jamiebennett81

Registered User

Standard spec:

Standard spec:

2001 Black magic Seat Leon Cupra

Full black leather interior

Electric front seats

Electric folding mirrors

Electric windows all round

rain sensitive wipers

Auto dimming rear view mirror

Any other usual extra's

Modifications:

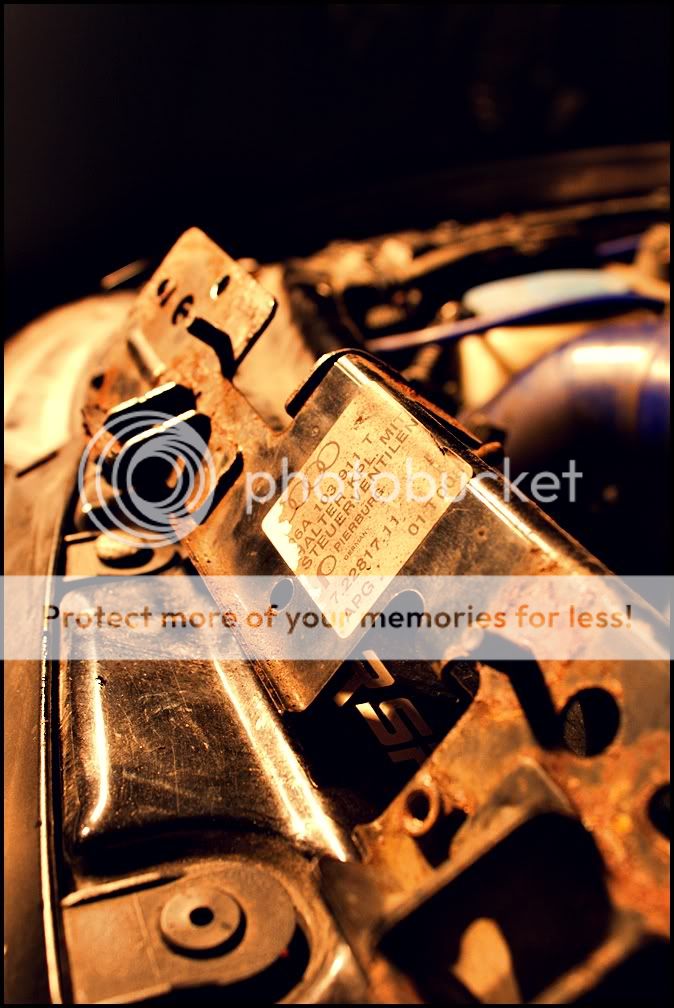

Engine

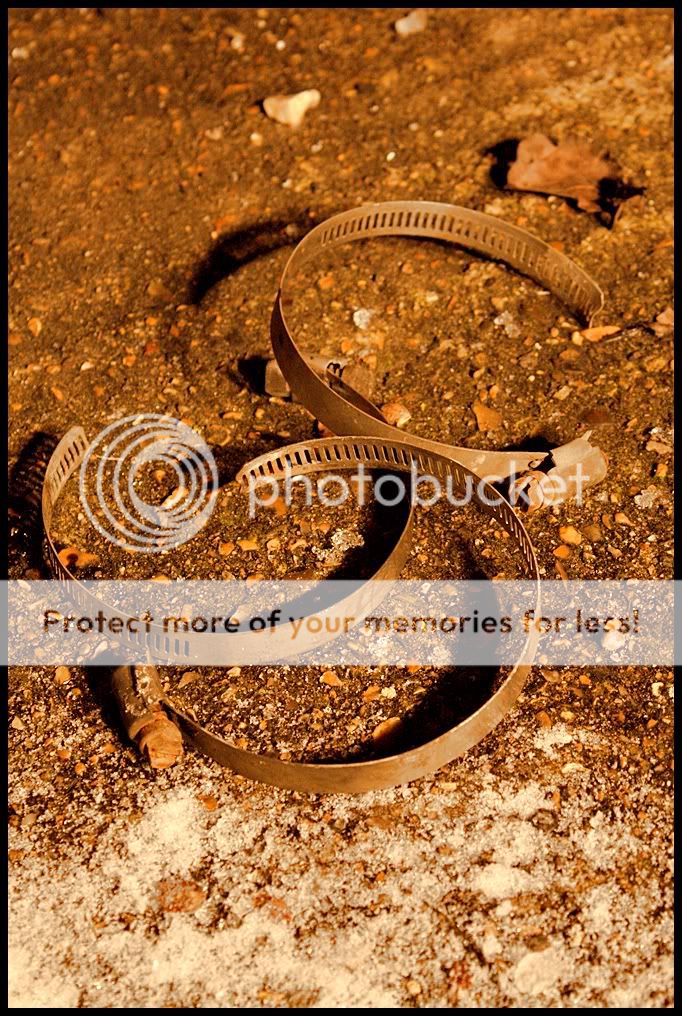

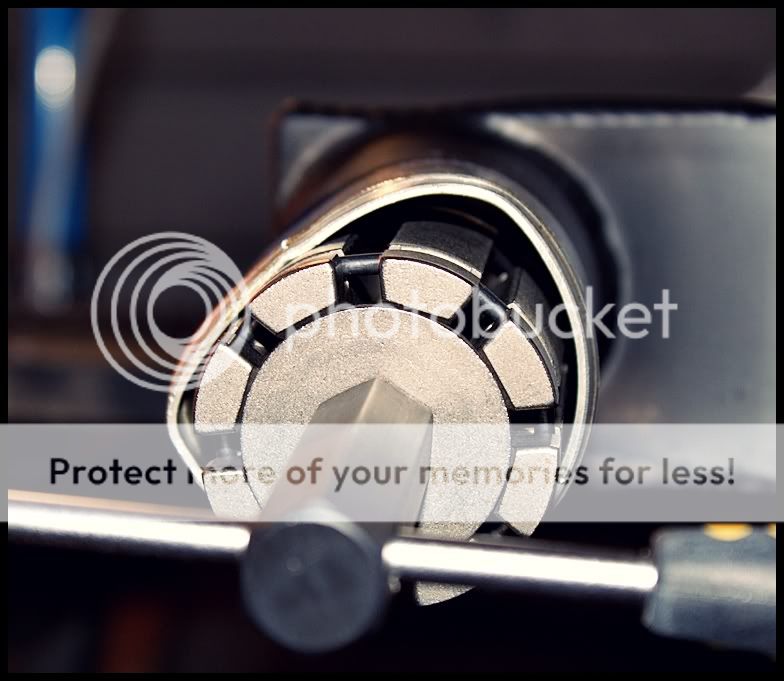

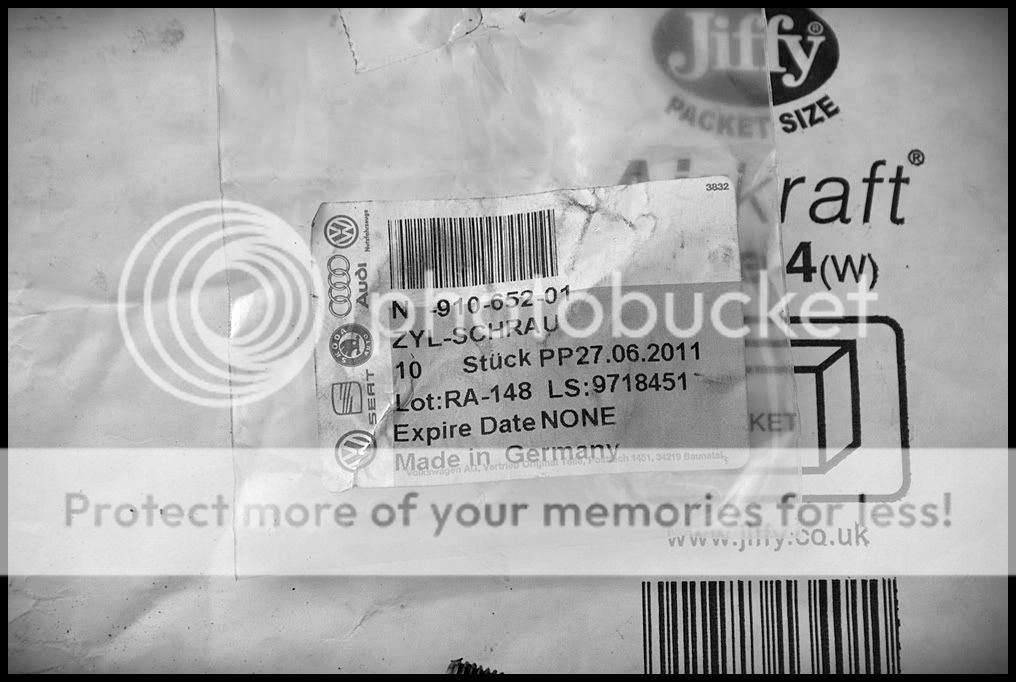

K03 hybrid turbo - Built by CR Turbo's (basically a ported K03 mated to a K04)

