Can anyone point me in the right direction as to what these abbreviations mean with you guys on here - things like "iirc" all the sentences read fine until you get to these points - then it turns into a foreign language - if there is an immoticon picture with it we all know what it says and means if not T.I.A.O.G. !!!! if you know what that means !!

A small project

- Thread starter ScottD3

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Can anyone point me in the right direction as to what these abbreviations mean with you guys on here - things like "iirc" all the sentences read fine until you get to these points - then it turns into a foreign language - if there is an immoticon picture with it we all know what it says and means if not T.I.A.O.G. !!!! if you know what that means !!

IIRC - If I Remember Correctly.

NineNails

Proud sponsor of the snack food industry

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

I'm still playing with this little project.

I recently built a test bench test rig so I can power the clocks up and run VCDS on them without having to fanny around in the car taking clocks out.

This way I can code my clocks and test the DIS when I replaced the screen.

Quick pic of my rig.

I've not got any further with the Rev counter, I've not had time to look at that but I will look at that once I got the oil sensor plumbed in.

Todays task to see if there is any Coding or Adaptation that I can do to code the clocks from a Manual B5 to a Auto B5 and part of me was hoping there was something in there to do with the revs.

The Coding was normal, nothing in there to help and I check Ross techs site and that did not help.

I then went on to Adaptation.

I was able to see a lot of different bits to code but some of them was unknowns.

Here is a list of what I was able to see.

02 - service reminder

03 - consmption correction

04 - language

09 - miles

18 - unknown

21 - keys

30 - tank sensor

32 - unknown

35 - speed threshold

40 - miles since service

41 - time since service

42 - minimum mileage to service

43 - maximum mileage to service

44 - max time to service

45 - oil quality

47 - Soot entry

48 - thermal load

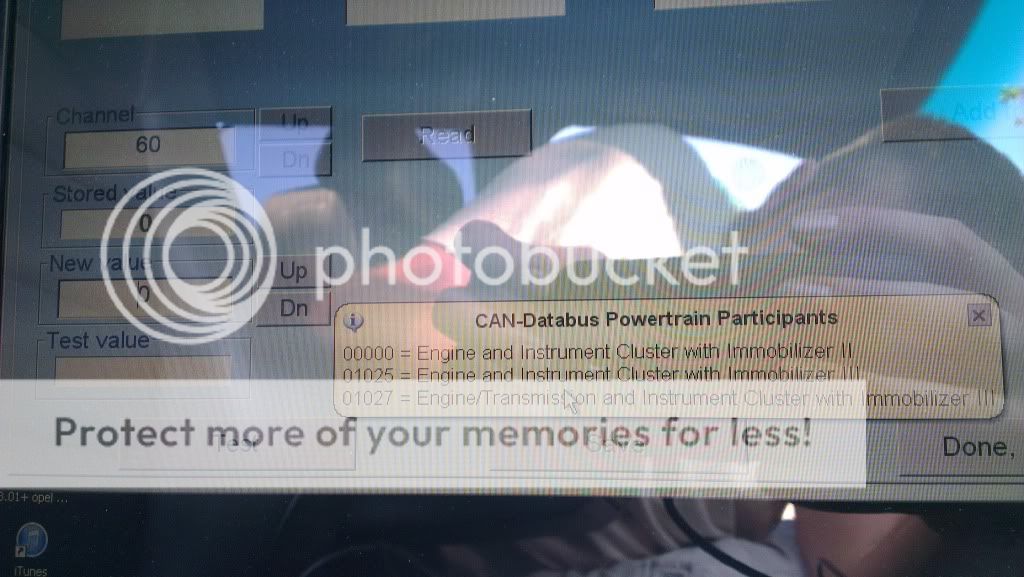

60 - can-databus powertrain participants

61 - unknown

62 - can-databue infotainment participants

18, 32 and 61 are unknown and showing zero values.

Does anyone know what these are?

I'm googling them now, so if I find anything I'll post it up.

I recently built a test bench test rig so I can power the clocks up and run VCDS on them without having to fanny around in the car taking clocks out.

This way I can code my clocks and test the DIS when I replaced the screen.

Quick pic of my rig.

I've not got any further with the Rev counter, I've not had time to look at that but I will look at that once I got the oil sensor plumbed in.

Todays task to see if there is any Coding or Adaptation that I can do to code the clocks from a Manual B5 to a Auto B5 and part of me was hoping there was something in there to do with the revs.

