- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

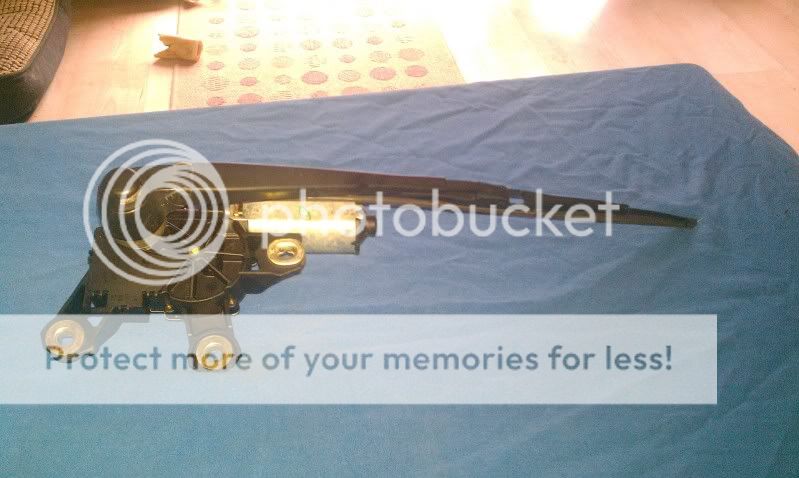

I felt like taking something apart so I dug out my old wiper motor and thought I'd strip it down, take pictures and share it with you lot.

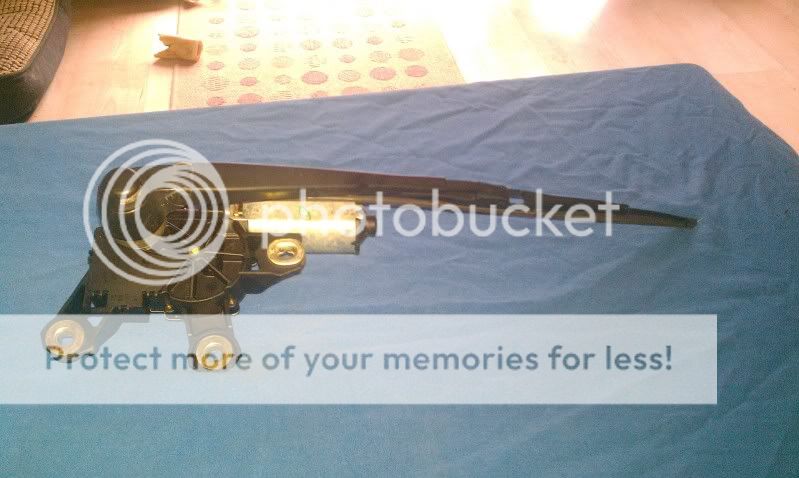

First, get the wiper motor (Arm is optional)

Remove wiper arm if still attached and remove the 6-8 screws thats holding the plate on.

This is what you'll see when you pull the backing off. That long metal tube is where the washer fluid goes through.

Next pull out the arm and wiper shaft.

Next is the main cog. You can see some of the contacts and a relay. This stops the motor when it done a full rotation of the cog, which is a full left to right wipe or is it right to left?

Closer pic for you

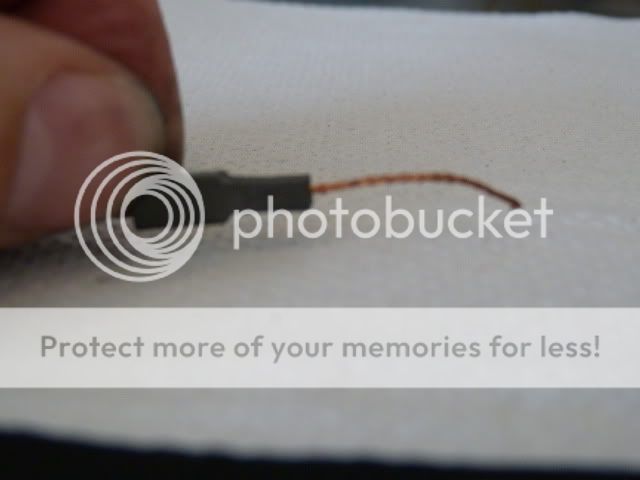

Next I took the motor out to check on the brushes and conections.

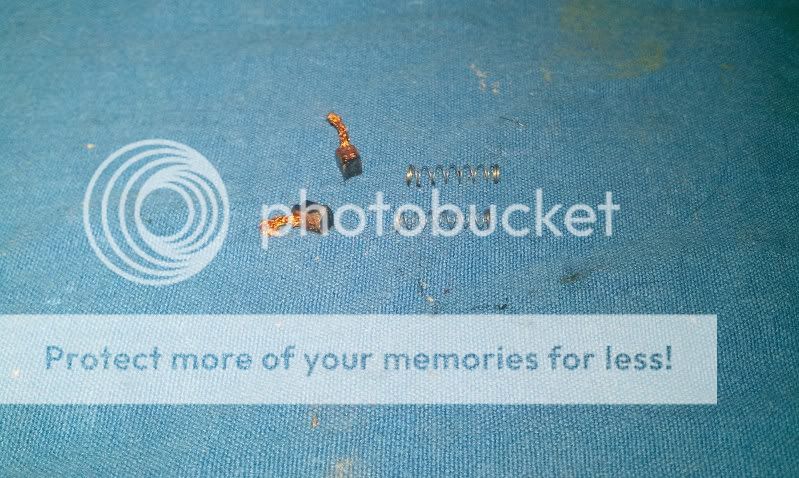

You can see the brushes are black and not very shiny.