K04 MAF housing

Forge Actuator

Forge TIP

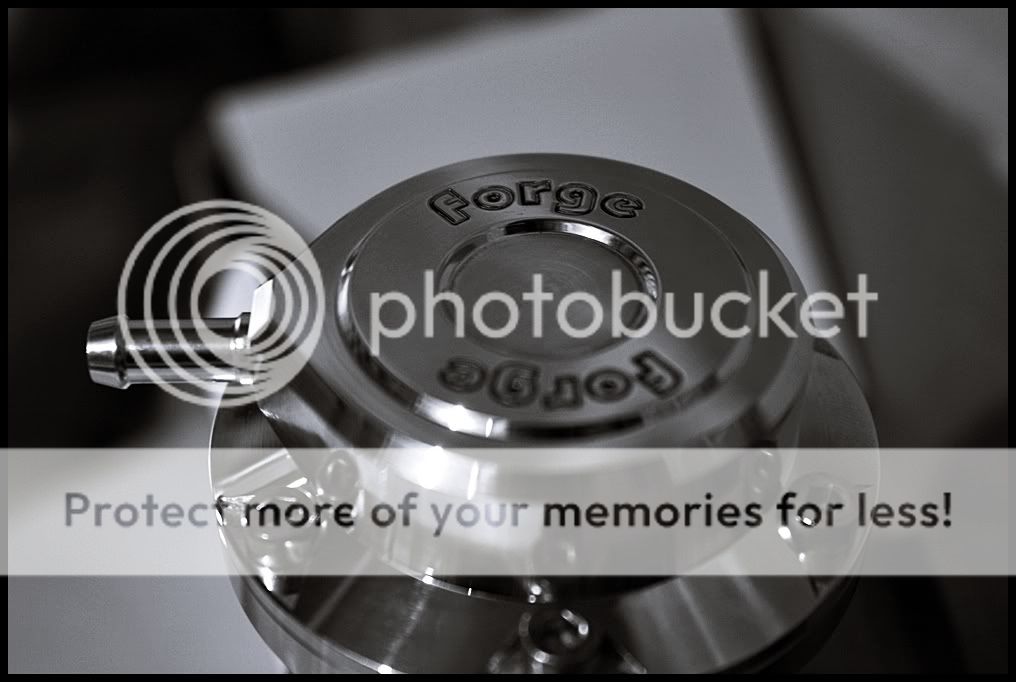

Forge DV

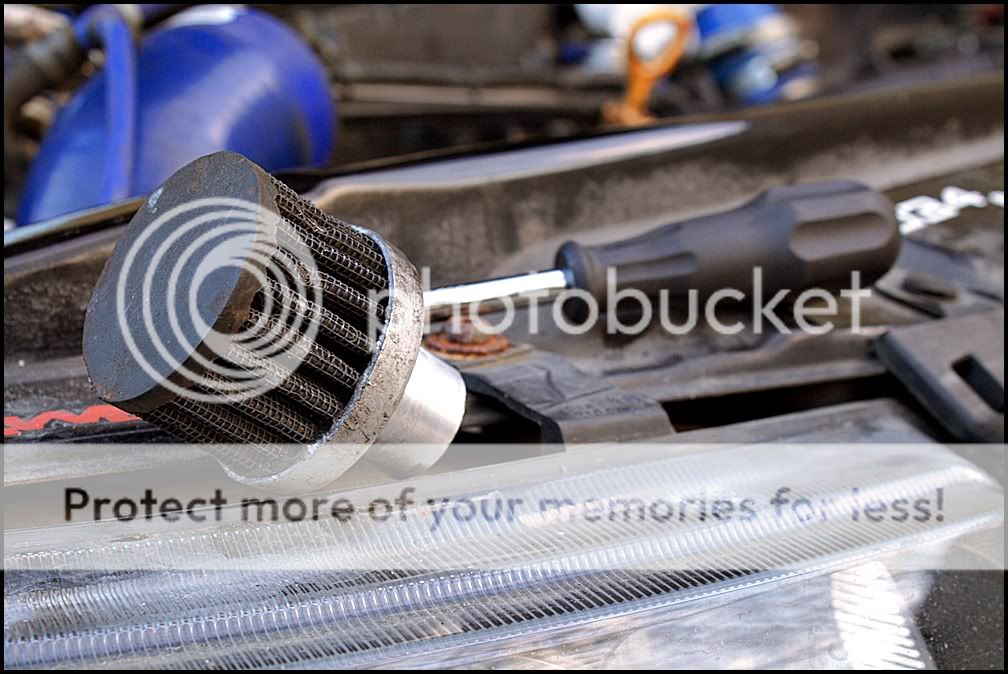

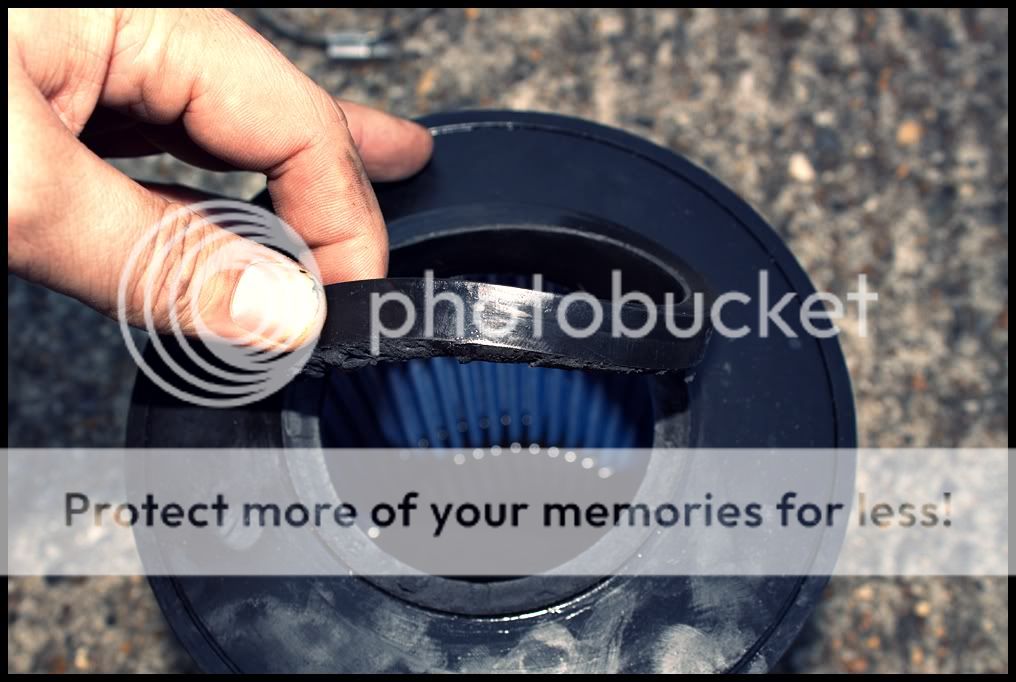

Green cone filter

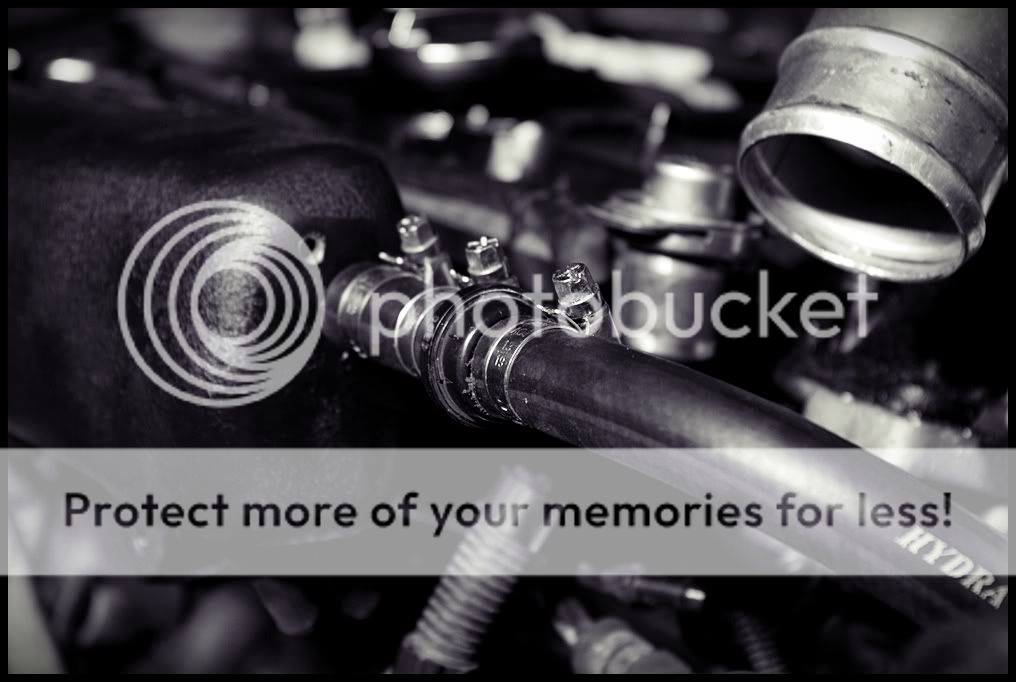

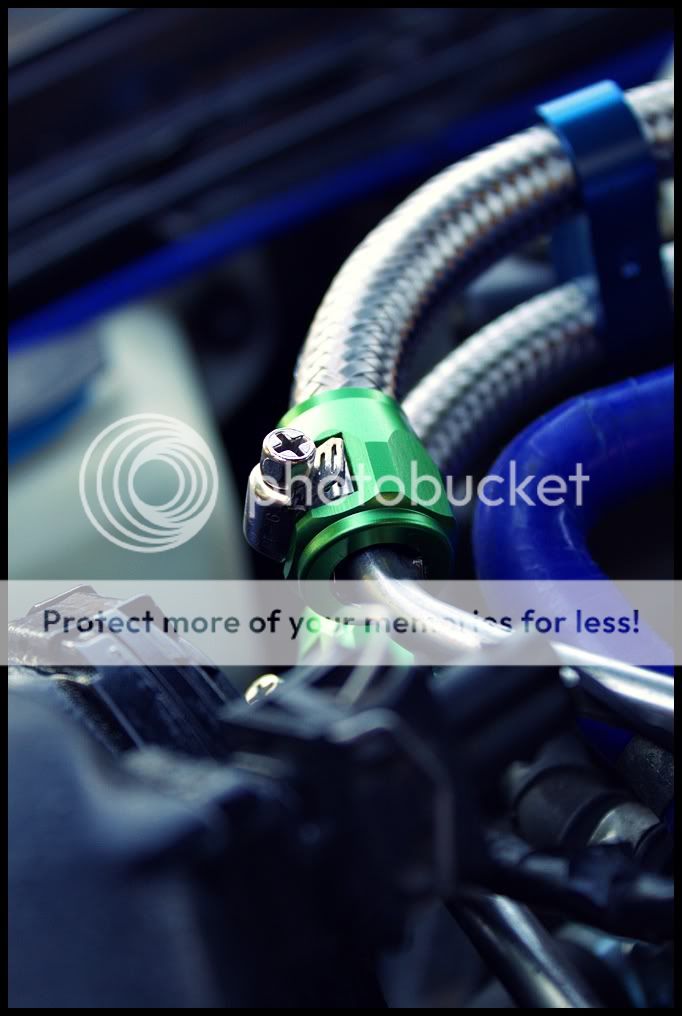

Braided fuel lines

Audi R8 petrol cap

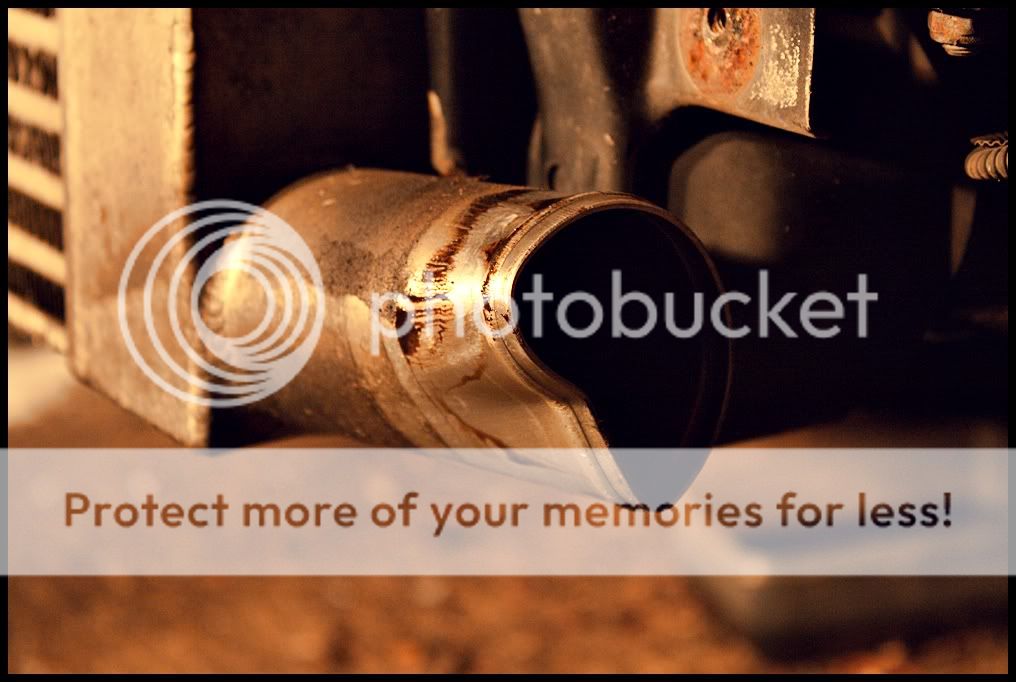

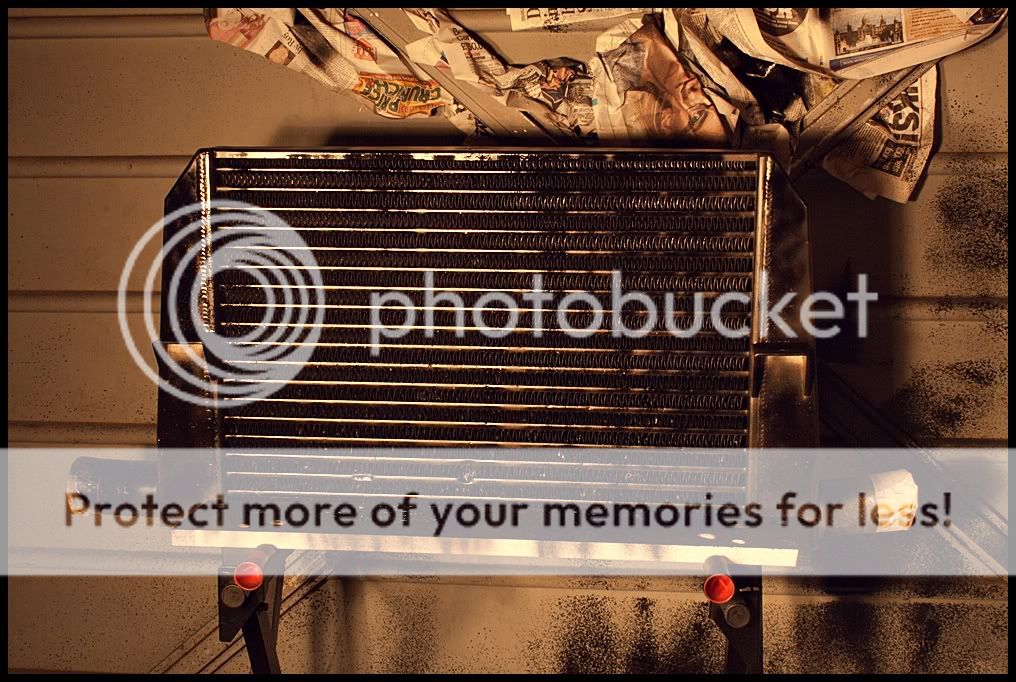

