TQS progress thread, From STD-Scroll-Eliminator.

- Thread starter Broken Byzan

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The AB 88 hoses are great still. Only reason they have been changed is because i have had larger dia pipes fitted. 63mm instead of the 51mm. To add more flowability with the larger TIP.

Some progress today.

I fitted the pedal box to the car with the extended mount for the new throttle pedal.

It resides under this lot

It requires removal of the servo master cylinder assy on RHD for certain. So i am going to need to bleed the clutch and brakes. On the plus side, she was due a fluid change....

While the loom was out i did the ICM delete with the B6 loom section 1JO 971 658 L, much cheaper than the repair looms you get.

I chose a loom from a 2000 Passat / A4 as it was sort of an in between model. Still had dumb coils, but no silly second Lambda probes or SAI etc.

The loom i used was 8D2 971 072 FQ. It plugs in directly to my 99 Facelift car loom with 99% the same connections.

This does come with a few problems like it's still a narrow band ECU, it is however still ME7 and fully flash-able and readable and tweak-able using Unisettings and the like .

I have added a connection for the engine light, from the orange plug to the blue dash plug pin 13.

On that same plug there is 2 black/blue wires, but the car side loom only has one, so i have bridged them to allow 12v .

The new loom expects to see the combined sump oil condition / temp sender . I checked and the wire that goes to the dash is the same for oil temp on both looms, so i just made the connection fit my old style sender.

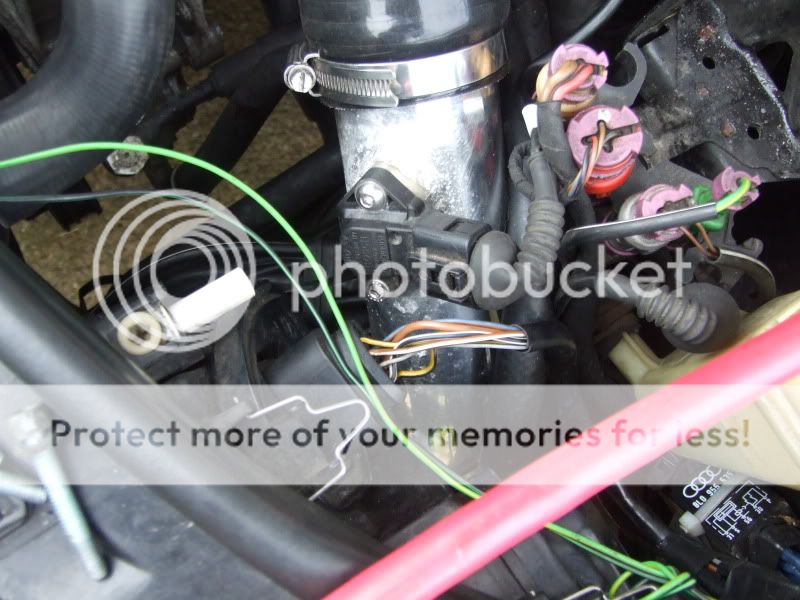

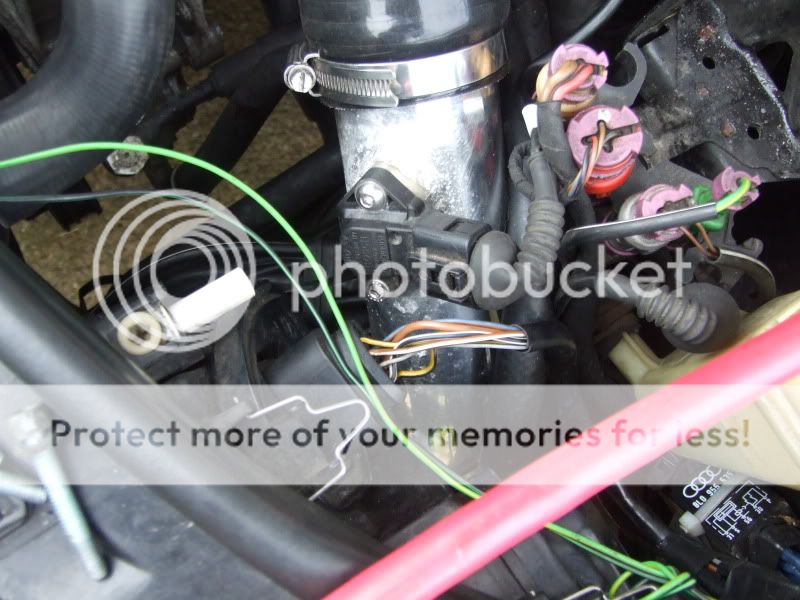

The MAF housing is different orientation to the old AEB/VR6 Combo i had previously.

