Yeh that is impressive.

I once repaired a clio for a guy i worked with, he'd been driving along a main road, saw some mates in a petrol station, and probably in some kinda attempt to show off had tried to handbrake turn his way into the forecourt. Clearly was going far too fast, as the front understeered into a huge kerb and the rear followed.

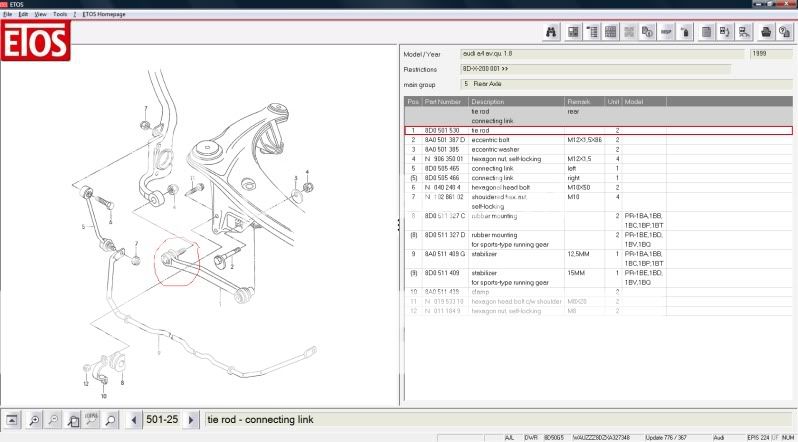

He dropped it off at the workshop i had, and i found that not only had he bent the subframe and the lower wishbone, but he'd sheared the knuckle clean thru below where the strut mounts, bent the shock, and bent the tie rod on the rack.

Put a new front end on it for him and test drove it round the block, which highlighted a bearing whine from the rear axle. The wheel looked streight, but we suggested he should get the car on an alignment machine and check if the axle is bent before we changed the bearing, plus the front end would need setup anyway. Instead of driving home and taking the car to an alignment shop like we suggested, he insisted on taking the car out to "cruise" that night, and after driving round (no doubt like a knob) for several hours, the bearing collapsed about half a mile from his house.

At which point he claimed we didnt fix the car properly and went elsewhere for the bearing replacement

Gleaming!!

Gleaming!!