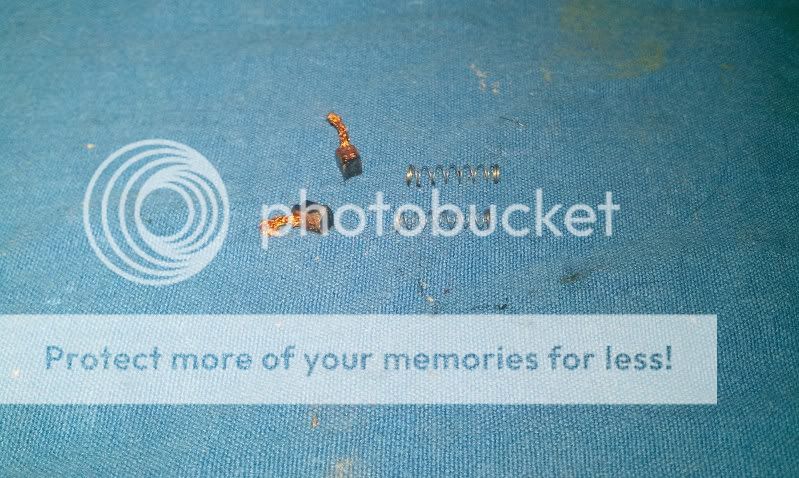

So I took them out to clean

They look very black and a little warn down. This might have been the cause of my sticking rear wiper.

With the motor off I pulled the shaft out the middle and gave it a good clean on the contact area for the brushes. Little bit of wear but nothing near as bad at the fan motor.

Thats it.

I stripped it all down, cleaned it all and put fresh grease in.

Ran 12v over the motor and it works and not sticking.

It looks like I got a fresh clean working motor.

I'm looking for new brushes for theses as I feel apart of the failure is due to the wear and carbon build up on the bushes.

If I find them I'll let you all know.

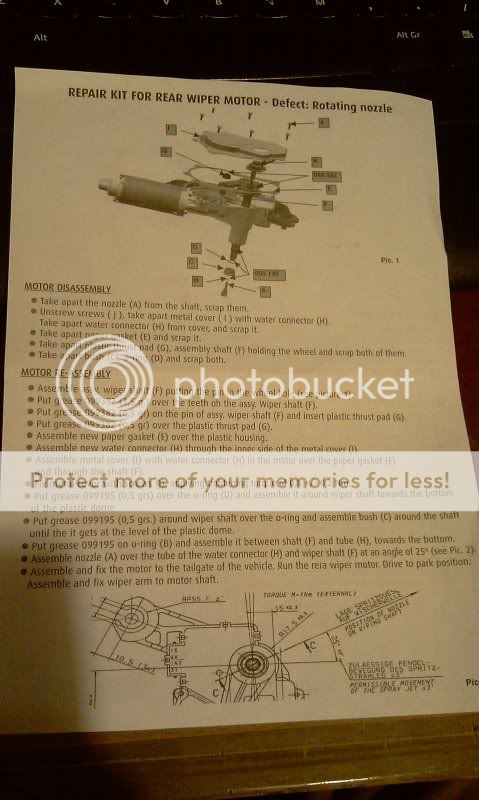

I have found theses as well, which is worth getting if your copper washer pipe has a hole in it.

http://www.ebay.co.uk/itm/320831382511

If any one is not confident in doing the work, I'm more than willing to undertake the work for you.

First, get the wiper motor (Arm is optional)

Remove wiper arm if still attached and remove the 6-8 screws thats holding the plate on.

This is what you'll see when you pull the backing off. That long metal tube is where the washer fluid goes through.

Next pull out the arm and wiper shaft.

Next is the main cog. You can see some of the contacts and a relay. This stops the motor when it done a full rotation of the cog, which is a full left to right wipe or is it right to left?

Closer pic for you

Next I took the motor out to check on the brushes and conections.

You can see the brushes are black and not very shiny.

So I took them out to clean

They look very black and a little warn down. This might have been the cause of my sticking rear wiper.

With the motor off I pulled the shaft out the middle and gave it a good clean on the contact area for the brushes. Little bit of wear but nothing near as bad at the fan motor.

Thats it.

I stripped it all down, cleaned it all and put fresh grease in.

Ran 12v over the motor and it works and not sticking.

It looks like I got a fresh clean working motor.

I'm looking for new brushes for theses as I feel apart of the failure is due to the wear and carbon build up on the bushes.

If I find them I'll let you all know.

I have found theses as well, which is worth getting if your copper washer pipe has a hole in it.

http://www.ebay.co.uk/itm/320831382511

If any one is not confident in doing the work, I'm more than willing to undertake the work for you.