The Coding was normal, nothing in there to help and I check Ross techs site and that did not help.

I then went on to Adaptation.

I was able to see a lot of different bits to code but some of them was unknowns.

Here is a list of what I was able to see.

02 - service reminder

03 - consmption correction

04 - language

09 - miles

18 - unknown

21 - keys

30 - tank sensor

32 - unknown

35 - speed threshold

40 - miles since service

41 - time since service

42 - minimum mileage to service

43 - maximum mileage to service

44 - max time to service

45 - oil quality

47 - Soot entry

48 - thermal load

60 - can-databus powertrain participants

61 - unknown

62 - can-databue infotainment participants

18, 32 and 61 are unknown and showing zero values.

Does anyone know what these are?

I'm googling them now, so if I find anything I'll post it up.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Found a PDF from a S4 blog in the states.

If you got to page 70.

http://www.dj-sures.com/GraphicFile...uster, On Board Diagnostic from M.Y. 2000.pdf

18 - aux heater.

32 - Still unknown

61 - Can-databus comfort system

If you got to page 70.

http://www.dj-sures.com/GraphicFile...uster, On Board Diagnostic from M.Y. 2000.pdf

18 - aux heater.

32 - Still unknown

61 - Can-databus comfort system

- Joined

- May 25, 2012

- Messages

- 1,813

- Reaction score

- 200

- Points

- 63

- Location

- Hull, UK

- Website

- www.immotec.co.uk

Im very interested in doing something similar to you, however i was thinking about making a complete bench setup comprising of diagnostic port, ecu, clocks and key transponder loop. I was looking to start eeprom removal and reflashing as a hobby, not just with vag but all cars/ecu types. Just means raiding scrapyards and ebay for unmatched ecu/clusters, with the intention to resell a coded set later.

accepting free donations of unmatched /broken/immobiliser failed clusters and ecus lol.

BTW my a6 cluster is foobar... needs an lcd when your free to play with it

accepting free donations of unmatched /broken/immobiliser failed clusters and ecus lol.

BTW my a6 cluster is foobar... needs an lcd when your free to play with it

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Im very interested in doing something similar to you, however i was thinking about making a complete bench setup comprising of diagnostic port, ecu, clocks and key transponder loop. I was looking to start eeprom removal and reflashing as a hobby, not just with vag but all cars/ecu types. Just means raiding scrapyards and ebay for unmatched ecu/clusters, with the intention to resell a coded set later.

accepting free donations of unmatched /broken/immobiliser failed clusters and ecus lol.

BTW my a6 cluster is foobar... needs an lcd when your free to play with it

You can't has all the broken the clusters. We'll share them.

The loom you want should be easier enough with the wiring diagram and some spare plugs from a scrapyard.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

My new sump with oil sensor hole turned up at the dealers this week, that should be getting fitted next month along with a oil service.

Once the oil sensor is wired in I should be able to run with the clocks with no annoying beeps.

With clocks wired in with no annoying beeps due to the oil sensor, I'll be able to run with them while I sort out the rev counter issue and the lack of Automatic gear box messages on the DIS.

Has anyone out there got a Facelift B5 with a Automatic box?

I wonder if its possible to copy your coding for my clocks?

I've kind of hit a bit of a dead end with the rev counters. I've ran out of ideas.

Anyone got any ideas of something I could try or take a look at?

Once the oil sensor is wired in I should be able to run with the clocks with no annoying beeps.

With clocks wired in with no annoying beeps due to the oil sensor, I'll be able to run with them while I sort out the rev counter issue and the lack of Automatic gear box messages on the DIS.

Has anyone out there got a Facelift B5 with a Automatic box?

I wonder if its possible to copy your coding for my clocks?

I've kind of hit a bit of a dead end with the rev counters. I've ran out of ideas.

Anyone got any ideas of something I could try or take a look at?

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Picked up my new sump and fitted the oil level sensor.

This should be fitted next month along with a new oil pump and filter.

Hopefully this will solve a oil leak I've been experiencing plus quiet the oil warning on the facelift clocks.

More I look back at this project and look at the time and effort I've put in, the more I question if its really worth it and should I just give up..........I just hope it is.

Next on my lift while I'm waiting for the sump to be fitted.