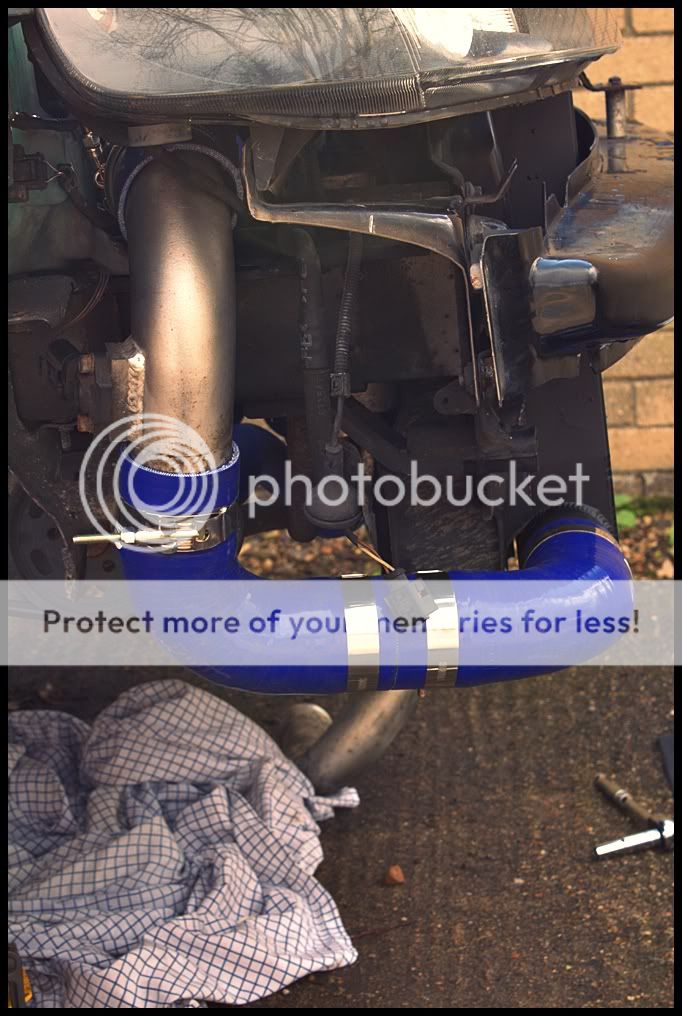

Pro Alloy FMIC

Blueflame oval turbo back exhaust

Decat

3" Downpipe

Stage 3 clutch

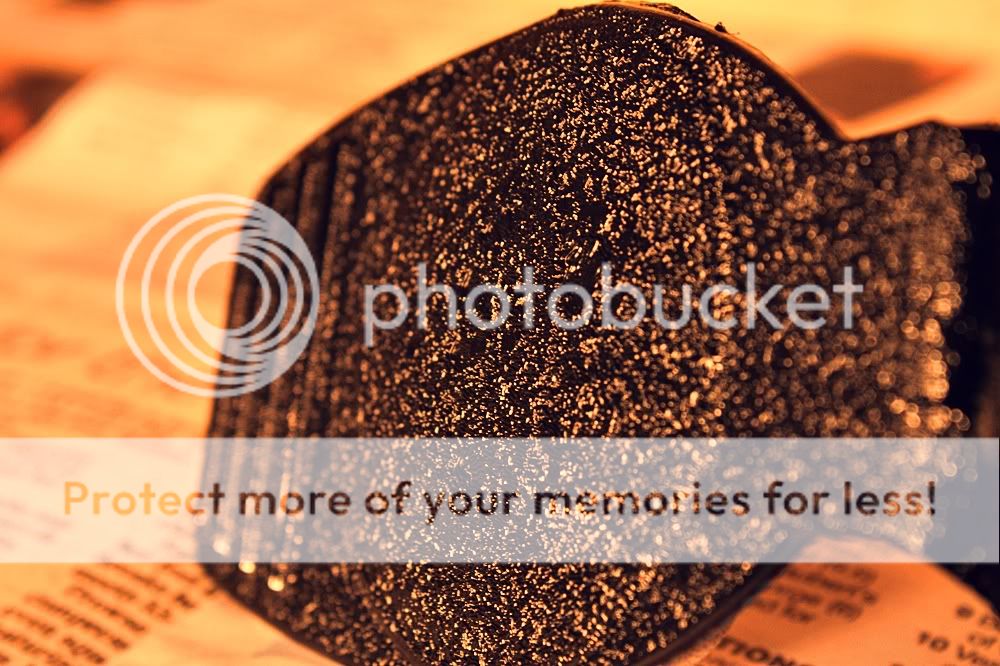

Carbon fibre coil pack cover

Hitachi bolt down coil packs

Crackle black intake manifold

Crackle black charge pipe

Forge coolant pipes

Satin black cam cover

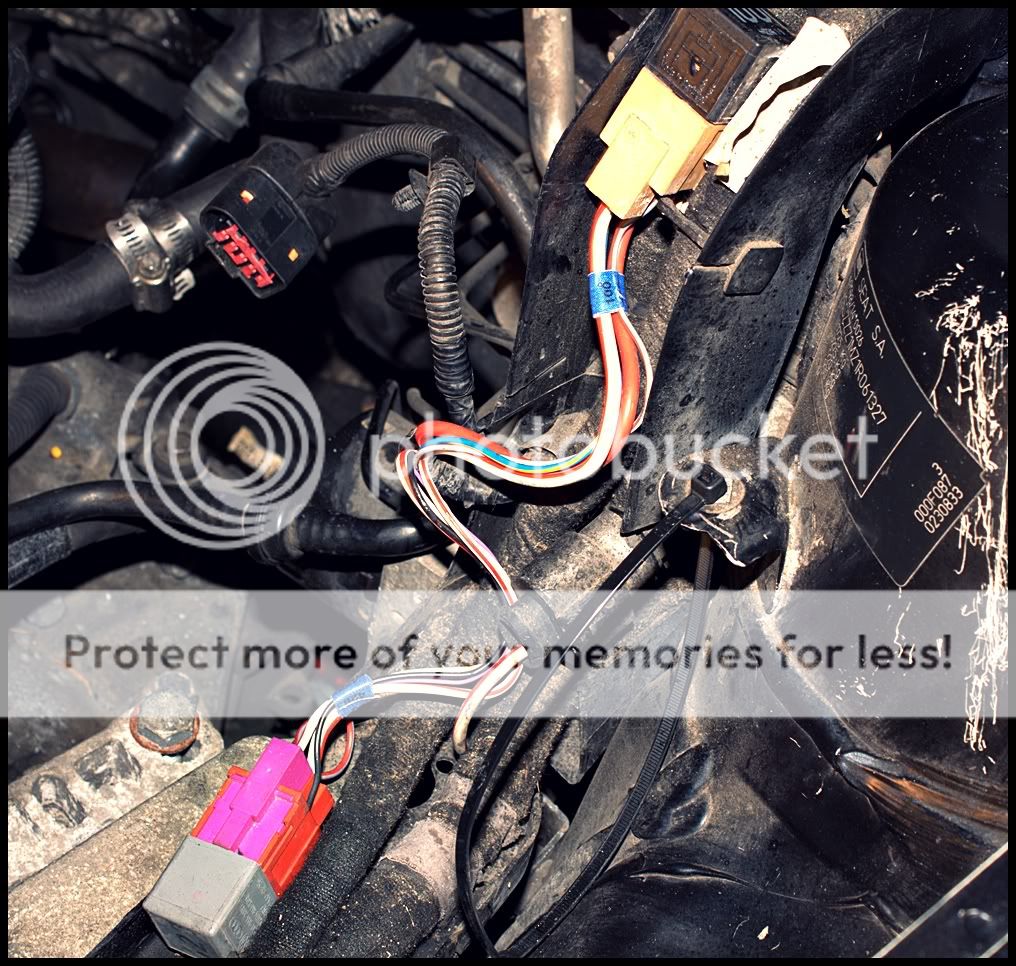

