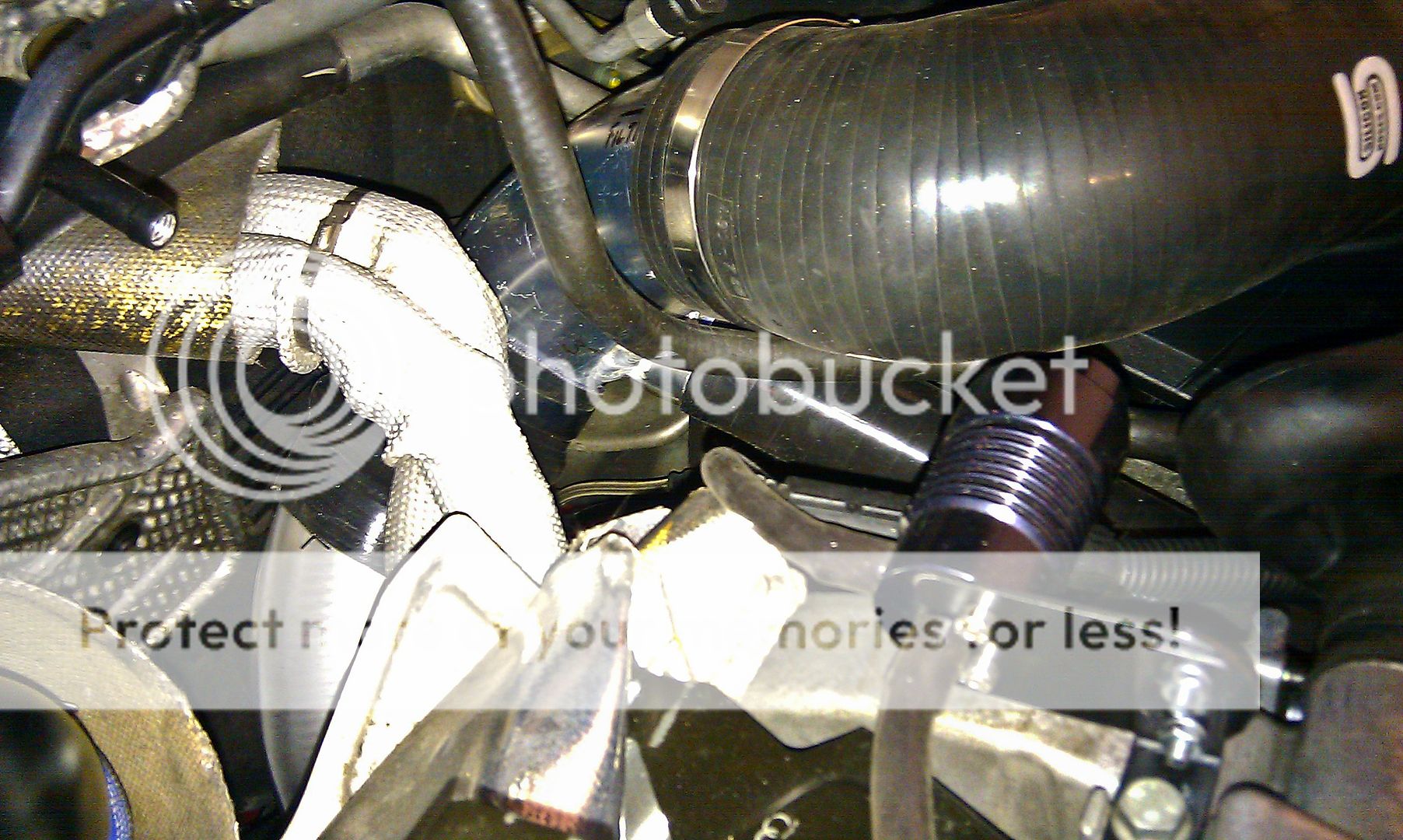

Lots of fiddly stuff and mundane stuff to do but basically went from left to right across the engine bay putting stuff back, changed the oil filter and filled the engine with oil, filled the gearbox with oil as it was drained to remove the bevel box, plumbed in the coolant hoses, EGT probe, downpipe, exhaust, driveshaft, propshaft yadda yadda... all seems to take time to do but all must be done...