The new style CTS was also required.

And a position welded to my FMIC pipes for the MAP sensor which would normally live on top of the OEM SMIC

May have added a boss for WMI while it was being done.

Throttle body needed to be changed to a DBW one, Not the studs, i found the normal TB bolts were too short so i made do with some studding and nuts i already had.

My chosen ECU is

4B0 906 018 AA Me7 ECU. Has so far read fine via Galleto and VAGcom

I had to add a N249 valve, even though i am not using it as such, the ECU needs to see the electrical connection.

The next hurdle is the Lambda sensor, even though both my car and the new setup are narrowband there is a difference of connection

For now i will splice it in, but will buy a new sensor, my old one has done 140K, so is probably passed its sell by date.

Now, here we are. Mostly together but..

She will not start, i can access ECU via Vagcom and it throws a code for faulty ECU relay 17925. I have a new one fitted but it seems that the 109 (1J0 906 381A) designation is incorrect despite the spades being correct.

I have ordered a 30 (165 906 381) for collection tomorrow, fingers crossed as i am too far into this to go backwards now.

Excuse the "snaps" lol

I fitted the pedal box to the car with the extended mount for the new throttle pedal.

It resides under this lot

It requires removal of the servo master cylinder assy on RHD for certain. So i am going to need to bleed the clutch and brakes. On the plus side, she was due a fluid change....

While the loom was out i did the ICM delete with the B6 loom section 1JO 971 658 L, much cheaper than the repair looms you get.

I chose a loom from a 2000 Passat / A4 as it was sort of an in between model. Still had dumb coils, but no silly second Lambda probes or SAI etc.

The loom i used was 8D2 971 072 FQ. It plugs in directly to my 99 Facelift car loom with 99% the same connections.

This does come with a few problems like it's still a narrow band ECU, it is however still ME7 and fully flash-able and readable and tweak-able using Unisettings and the like .

I have added a connection for the engine light, from the orange plug to the blue dash plug pin 13.

On that same plug there is 2 black/blue wires, but the car side loom only has one, so i have bridged them to allow 12v .

The new loom expects to see the combined sump oil condition / temp sender . I checked and the wire that goes to the dash is the same for oil temp on both looms, so i just made the connection fit my old style sender.

The MAF housing is different orientation to the old AEB/VR6 Combo i had previously.

The new style CTS was also required.

And a position welded to my FMIC pipes for the MAP sensor which would normally live on top of the OEM SMIC

May have added a boss for WMI while it was being done.

Throttle body needed to be changed to a DBW one, Not the studs, i found the normal TB bolts were too short so i made do with some studding and nuts i already had.

My chosen ECU is

4B0 906 018 AA Me7 ECU. Has so far read fine via Galleto and VAGcom

I had to add a N249 valve, even though i am not using it as such, the ECU needs to see the electrical connection.

The next hurdle is the Lambda sensor, even though both my car and the new setup are narrowband there is a difference of connection

For now i will splice it in, but will buy a new sensor, my old one has done 140K, so is probably passed its sell by date.

Now, here we are. Mostly together but..

She will not start, i can access ECU via Vagcom and it throws a code for faulty ECU relay 17925. I have a new one fitted but it seems that the 109 (1J0 906 381A) designation is incorrect despite the spades being correct.

I have ordered a 30 (165 906 381) for collection tomorrow, fingers crossed as i am too far into this to go backwards now.

Excuse the "snaps" lol

Last edited:

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

How the FIS?

Any good?