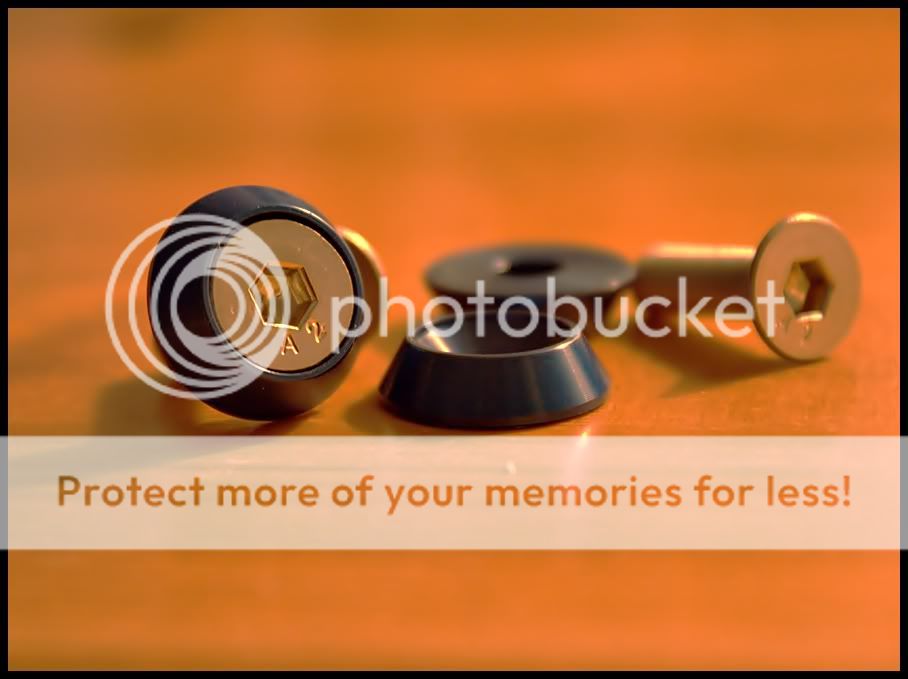

Various anodised connectors

Saikou Catch Can

N249 removal

Forge SAI blanking plate and SAI system removed

Carbon canister removed

Braided fuel hoses

Custom one off cold air filter

Supersize SFS TIP

Devils Own progressive water meth injection kit

Power

Mapped 291bhp & 287lbft

13.4 1/4 mile @ 108mph (GTI International at Shakespeare way 2013)