I need to buy a new DIS screen and get that working in the clock, run the oil sensor cables, run the cables for the doors, boot and bonnet opening on the DIS, run the canbus cables for the satnav to clocks and still need to work out why the rev counter is not working and how to change the clocks to display the Automatic transmission information. I've checked VCDS on the facelift clocks and can't find anything.

I went through all the adaptations in post #124 and could not see any thing.

Hopefully with the oil sensor wired in I can run the clocks with no beeping every 15mins saying there is no oil and I can play about with the clocks in the car and other parts of the car.

My fear with the rev counter is that it wont work cause its expecting a signal via canbus or other cable from the newer ECU.

If that's the case I'll have to take a look at getting a newer AFN ECU and see if I can wire it in. I hope I don't have to do this.

This should be fitted next month along with a new oil pump and filter.

Hopefully this will solve a oil leak I've been experiencing plus quiet the oil warning on the facelift clocks.

More I look back at this project and look at the time and effort I've put in, the more I question if its really worth it and should I just give up..........I just hope it is.

Next on my lift while I'm waiting for the sump to be fitted.

I need to buy a new DIS screen and get that working in the clock, run the oil sensor cables, run the cables for the doors, boot and bonnet opening on the DIS, run the canbus cables for the satnav to clocks and still need to work out why the rev counter is not working and how to change the clocks to display the Automatic transmission information. I've checked VCDS on the facelift clocks and can't find anything.

I went through all the adaptations in post #124 and could not see any thing.

Hopefully with the oil sensor wired in I can run the clocks with no beeping every 15mins saying there is no oil and I can play about with the clocks in the car and other parts of the car.

My fear with the rev counter is that it wont work cause its expecting a signal via canbus or other cable from the newer ECU.

If that's the case I'll have to take a look at getting a newer AFN ECU and see if I can wire it in. I hope I don't have to do this.

jbh

TDi lover

- Joined

- Jan 3, 2010

- Messages

- 1,410

- Reaction score

- 171

- Points

- 63

- Location

- Slamannan/ Central Scotland

- Website

- www.retrobmw.co.uk

hats off to you Scott. just read through this and well to be honest I wouldnt even have attempted it.

I would be happy just to get a set of clocks in with the oil temp and volt meter

I would be happy just to get a set of clocks in with the oil temp and volt meter

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

hats off to you Scott. just read through this and well to be honest I wouldnt even have attempted it.

I would be happy just to get a set of clocks in with the oil temp and volt meter

Don't you have oil temp or volt meter on yours?

I just hope its worth it.

jbh

TDi lover

- Joined

- Jan 3, 2010

- Messages

- 1,410

- Reaction score

- 171

- Points

- 63

- Location

- Slamannan/ Central Scotland

- Website

- www.retrobmw.co.uk

no I was surprised at it not having them TBH with it being the 110 I expected it to have themDon't you have oil temp or volt meter on yours?

I just hope its worth it.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

The sump and oil level sensor has been fitted.

http://www.audi-sport.net/vb/a4-s4-...-new-sump-pump-pick-up-filter-sensor-oil.html

Time to check the pin outs on the oil level sensor and connect them to my clock loom and then plug the clocks in.

Jobs done............Ish.

If the oil level sensor works and oil temp worked properly, I still need to sort out the revs and convert the clocks to Auto from manual.

I will look a bit more into that at some point.

http://www.audi-sport.net/vb/a4-s4-...-new-sump-pump-pick-up-filter-sensor-oil.html

Time to check the pin outs on the oil level sensor and connect them to my clock loom and then plug the clocks in.

Jobs done............Ish.

If the oil level sensor works and oil temp worked properly, I still need to sort out the revs and convert the clocks to Auto from manual.

I will look a bit more into that at some point.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

They would look really nice in a petrol.

jbh

TDi lover

- Joined

- Jan 3, 2010

- Messages

- 1,410

- Reaction score

- 171

- Points

- 63

- Location

- Slamannan/ Central Scotland

- Website

- www.retrobmw.co.uk

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

I'm hoping to spend a couple of hours tonight playing about with the clocks again, in preparation for all being well with the oil level sensor I've been checking the wiring again which had raised a few questions and a small mistake on my part.

First off, the loom I used to make my PFL to FL clock loom was from a manual and as such it was missing the Auto gear selector cable. I'm not sure how this will change the clocks but I'm interested to see what it does.

It appears to come from the Red 20 pin connector on the PFL loom/clock and goes to the green plug on the FL loom/clock.