I too am interested mark... what did it set you back? and do you know if it works with the normal A4 (screen) cluster or just the s4

The 7.1 to 7.5 is a planned upgrade, maybe sooner than i thought due to a likely faulty ECU

I think i have blown something attempting to start it with the incorrect relay

17925/P1517/005399: Power Supply Relay for ECU (J271 or J363): Electrical Malfunction.

and

17987 - Throttle Actuator (J338): Adaptation Not Started P1579 - 35-00 - ...

Google suggests it the parts themselves check out, the ECU is U/S

I like to leave the solenoids plugged in as i have seen the pull down on resistors cause ECU and wiring issues that are hard to trace. I'll just fit them with short wires and leave them in the ECU box or code them out.

The FIS is great, It would be better if i could find someone to solder me a new screen into my dash though. What i can see of it is good,lol

I am assured it will work on pretty much any A4 with a Dis screen and stalks as std

I think i have blown something attempting to start it with the incorrect relay

17925/P1517/005399: Power Supply Relay for ECU (J271 or J363): Electrical Malfunction.

and

17987 - Throttle Actuator (J338): Adaptation Not Started P1579 - 35-00 - ...

Google suggests it the parts themselves check out, the ECU is U/S

I like to leave the solenoids plugged in as i have seen the pull down on resistors cause ECU and wiring issues that are hard to trace. I'll just fit them with short wires and leave them in the ECU box or code them out.

The FIS is great, It would be better if i could find someone to solder me a new screen into my dash though. What i can see of it is good,lol

I am assured it will work on pretty much any A4 with a Dis screen and stalks as std

Last edited:

- Joined

- Dec 12, 2003

- Messages

- 4,079

- Reaction score

- 93

- Points

- 48

- Location

- UK, London, SE

- Website

- hometown.aol.co.uk

Update.

SHE RUNS.......

No idea if she drives as i have no brakes as i broke the plastic retaining bracket that holds the servo rod to the brake peddle. I ordered one, but stupidly got LHD and now no where open till the morning

I had to add a wire from the white DBW plug and patch it to the relay to power up the throttle body / pedal. somehow missed that one.

The non start issue i had after that was a stupid rookie mistake and i had some wiring on the coil loom transposed.

So the fruits of my labour cannot be realised until wednesday because VW will need to order the plastic thing for delivery Wednesday no doubt.

To add insult to injury, the reliable Golf is using water like a good en, and i cannot see if going anywhere so as a result cannot drive that far either.

It never rains....

I will get a video / sound clip later.

She seems to idle and rev as she should but i am seeing a Signal too low signal from the MAF,, so i can assume it's either dead, or doesn't like the larger housing.

It may be this that's causing the ECU to pull 25% fuel out at idle, this has not changed even when i put a 3 bar FPR in to remove 15% fuel manually it's still pegged Flat out on lambda control.

It could be a consequence of the bad MAF or the map needs tweaking.

The worst is unisettings won't talk to it correctly so cannot remove some fuel via ECU base adjustments

SHE RUNS.......

No idea if she drives as i have no brakes as i broke the plastic retaining bracket that holds the servo rod to the brake peddle. I ordered one, but stupidly got LHD and now no where open till the morning

I had to add a wire from the white DBW plug and patch it to the relay to power up the throttle body / pedal. somehow missed that one.

The non start issue i had after that was a stupid rookie mistake and i had some wiring on the coil loom transposed.

So the fruits of my labour cannot be realised until wednesday because VW will need to order the plastic thing for delivery Wednesday no doubt.

To add insult to injury, the reliable Golf is using water like a good en, and i cannot see if going anywhere so as a result cannot drive that far either.

It never rains....

I will get a video / sound clip later.

She seems to idle and rev as she should but i am seeing a Signal too low signal from the MAF,, so i can assume it's either dead, or doesn't like the larger housing.

It may be this that's causing the ECU to pull 25% fuel out at idle, this has not changed even when i put a 3 bar FPR in to remove 15% fuel manually it's still pegged Flat out on lambda control.

It could be a consequence of the bad MAF or the map needs tweaking.

The worst is unisettings won't talk to it correctly so cannot remove some fuel via ECU base adjustments

- Joined

- Jan 5, 2006

- Messages

- 2,847

- Reaction score

- 188

- Points

- 63

- Location

- Somewhere in the Howardian Hills!