Handling

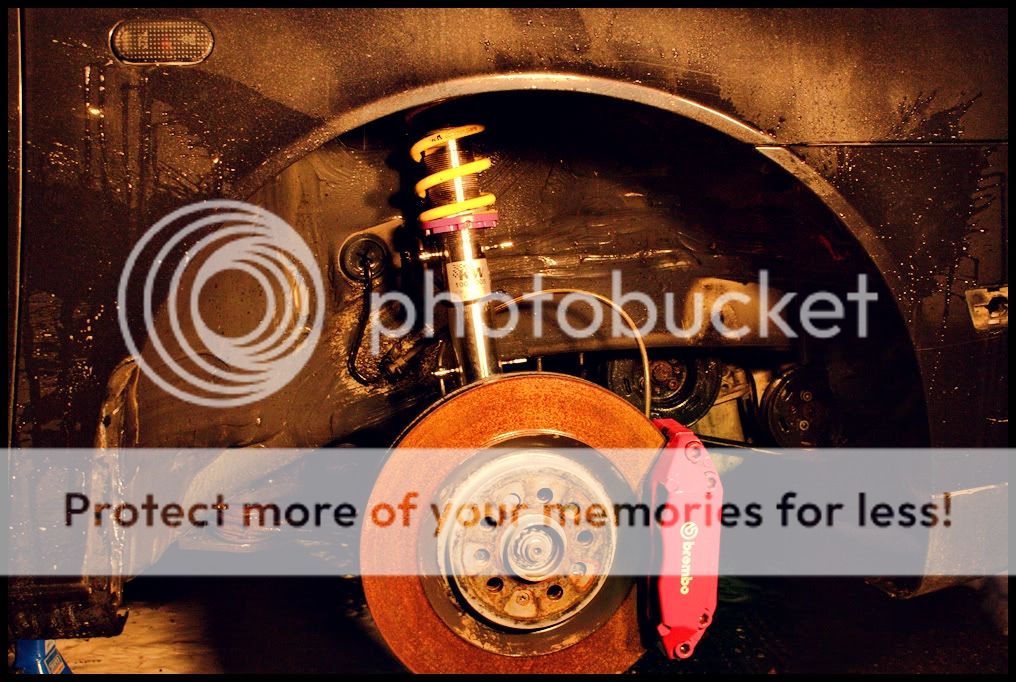

KW V1 coilovers

Neuspeed 25mm front ARB

Neuspeed 28mm rear ARB

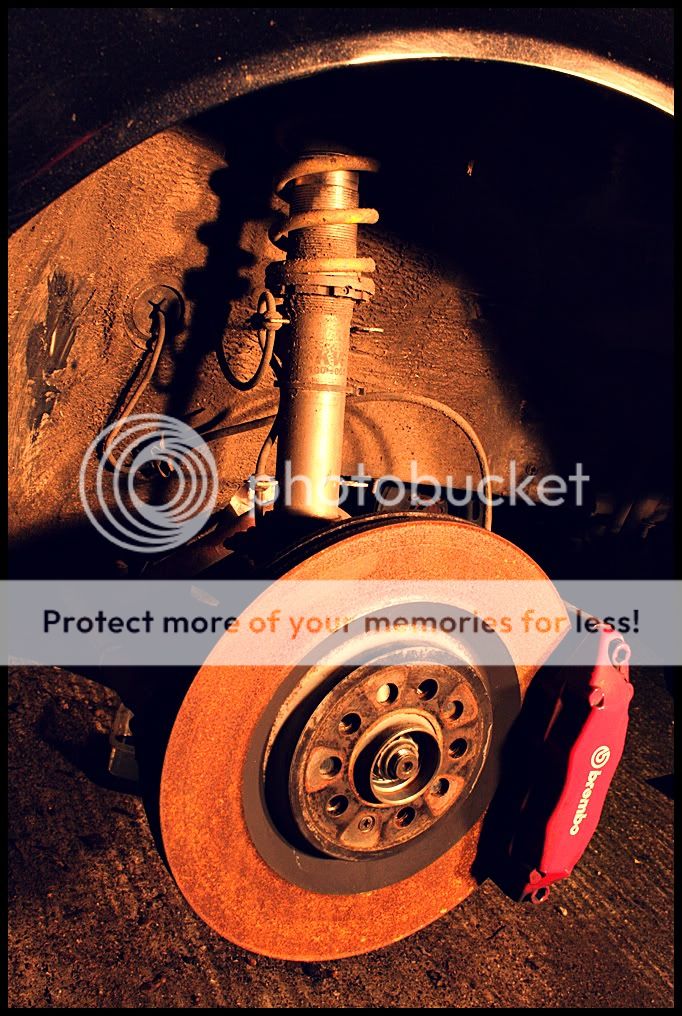

330mm Brembo's

Raceland Chassis strut brace

Styling

HID's 6000k

18" Oz Superleggera alloys

3m carbon wrapped bump strips

3m carbon wrapped spoiler

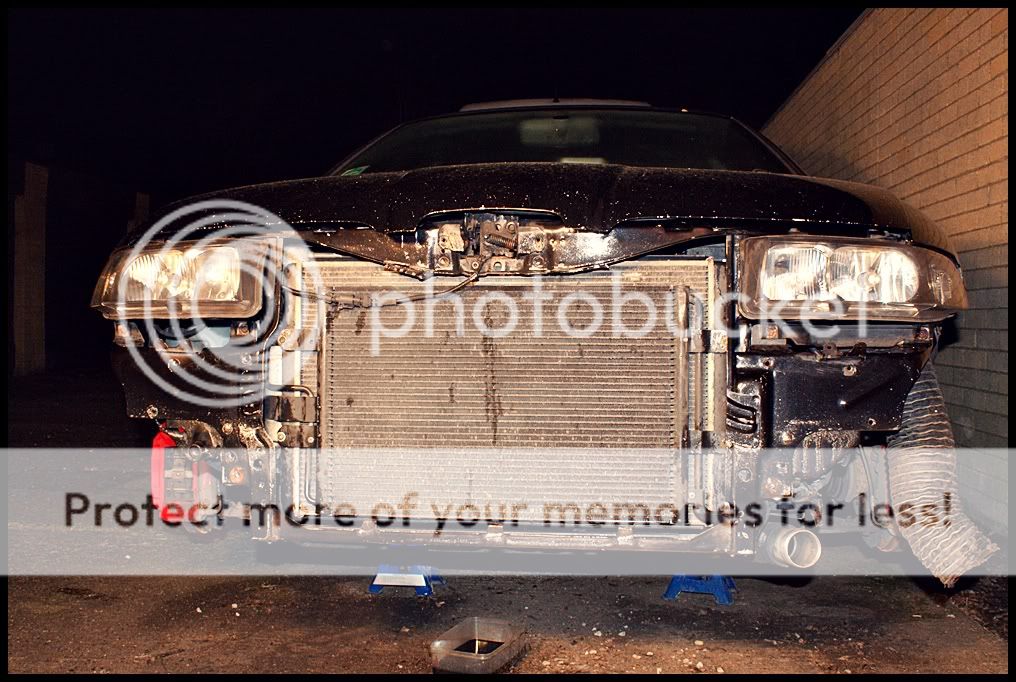