Red 6 - Selector lever position indicator to Green 31 - Selector lever position indicator

I'll wire that up as well.

If all goes well with the above I hope to wire up the RNS-d and get some navigation on the DIS as well.

Looking at the pinouts there is multiple CANBUS cables on the FL loom/clock.

Green 31 - Selector lever display

Green 18 - CAN high speed, power train (+)

Green 19 - CAN high speed, power train (â)

Green 20 - CAN high speed, power train (screening)

Green 22 - CAN low speed, convenience (+)

Green 23 - CAN low speed, convenience (â)

Greeb 24 - CAN low speed, convenience (screening)

Grey 5 - CAN high speed, display (+)

Grey 6 - CAN high speed, display (â)

Grey 7 - CAN high speed, display (screening)

These are the only two that's currently occupied. I'm going to assume they are correct but I'm hoping someone can confirm they are the right canbus cables for navigational display.

Green 22 - CAN low speed, convenience (+)

Green 23 - CAN low speed, convenience (â)

The only other little bits that I will need to wire up are the door, boot and bonnet sensors.

Then, assuming the rev counter kicks in, oil temp sensor works and everything else is tip top, its done.

To finish it off, I'll fix the dis, change the needle colours and enjoy it.

First off, the loom I used to make my PFL to FL clock loom was from a manual and as such it was missing the Auto gear selector cable. I'm not sure how this will change the clocks but I'm interested to see what it does.

It appears to come from the Red 20 pin connector on the PFL loom/clock and goes to the green plug on the FL loom/clock.

Red 6 - Selector lever position indicator to Green 31 - Selector lever position indicator

I'll wire that up as well.

If all goes well with the above I hope to wire up the RNS-d and get some navigation on the DIS as well.

Looking at the pinouts there is multiple CANBUS cables on the FL loom/clock.

Green 31 - Selector lever display

Green 18 - CAN high speed, power train (+)

Green 19 - CAN high speed, power train (â)

Green 20 - CAN high speed, power train (screening)

Green 22 - CAN low speed, convenience (+)

Green 23 - CAN low speed, convenience (â)

Greeb 24 - CAN low speed, convenience (screening)

Grey 5 - CAN high speed, display (+)

Grey 6 - CAN high speed, display (â)

Grey 7 - CAN high speed, display (screening)

These are the only two that's currently occupied. I'm going to assume they are correct but I'm hoping someone can confirm they are the right canbus cables for navigational display.

Green 22 - CAN low speed, convenience (+)

Green 23 - CAN low speed, convenience (â)

The only other little bits that I will need to wire up are the door, boot and bonnet sensors.

Then, assuming the rev counter kicks in, oil temp sensor works and everything else is tip top, its done.

To finish it off, I'll fix the dis, change the needle colours and enjoy it.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

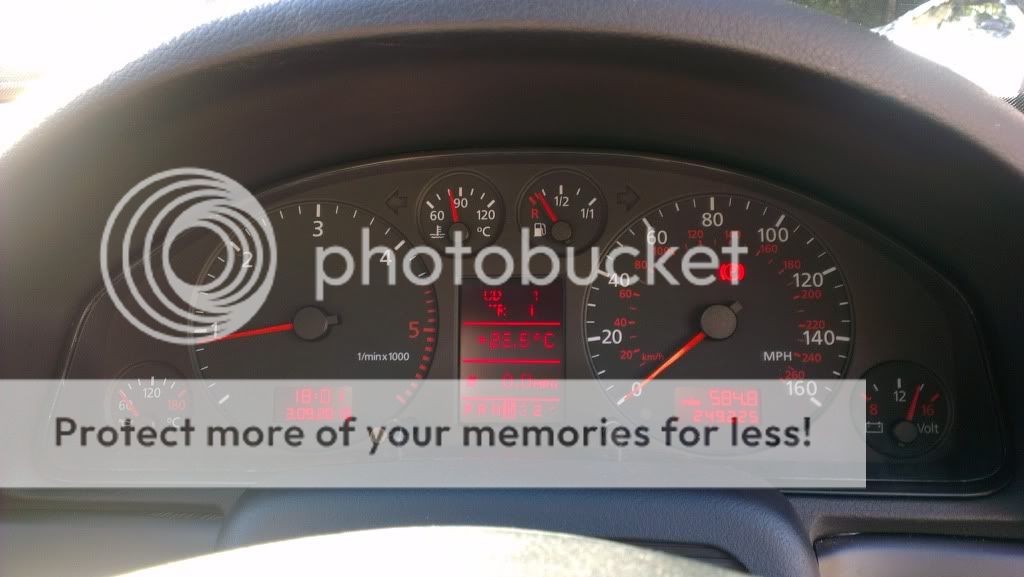

It works!!!!