"just"? It only took you two years

I've been looking at some SAAB and Volvo turbos with a view to making some sort of poverty-spec turbo upgrade. Just need to wait patiently on ebay.

Aragorn.....Which SAAB turbo unit you after? I have a blown turbo (oil/water cooled) and a fully working (oil only cooled) unit, but they are from the early 900 B202 engines.

Dan

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

Good work.

Are you still using the LET injectors?

LET injectors on 3 bar are roughly the same as the standard APU injectors in terms of flow, so its understandable that the MAF housing upgrade is going to have the fuelling adaption off the scale.

It should also be adding fuel, not taking it out? Without any adaption, the bigger maf will cause the engine to run lean?

Its probably wise to stick the standard 2.5" maf on the car for now and make sure everythings working correctly, before going on to try to tune it?

Are you still using the LET injectors?

LET injectors on 3 bar are roughly the same as the standard APU injectors in terms of flow, so its understandable that the MAF housing upgrade is going to have the fuelling adaption off the scale.

It should also be adding fuel, not taking it out? Without any adaption, the bigger maf will cause the engine to run lean?

Its probably wise to stick the standard 2.5" maf on the car for now and make sure everythings working correctly, before going on to try to tune it?

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

Aragorn.....Which SAAB turbo unit you after? I have a blown turbo (oil/water cooled) and a fully working (oil only cooled) unit, but they are from the early 900 B202 engines.

Dan

If i was doing it, i'd have been wanting a TD04 from a 9000 Aero, however i've since discovered the way the bolts attach to the turbine housing would prove problematic, as aftermarket manifolds are typically threaded and expect the turbo to simply have thru holes, whereas the saab and volvo turbos both have studs fitted and require nuts on the manifold.

Good news!

How's HVAC controls and dash itself?

everything works bar the oil temp, but that's a simple wire swap. I have not tried the cruise yet as i have no brakes.

I have to be honest i haven't wired the load sense for the hvac to ECU, but it doesn't seem to mind at the mo

I have the 99 dash with analogue clock, not digital. That would require a different engine loom to match the later dash is all.

UPDATE.

Car drives, the daft broken plastic thing for the brakes was £2.51, whole car down, just for that...

Anyway, decided that because the MAF was showing a low signal so was obvisoulsy faulty as the wiring had been beeped through fine.

I located a new Bosch unit from ECP and used the AudiSRS discount code and got it for £60 for a genuine Bosch.

I bled the brakes and found that as soon as started the car would idle a min and cut out, and if revved to keep it running it "felt" it was running out of fuel, disconnected the new MAF and she idles fine, like she did on the old non working MAF

Anyone had this before?

Maf off the car drives fine, bar the engine light on, when connected the low signal fault goes and there are readings in vagcom but the car cuts out. Faulty MAF?

She sounds poorly due to the blowing exhaust, i think the wiggling around has seen it off.

So i need to buy some stainless tube sooner rather than later and get this fixed. BOOOOO

Car drives, the daft broken plastic thing for the brakes was £2.51, whole car down, just for that...

Anyway, decided that because the MAF was showing a low signal so was obvisoulsy faulty as the wiring had been beeped through fine.

I located a new Bosch unit from ECP and used the AudiSRS discount code and got it for £60 for a genuine Bosch.

I bled the brakes and found that as soon as started the car would idle a min and cut out, and if revved to keep it running it "felt" it was running out of fuel, disconnected the new MAF and she idles fine, like she did on the old non working MAF

Anyone had this before?

Maf off the car drives fine, bar the engine light on, when connected the low signal fault goes and there are readings in vagcom but the car cuts out. Faulty MAF?

She sounds poorly due to the blowing exhaust, i think the wiggling around has seen it off.

So i need to buy some stainless tube sooner rather than later and get this fixed. BOOOOO

Last edited:

Hey I need a new maf sensor pm the code and link for it please mark that's if it's the stock TQS sensor.

Bradderz, I have an almost new genuine one for a TQS if you need it?

Mine now uses a different sensor now

Mine now uses a different sensor now

Bradderz, I have an almost new genuine one for a TQS if you need it?