Front grill cut out to show the very large PA FMIC

One fog light removed for 100mm CAI

Front number plate cut out

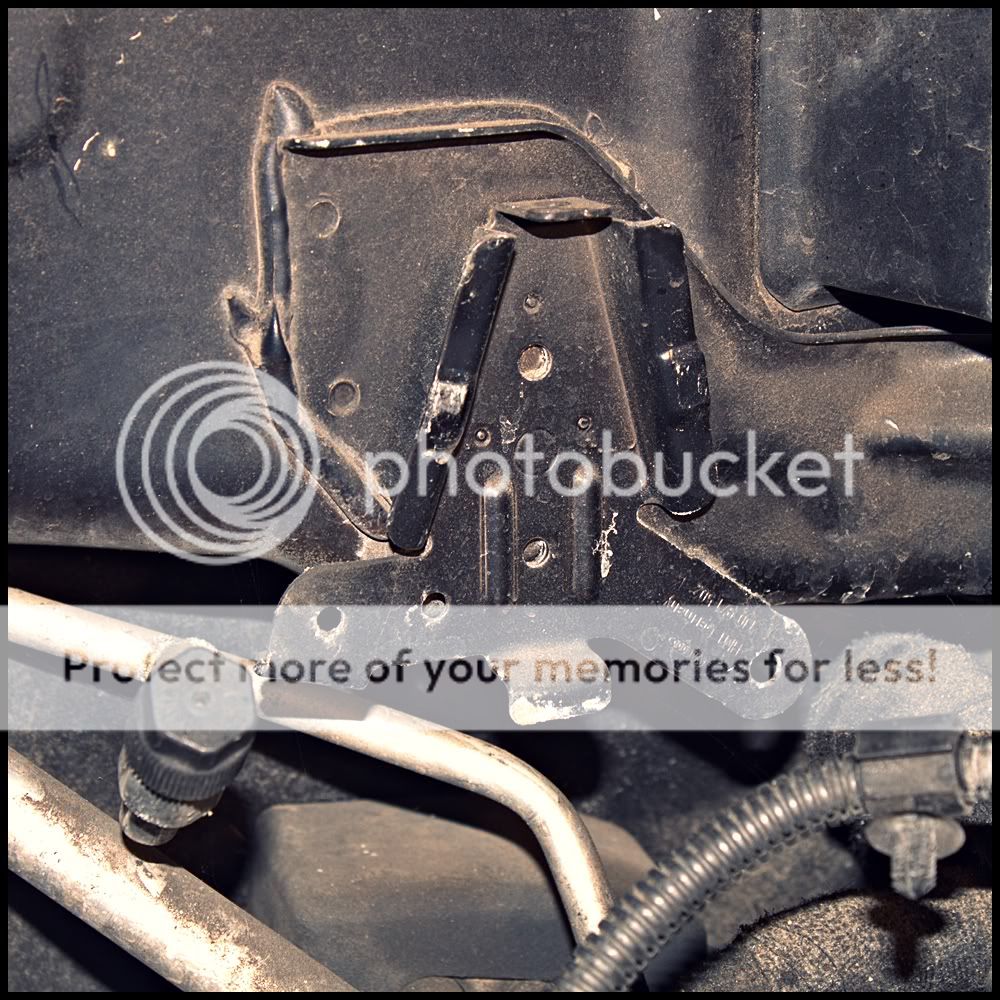

Crash bar drilled

Leon Cupra R rear spoiler

Interior

Auto gauge black faced boost gauge

Nomad single pillar pod

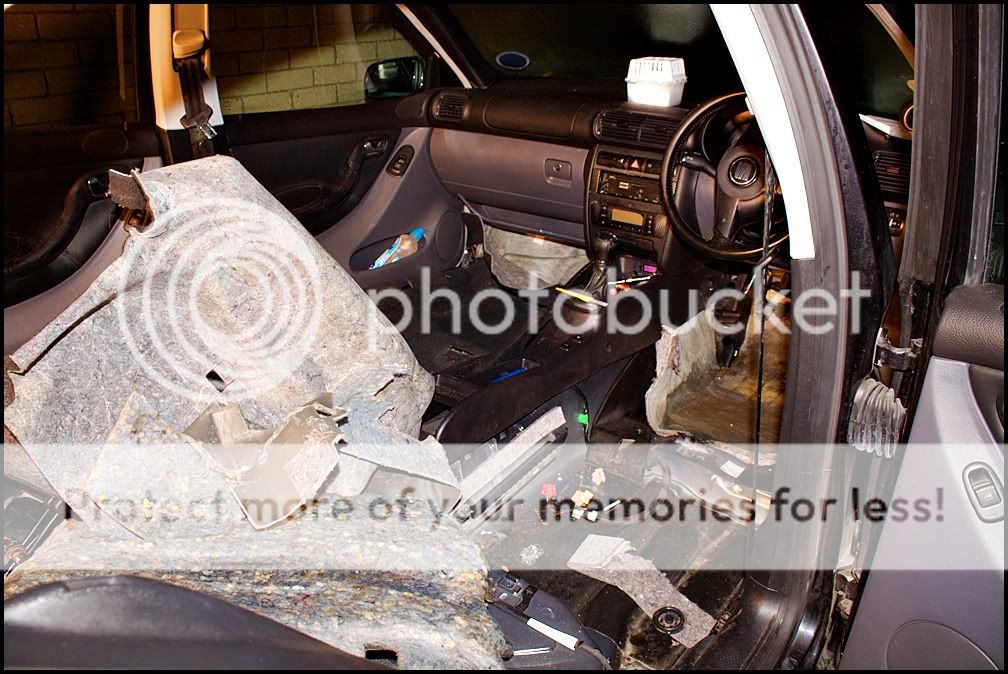