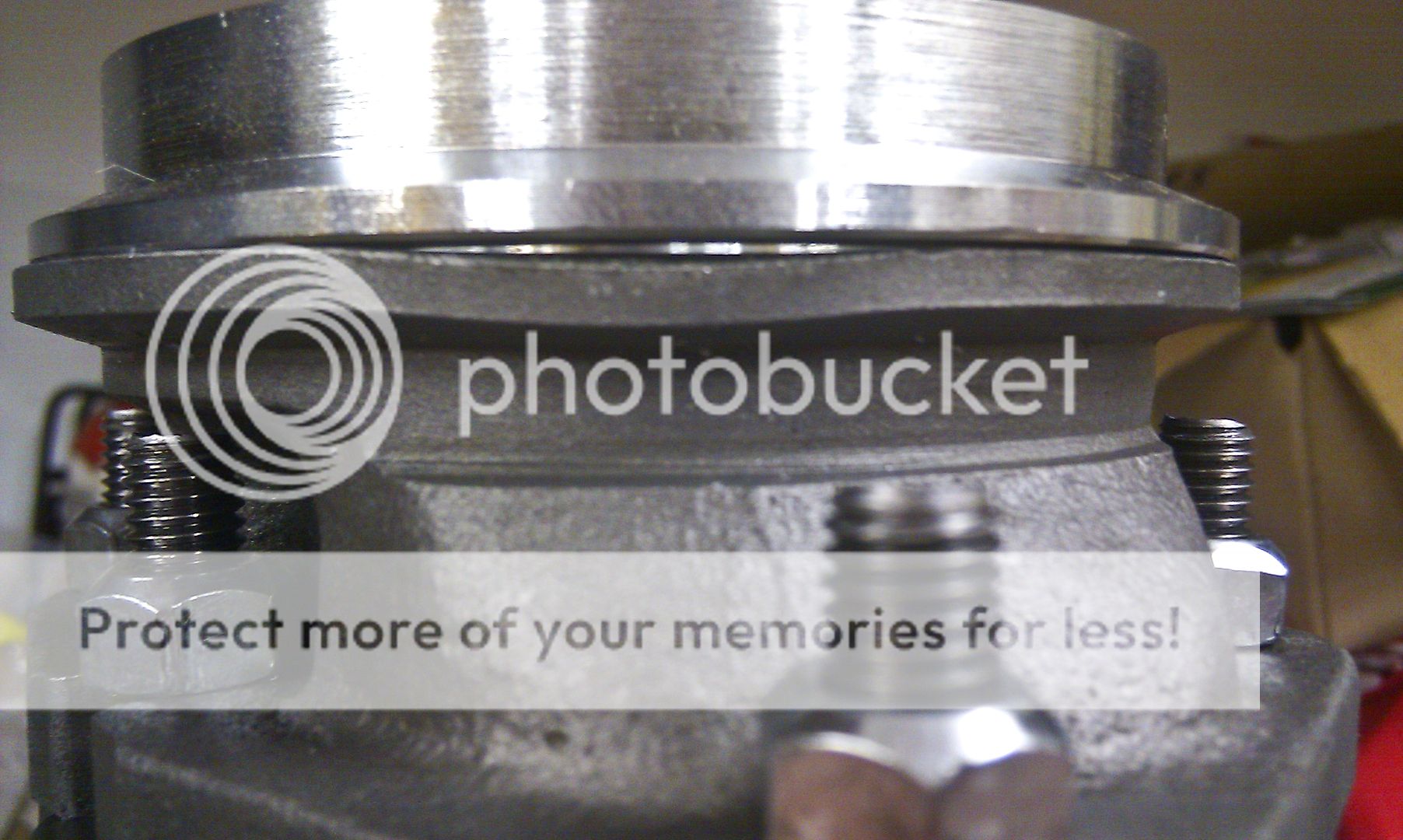

One of the things I did this time around was to simplfy the PCV system... I had already removed a lot of the hoses etc under the inlet mani but sorted it out properly this time as I had the access...

Replaced the lower PCV valve and t-piece with a bit of hose... I used silicon but rubber will do and silicon that is fluorosilicone lined would be better but it will do for now...

...only pipes coming out of the bottom of the inlet mani now is the large one for the DV and the two smaller ones for the FPR and boost gauge...