Mine now uses a different sensor now

PM me a price posted mate.

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

not checked today actually, probably DIS is ready 5MPG currently,lol

Learned values are nil, but as soon as it drops off cold start map, it pulls 25% out

Learned values are nil, but as soon as it drops off cold start map, it pulls 25% out

Last edited:

Update.

Dis MPG fixed, that was a wire swap.

The running issue was a dead newly supplied MAF unit, I borrowed one and tried it and it was perfect.

Now I was running on a STD ECU, but when the wiring was done i thought i'd change in the stage 1 ECU. Took it for a blast and quickly realised i had left the N75 connected.

I thought while it's connected i'd do a "test" run and log some stuff, All went well.

Lifted and continued to cruise, I pulled up to over take and my car picked up a dose of ScoobyItus...

Pulled up at Bills a few mins later still plonking around on 3, Upon checking the simple things it turned out i had Spark, Fuel, but no compression.

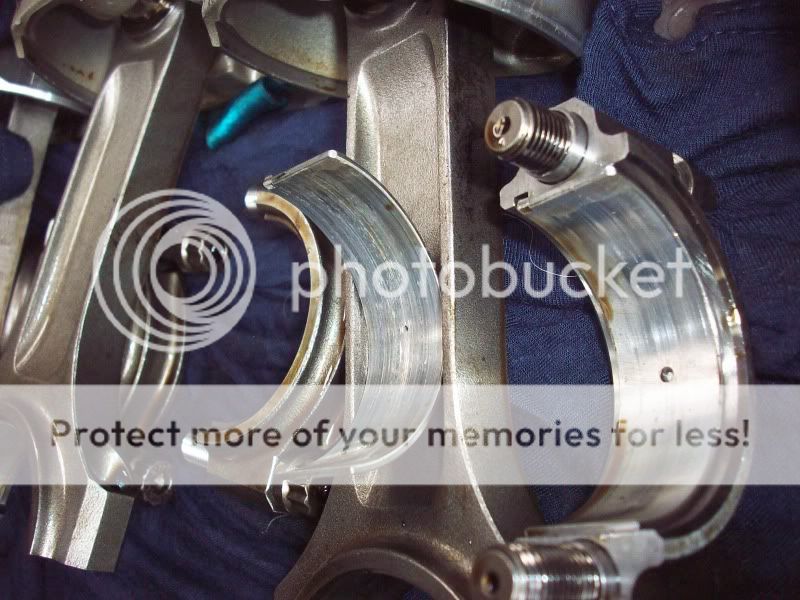

Heres why.

After seeing that it's pretty evident that the valve would have been cracked, but my stupidity running it lean/Untuned built the heat up. This caused a hot spot.

The pistons and bores seem to have survived, I wonder where the section of valve went.....

Ahhhhh .....................

So boys and girls, it just proves that even a quick blast on a badly tuned car can cause problems.

I will update tomorrow while i re build the head and work out what to do next.

Dis MPG fixed, that was a wire swap.

The running issue was a dead newly supplied MAF unit, I borrowed one and tried it and it was perfect.

Now I was running on a STD ECU, but when the wiring was done i thought i'd change in the stage 1 ECU. Took it for a blast and quickly realised i had left the N75 connected.

I thought while it's connected i'd do a "test" run and log some stuff, All went well.

Lifted and continued to cruise, I pulled up to over take and my car picked up a dose of ScoobyItus...

Pulled up at Bills a few mins later still plonking around on 3, Upon checking the simple things it turned out i had Spark, Fuel, but no compression.

Heres why.

After seeing that it's pretty evident that the valve would have been cracked, but my stupidity running it lean/Untuned built the heat up. This caused a hot spot.

The pistons and bores seem to have survived, I wonder where the section of valve went.....

Ahhhhh .....................

So boys and girls, it just proves that even a quick blast on a badly tuned car can cause problems.

I will update tomorrow while i re build the head and work out what to do next.

- Joined

- Nov 11, 2009

- Messages

- 10,099

- Reaction score

- 739

- Points

- 38

- Location

- west yorks

- Website

- www.stainless-engineering.co.uk

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

Update.

Dis MPG fixed, that was a wire swap.

The running issue was a dead newly supplied MAF unit, I borrowed one and tried it and it was perfect.

Now I was running on a STD ECU, but when the wiring was done i thought i'd change in the stage 1 ECU. Took it for a blast and quickly realised i had left the N75 connected.

I thought while it's connected i'd do a "test" run and log some stuff, All went well.

Lifted and continued to cruise, I pulled up to over take and my car picked up a dose of ScoobyItus...

Pulled up at Bills a few mins later still plonking around on 3, Upon checking the simple things it turned out i had Spark, Fuel, but no compression.

Heres why.

After seeing that it's pretty evident that the valve would have been cracked, but my stupidity running it lean/Untuned built the heat up. This caused a hot spot.

The pistons and bores seem to have survived, I wonder where the section of valve went.....

Ahhhhh .....................

So boys and girls, it just proves that even a quick blast on a badly tuned car can cause problems.

I will update tomorrow while i re build the head and work out what to do next.

Dude. Bummer.

I don't know what else to say.

I feel your pain.

Just when I thought you had hit the nail on the head with the build.

Hope you get everything sorted mate.

Hope you get everything sorted mate.

I have taken the head apart.. the valve has seen better days.

Sadly the seat is marked, and the throat of the port had melted valve stuck to it, i dremeled that off and was left with this un useable seat.

So that's off having a new seat fitted, fortunately that's only £40 which is cheaper than a new head.

I am aiming to clean and inspect all of the exhaust valves while she is apart to check for cracks and the likes.

While we are on the subject of cracks, the manifold has seen better days. This will have to be welded for now as i cannot afford to replace that just now

It's surprising how many parts make up the head assy.