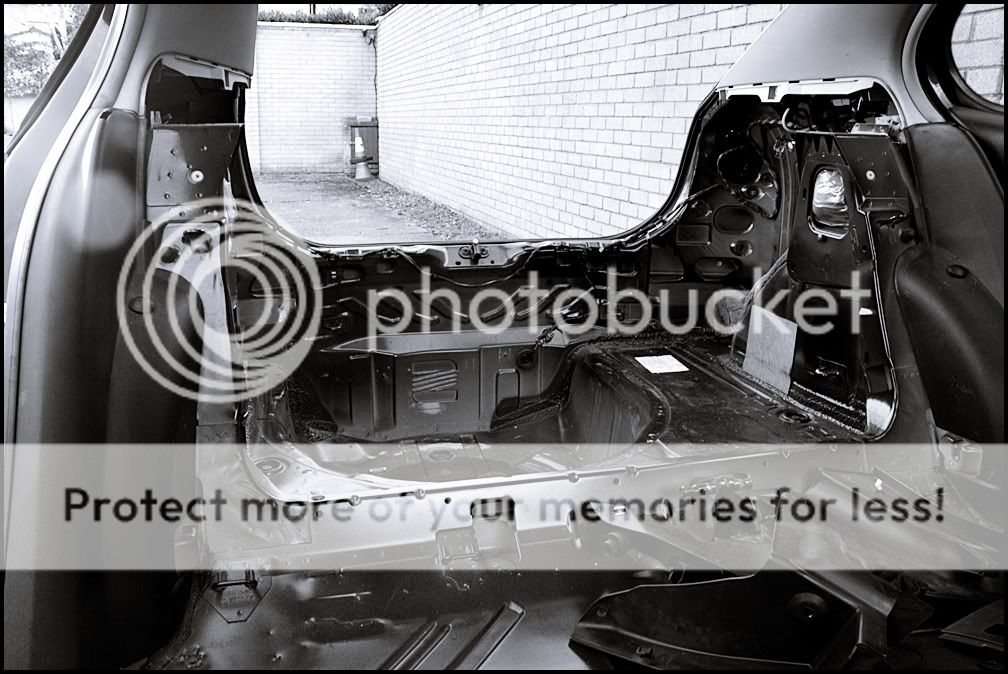

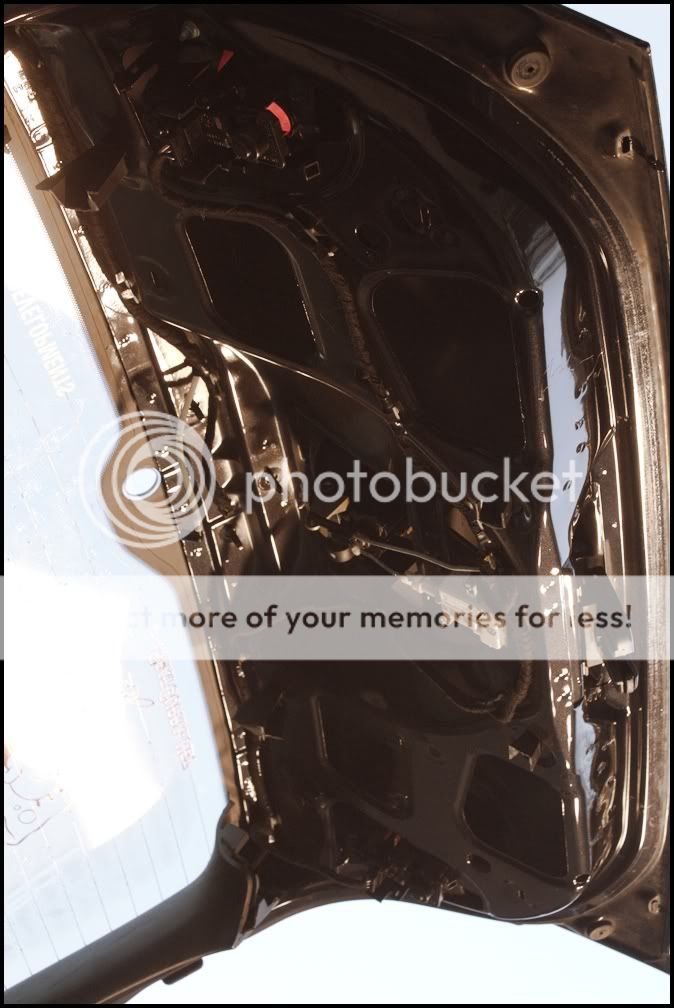

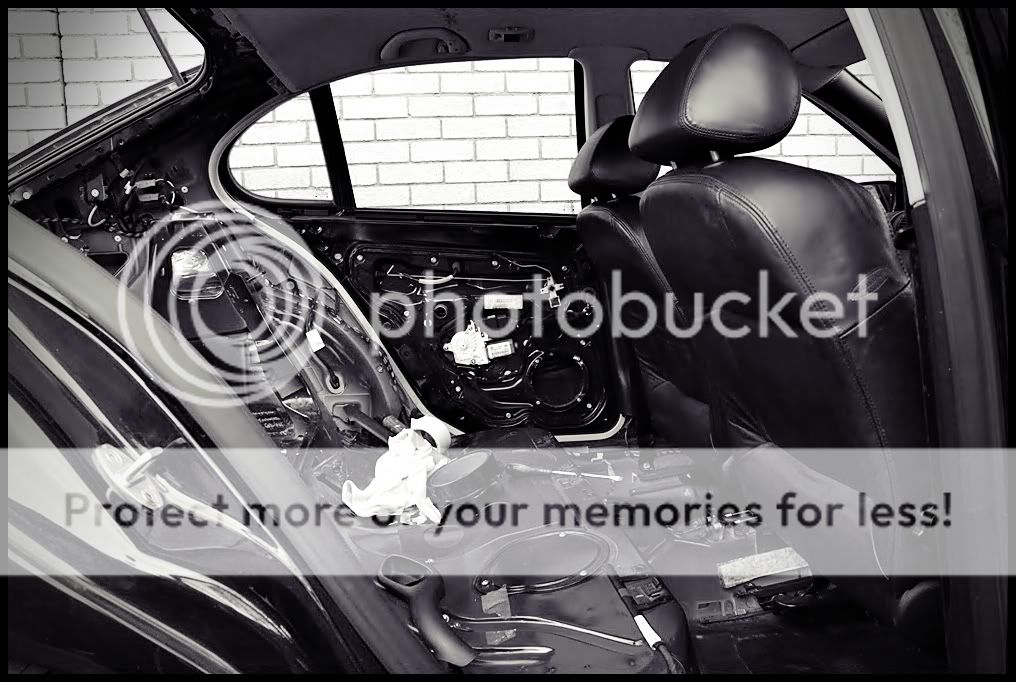

Fully stripped interior

Corbeau pro series fixed back bucket seat

3" 5 point harnesses

6 speed quick shift

Alloy racing battery tray

0 AWG battery wire

All sound deadening, carpets, plastics, roof lining, door cards and seats removed