If I had a working key is be driving it but I don't.

I need to get it up to temperature to make sure oil and coolant temps works properly.

I'll try that tomorrow when I get home.

I could not get the navigation display working.

I don't think the can bus wires are correct.

Bit more research needed.

If I had a working key is be driving it but I don't.

I need to get it up to temperature to make sure oil and coolant temps works properly.

I'll try that tomorrow when I get home.

I could not get the navigation display working.

I don't think the can bus wires are correct.

Bit more research needed.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Lets put a bit more info on this for anyone that's interested.

A quick edit of the conversion loom to add the selector sensor wire for the auto box and finding the oil sensor cable and it was ready to be plugged in and tested.

Found out what makes manual clocks in to Auto clocks and vice versa. Its all down to a selector sensor cable for the box.

With it it tells the clocks they are fitted to a auto so you get the warning and selector display, without it you get none of that.

Found the pinouts for the oil sensor and wired that up.

First test of the clocks and no oil sensor warning but low fuel and brake low warning. I earthed the brake sensor to cure the warning but had to leave the fuel cause I'm to lazy to drive and get some (I got fuel now).

With the brake cable sorted I was ready to see if I can get a key programmed.

At this point the clocks are looking a bit like this.

I did have a key programed to the clocks that worked but I can't find it. I a feeling that I might have chopped it up when I was playing about with a B7 key.

In my bag of key bits I found another immob transponder and attempted to code that but that never worked.

I spoke to @udiA3 who is pretty good at coding clocks, keys and such. He said give him a ring tonight and he'll talk me through it.

Hopefully we can get a key coded and I can drive the car to make sure temp gauges work.

Working from memory of what was working the last time I had the clocks in and the engine running (over 12 months ago I think), all the gauges worked apart from the Rev counter. I hope that's correct but I want to make sure the temp gauges work before I start swapping pins over and adding new plugs but if that's the case and it all works with no errors, fault codes or odd things happening, I can say this is complete and I'm running FL clocks in my PFL car.

Before I screw the clocks and hope I never have to remove them again I need to get my Navigational display working on the clocks, fix my DIS and convert my needles to white...........maybe, I'm not sure. I'll have a play.

A quick edit of the conversion loom to add the selector sensor wire for the auto box and finding the oil sensor cable and it was ready to be plugged in and tested.

Found out what makes manual clocks in to Auto clocks and vice versa. Its all down to a selector sensor cable for the box.

With it it tells the clocks they are fitted to a auto so you get the warning and selector display, without it you get none of that.

Found the pinouts for the oil sensor and wired that up.

First test of the clocks and no oil sensor warning but low fuel and brake low warning. I earthed the brake sensor to cure the warning but had to leave the fuel cause I'm to lazy to drive and get some (I got fuel now).

With the brake cable sorted I was ready to see if I can get a key programmed.

At this point the clocks are looking a bit like this.

I did have a key programed to the clocks that worked but I can't find it. I a feeling that I might have chopped it up when I was playing about with a B7 key.

In my bag of key bits I found another immob transponder and attempted to code that but that never worked.

I spoke to @udiA3 who is pretty good at coding clocks, keys and such. He said give him a ring tonight and he'll talk me through it.

Hopefully we can get a key coded and I can drive the car to make sure temp gauges work.

Working from memory of what was working the last time I had the clocks in and the engine running (over 12 months ago I think), all the gauges worked apart from the Rev counter. I hope that's correct but I want to make sure the temp gauges work before I start swapping pins over and adding new plugs but if that's the case and it all works with no errors, fault codes or odd things happening, I can say this is complete and I'm running FL clocks in my PFL car.

Before I screw the clocks and hope I never have to remove them again I need to get my Navigational display working on the clocks, fix my DIS and convert my needles to white...........maybe, I'm not sure. I'll have a play.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Been doing some more searching about cam bus, revs and came across this. I'm not sure how I've not read this section before.