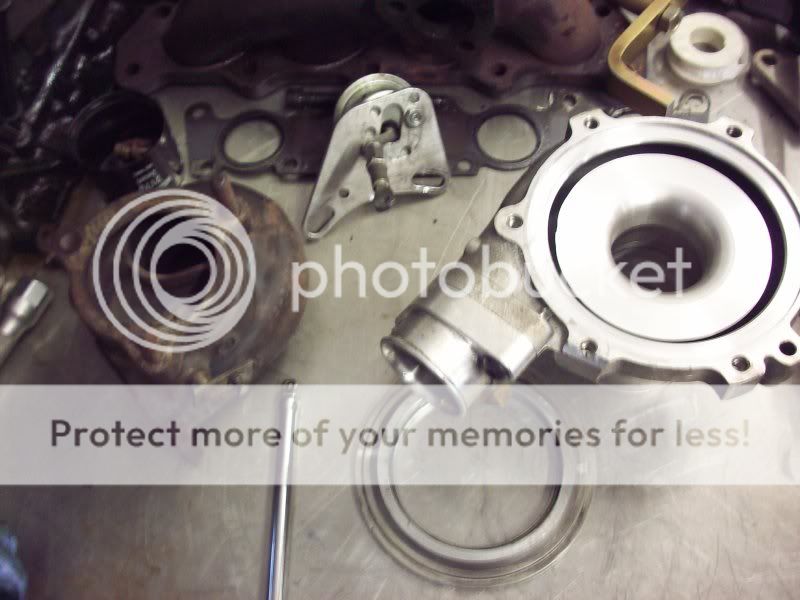

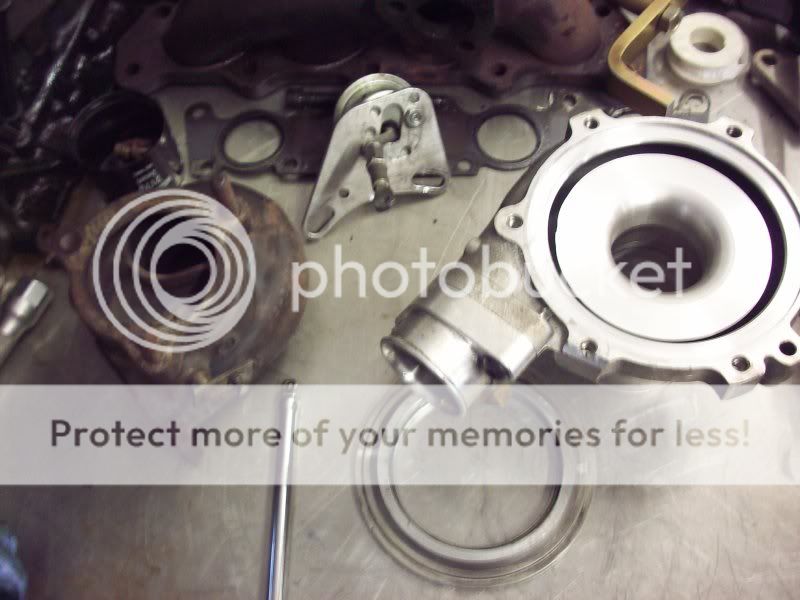

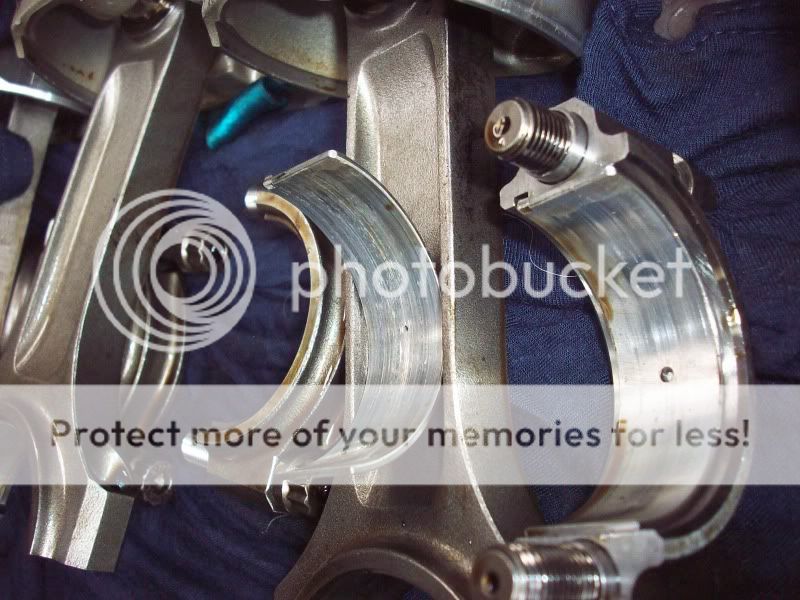

Old CHRA

Turbo in bits

And the new CHRA, It was ordered correctly but there is some issue that the part number makes it larger than the old one. Sadly i don't have both handy till sunday so will see whats what then. If it's wrong i am sure it can be fixed/replaced etc.

Sadly the seat is marked, and the throat of the port had melted valve stuck to it, i dremeled that off and was left with this un useable seat.

So that's off having a new seat fitted, fortunately that's only £40 which is cheaper than a new head.

I am aiming to clean and inspect all of the exhaust valves while she is apart to check for cracks and the likes.

While we are on the subject of cracks, the manifold has seen better days. This will have to be welded for now as i cannot afford to replace that just now

It's surprising how many parts make up the head assy.

Old CHRA

Turbo in bits

And the new CHRA, It was ordered correctly but there is some issue that the part number makes it larger than the old one. Sadly i don't have both handy till sunday so will see whats what then. If it's wrong i am sure it can be fixed/replaced etc.

Last edited:

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Mark,

I assume the A/S3 1.8T mani is different to the A4s cause the A3s engine is transverse?

Its only cause a couple of the A/S3 boys (Welly and Westy off the top of my head) might have some spare mani's.

Just a thought to save you from having a cracked/welded unit on.

I assume the A/S3 1.8T mani is different to the A4s cause the A3s engine is transverse?

Its only cause a couple of the A/S3 boys (Welly and Westy off the top of my head) might have some spare mani's.

Just a thought to save you from having a cracked/welded unit on.

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

yeh its positioned differently (turbo flange is infront of cyl 3 rather than 2) and the flange is also 180degrees out, so the turbo points the other way.

K04 (s3) manifold is different again, mounting the turbo even higher and further over.