The Story so far

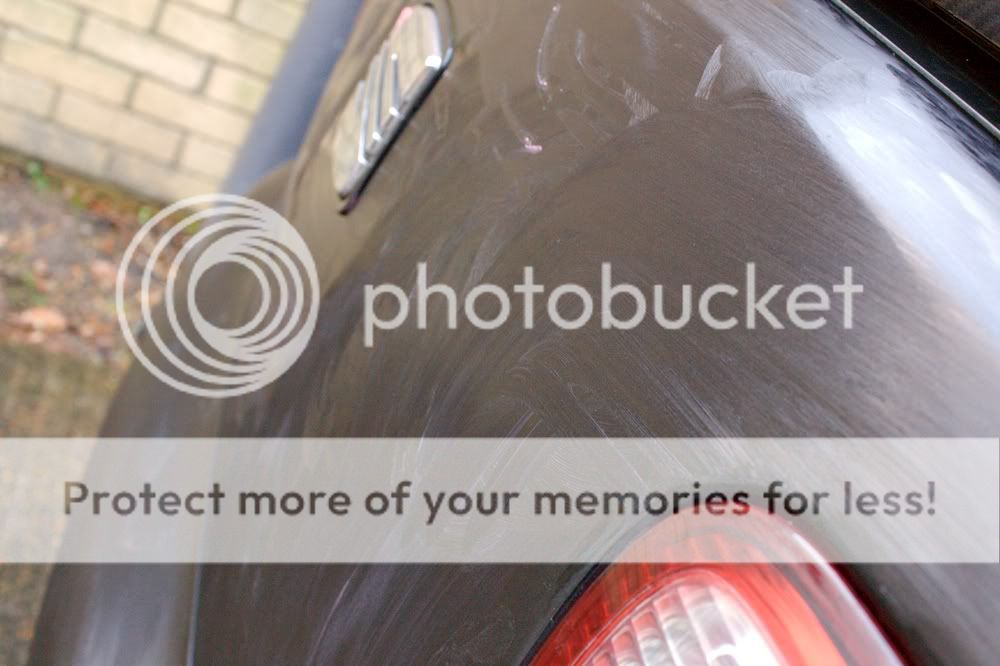

There are a few issues....

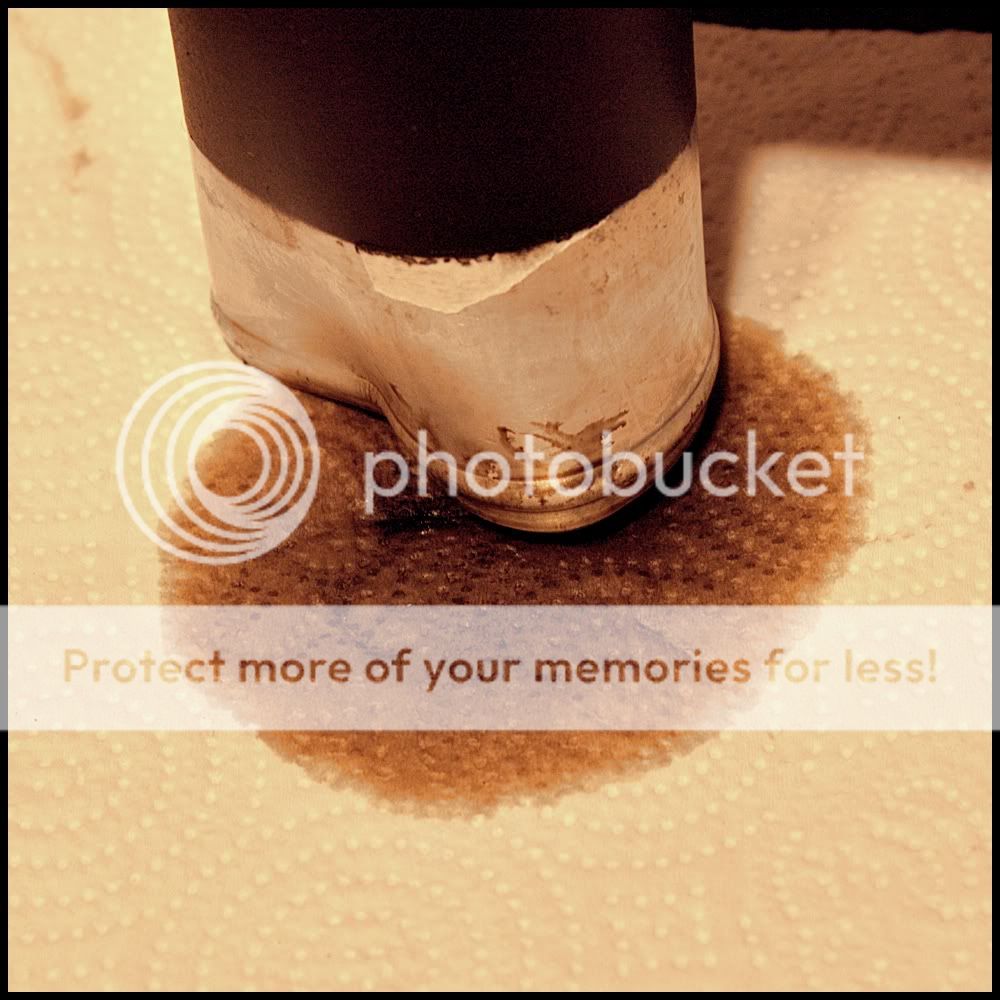

The turbo was making a sound when I bought her, and I was aware of this when I bought her, almost a squeeling sound on boost around 4000rpm - This has now been fixed with a new turbo

She is still in a bit of a mess at the mo,

Here is how she looked a while back

Standard spec:

2001 Black magic Seat Leon Cupra

Full black leather interior

Electric front seats

Electric folding mirrors

Electric windows all round

rain sensitive wipers

Auto dimming rear view mirror

Any other usual extra's

Modifications:

Engine

K03 hybrid turbo - Built by CR Turbo's (basically a ported K03 mated to a K04)

K04 MAF housing

Forge Actuator

Forge TIP

Forge DV

Green cone filter

Braided fuel lines

Audi R8 petrol cap

Pro Alloy FMIC

Blueflame oval turbo back exhaust

Decat

3" Downpipe

Stage 3 clutch

Carbon fibre coil pack cover

Hitachi bolt down coil packs

Crackle black intake manifold

Crackle black charge pipe

Forge coolant pipes

Satin black cam cover

Various anodised connectors

Saikou Catch Can

N249 removal

Forge SAI blanking plate and SAI system removed

Carbon canister removed

Braided fuel hoses

Custom one off cold air filter

Supersize SFS TIP

Devils Own progressive water meth injection kit

Power

Mapped 291bhp & 287lbft

13.4 1/4 mile @ 108mph (GTI International at Shakespeare way 2013)

Handling

KW V1 coilovers

Neuspeed 25mm front ARB

Neuspeed 28mm rear ARB

330mm Brembo's

Raceland Chassis strut brace

Styling

HID's 6000k

18" Oz Superleggera alloys

3m carbon wrapped bump strips

3m carbon wrapped spoiler

Front grill cut out to show the very large PA FMIC

One fog light removed for 100mm CAI

Front number plate cut out

Crash bar drilled

Leon Cupra R rear spoiler

Interior

Auto gauge black faced boost gauge

Nomad single pillar pod

Fully stripped interior

Corbeau pro series fixed back bucket seat

3" 5 point harnesses

6 speed quick shift

Alloy racing battery tray

0 AWG battery wire

All sound deadening, carpets, plastics, roof lining, door cards and seats removed

The Story so far

There are a few issues....

The turbo was making a sound when I bought her, and I was aware of this when I bought her, almost a squeeling sound on boost around 4000rpm - This has now been fixed with a new turbo

She is still in a bit of a mess at the mo,

Here is how she looked a while back

Last edited by a moderator: