- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

I think Audrey has lost boot again.

Same as what happened in Le-Man's, no power, foot flat nothing, struggles to get up hills.

I checked hoses and did the Mr Muscle cleaning but never made any difference.

I got VCDS out and checked for error codes.

I god this one,

1 Fault Found:

00575 - Intake Manifold Pressure

17-10 - Control Difference - Intermittent

I can only assume its the VNTs again. Since I was unable to split the turbo down last time, I could not give it a proper clean, just fill up with oven cleaner and hope its ok.

In the off chance its not or there is a better way around this, has any one got any ideas?

I don't really want to fork out for a new turbo but if its needed, then so be it. This turbo is 14 years old and 150k miles.

Any one got any thoughts on getting this one refurbished?

Same as what happened in Le-Man's, no power, foot flat nothing, struggles to get up hills.

I checked hoses and did the Mr Muscle cleaning but never made any difference.

I got VCDS out and checked for error codes.

I god this one,

1 Fault Found:

00575 - Intake Manifold Pressure

17-10 - Control Difference - Intermittent

I can only assume its the VNTs again. Since I was unable to split the turbo down last time, I could not give it a proper clean, just fill up with oven cleaner and hope its ok.

In the off chance its not or there is a better way around this, has any one got any ideas?

I don't really want to fork out for a new turbo but if its needed, then so be it. This turbo is 14 years old and 150k miles.

Any one got any thoughts on getting this one refurbished?

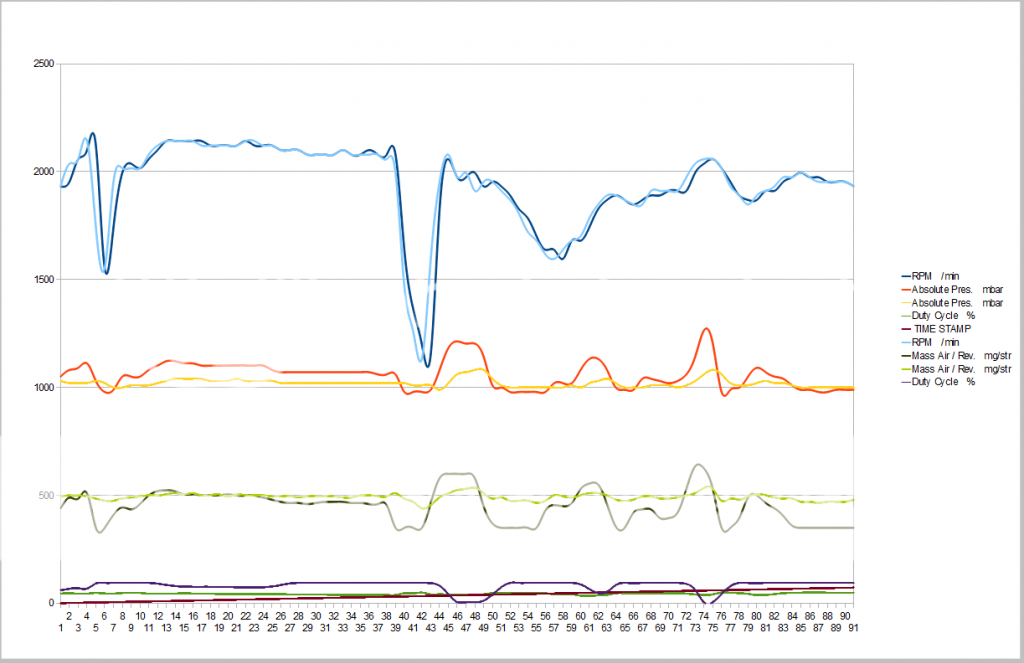

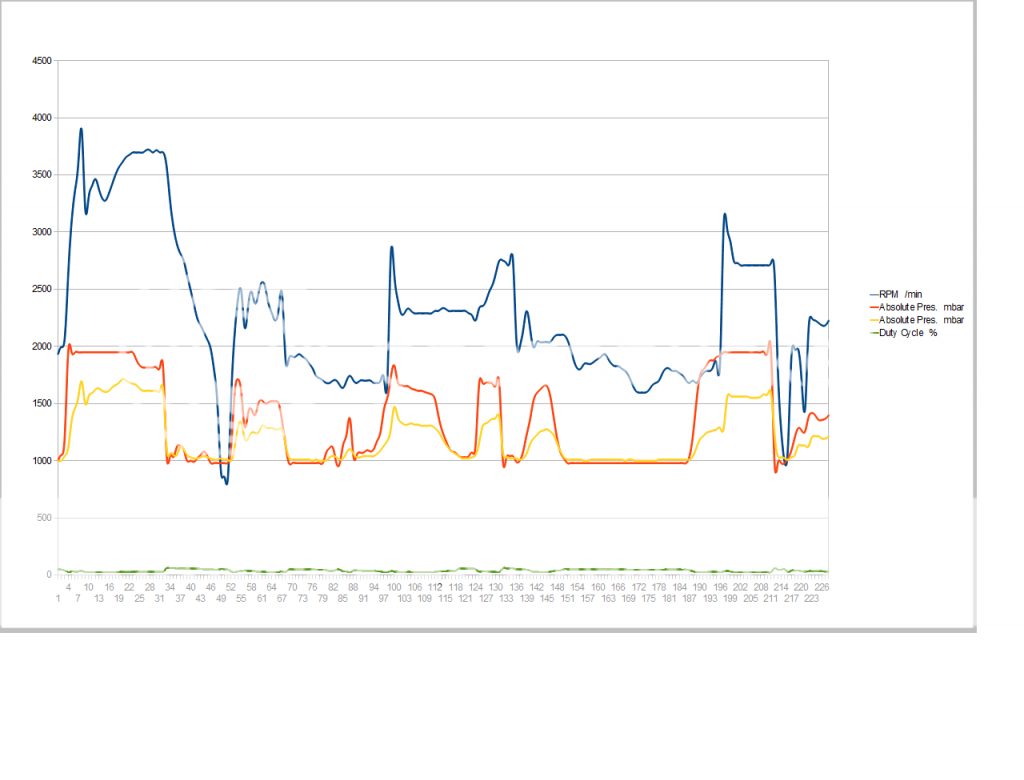

you can log a run and see what is going on with the N75 v Boost pressure like I did here

you can log a run and see what is going on with the N75 v Boost pressure like I did here