K04 (s3) manifold is different again, mounting the turbo even higher and further over.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

yeh its positioned differently (turbo flange is infront of cyl 3 rather than 2) and the flange is also 180degrees out, so the turbo points the other way.

K04 (s3) manifold is different again, mounting the turbo even higher and further over.

O well the thought was there.

I'll get it welded for now and will get a new one when i can afford it in a month or so, priority is getting her working reliably as fast and as reasonably priced as possible.

Going to have a play tomorrow and see what we can get done.

Non of this would be possible without Bill @ Badger 5 or my friends and family for their support

Going to have a play tomorrow and see what we can get done.

Non of this would be possible without Bill @ Badger 5 or my friends and family for their support

NOt much progress.

A new clutch is needed as the old one cannot take it when she comes up on boost,so I am on actuator only ATM

1 bar actuator, but boost creep to 1.2 after 6k. Not sure how to fix that,

Just before the clutch was giving issues i was seeing 2 bar due to the creep, that's going to cause an issue, I am not sure how i am going to combat that just now.

I am seeing 186 GS at this 1.2 bar actuator, so not mega shabby.

A new clutch is needed as the old one cannot take it when she comes up on boost,so I am on actuator only ATM

1 bar actuator, but boost creep to 1.2 after 6k. Not sure how to fix that,

Just before the clutch was giving issues i was seeing 2 bar due to the creep, that's going to cause an issue, I am not sure how i am going to combat that just now.

I am seeing 186 GS at this 1.2 bar actuator, so not mega shabby.

I have attacked the **** end to stop the rear steering by polybushing the wishbones.

I have been chasing an annoying rattly noise and added to the fact its engine out to drop the sump it made sense to pull the engine to have a peak and change the clutch/ flywheel while i am in there.

I dropped the engine and box together with the aim of also nailing a 2wd box in for tuning purposes.

I am having to strip the old engine to have the rods and head from it.

The old pistons and rods pictured here comparing them to oem rods.

Found the cause of the noise.

Cylinder 3 shell is quite worn, the journal has picked up, good job I am changing the engine completely bar the head and rods.

Heat from the rattly shell has left a heat mark on the rod.

I am 99% the rod will be fine so it's going back in with new shells and rings

Note the notch and orientation of the shells, also this is an undamaged rod, you can see the difference

Piston rings compressed to go back in

New pump as a matter of course.

This is where i left here this evening.

Tomorrow the wastegate will hopefully be ported by Bill ready for the head to be refitted and turbo bolted on.

Then the SMFW and 240mm clutch and 2wd box, sounds simple huh.

I have been chasing an annoying rattly noise and added to the fact its engine out to drop the sump it made sense to pull the engine to have a peak and change the clutch/ flywheel while i am in there.

I dropped the engine and box together with the aim of also nailing a 2wd box in for tuning purposes.

I am having to strip the old engine to have the rods and head from it.

The old pistons and rods pictured here comparing them to oem rods.

Found the cause of the noise.

Cylinder 3 shell is quite worn, the journal has picked up, good job I am changing the engine completely bar the head and rods.

Heat from the rattly shell has left a heat mark on the rod.

I am 99% the rod will be fine so it's going back in with new shells and rings

Note the notch and orientation of the shells, also this is an undamaged rod, you can see the difference

Piston rings compressed to go back in

New pump as a matter of course.

This is where i left here this evening.

Tomorrow the wastegate will hopefully be ported by Bill ready for the head to be refitted and turbo bolted on.

Then the SMFW and 240mm clutch and 2wd box, sounds simple huh.

Not much progress but Bill checked the WG and we reset the preload once i had clocked the bracket to prevent it touching the ex manifold as it was very close. This left the adjustment too slack so i shortened the rod a few mm to allow more scope for adjustment if i ever need it

Currently cracking open at 1 bar

I came home and nailed the head on and the turbo for now, more tomorrow hoping to refit the engine Wednesday

Currently cracking open at 1 bar

I came home and nailed the head on and the turbo for now, more tomorrow hoping to refit the engine Wednesday

Lee Goodall

Registered User

Glad to see that you're making some good progress mate. Maybe one of us will get our car running properly at some point this year lol