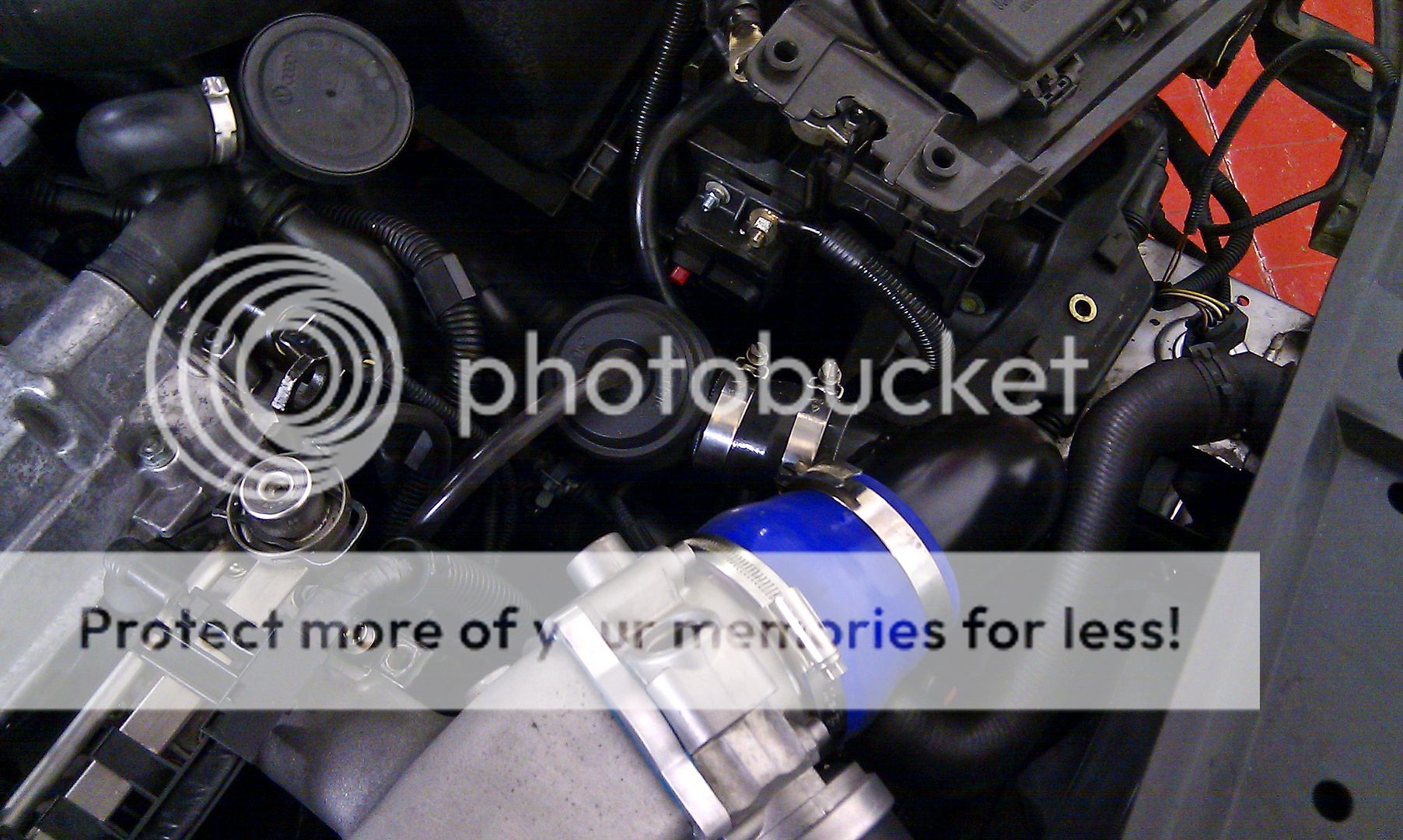

...I have had to use an incorrectly sized blue joiner while I wait (still!!) for the SFS one to turn up!!!... needed everything in place to sort the DV fitment and TIP fabrication out.

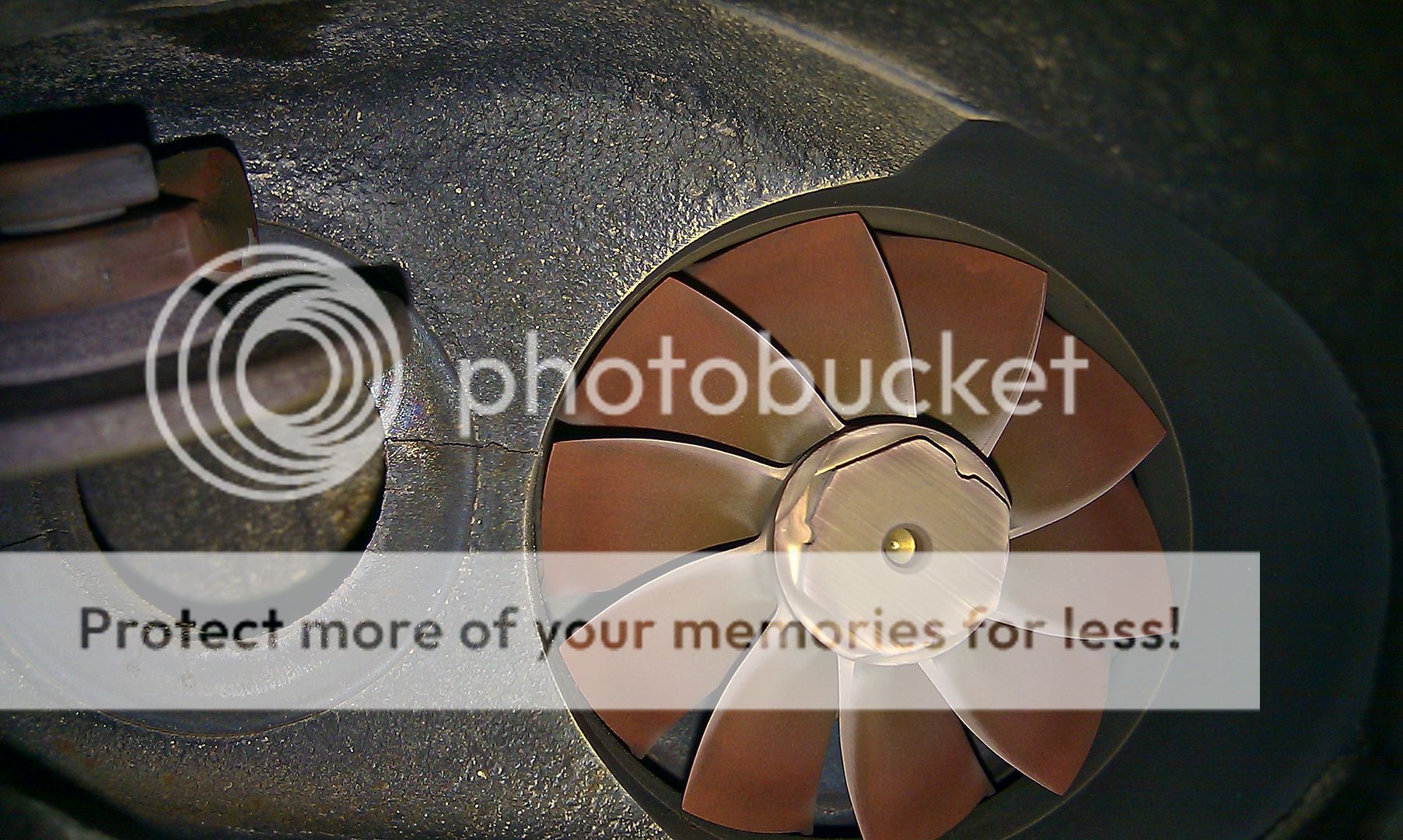

DV in place...

...and pipework from the DV...

...too the TIP...

..this is now the only inlet going into the TIP, all thats entering the intake system now is air and fuel...

A few little jobs left to do starting with painting and fitting the TIP properly... engine bay looks more or less back together...

...FMIC is looking neat and stealthy...

...and of course I couldn't resist checking to see that I still have an OEM look... (despite the blue joiner!!!)

Nearly finished, been tiring and I am royally knackered right now.... up at 6:30 in the morning

Hopefully get to start her up Tuesday night... and I must remember to bleed the clutch!

Again big thanks to Bill for welding my DV inlet to the TIP and of course for his continued support of my modifying habit (which in fairness he did start... sort of... ok, it's always been there!!!)

<tuffty/>