Understanding differences between Audi A4 clusters and the compatibility issues

My speed works but not my Revs. I think this goes back to what LeeT said (might be others I can't remember) that the revs are taken from the ECU via can bus.

Understanding differences between Audi A4 clusters and the compatibility issues

Can Bus was introduced in some early 2000+ models which meant that vehicle in 1998-1999 didn't have can-bus and some clusters from 2001-2001.5 didn't work the tachometer or speedometer was not functional , that all depends on the version of the image software that cluster was loaded with.

My speed works but not my Revs. I think this goes back to what LeeT said (might be others I can't remember) that the revs are taken from the ECU via can bus.

- Joined

- May 25, 2012

- Messages

- 1,813

- Reaction score

- 200

- Points

- 63

- Location

- Hull, UK

- Website

- www.immotec.co.uk

I spoke to @udiA3 who is pretty good at coding clocks, keys and such. He said give him a ring tonight and he'll talk me through it.

Hopefully we can get a key coded and I can drive the car to make sure temp gauges work.

Glad I could be of assistance

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Glad I could be of assistance

Thanks for that mate.

Been out today and got the key coded to the clocks so it now starts and runs.

The wires are still a mess but it will do until I worked out the niggles.

I assumed the oil sensor was working fine cause I never got any errors but the errors only appeared when I started the car, which I could not do yesterday cause I was unable to start it. ******.

What are the niggles at the moment.

Revs counter don't work and it throws up a error about oil level.

Starts off ok, all looking good.

Then this little ******* pops up

Got oil and sensor is in correctly.

I thought it might have been my wiring of the oil level sensor but that appears ok going by the logs.

With the oil sensor unplugged or power removed I get one or both of these errors.

01311 - Information Data Bus

37-10 - Faulty - Intermittent

00562 - Sensor for Oil Level/Temperature (G266)

30-00 - Open or Short to Plus

With it plugged in and connected I get nothing. So I think its wired in correctly.

Talking to Byzan he said it could be the fact that I got no revs its causing the error.

The other error I'm getting is this

01314 - Engine Control Module

49-00 - No Communications

That might be the cause of the revs not working, which in turn might be the reason for the oil error I'm getting.

WIth the help of @udi A4 we tried coding my other keys but none of them worked. I got a random selection of keys in different states and condition. We think its cause all the keys have been coded before and wont code to the clocks.

In a last ditch effort to make sure I'm doing it right and the clocks work, we tried to code my main key with the clocks. It worked!! Brilliant.

Or not cause I forgot to tell @udi A3 that I don't have the SKC code for my old clocks and as such I can't recode the key to my old clocks.

So I'm kind of stuck now with semi working facelift clocks, which is ok as long the oil level sensor don't keep beeping at me.

@udi A3 can get SKC codes and code clocks, so he offered to come down and help me out but its about a 7 hour trip to get here for him, so I told him to stay home and if I get really stuck I'll meet him half way.

Thats my current even and state of affair with my clocks.

I've not attempted the RNS-d wiring yet. I want to get the clocks working.

Has anyone got any idea what I need to do to get the rev counter working?

New ECU?

Extra cables?

I looked in to what LeeT said about canbus being in the current ECU already but I can't find anything on the pin outs in ELSA.

I'm stuck and at a dead end I think.

HELP!!!!

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

- Joined

- May 25, 2012

- Messages

- 1,813

- Reaction score

- 200

- Points

- 63

- Location

- Hull, UK

- Website

- www.immotec.co.uk

Canbus comms errors are never good where the ecu is concerned. Check measuring blocks to see what isnt communicating. 125 ish I think

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Canbus comms errors are never good where the ecu is concerned. Check measuring blocks to see what isnt communicating. 125 ish I think

My car has not really got canbus.

The only canbus in it is what I fitted when fitting the stereo and that goes from the TV tuner to TMC, TMC to Radio.

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

As per MSN, those oil errors are pressure, not level.

Go check the pressure sensor wiring.

Soon as the rain stops and I'm out of work I will do just that.

Thanks.

I keep saying level and thinking of the sump sensor but Byzan said its the pressure.

jbh

TDi lover

- Joined

- Jan 3, 2010

- Messages

- 1,410

- Reaction score

- 171

- Points

- 63

- Location

- Slamannan/ Central Scotland

- Website

- www.retrobmw.co.uk

does the standard oil pressure switch give enough information out to give the clocks an accurate reading? ?I would check the part number of oil pressure switch with a newer one

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

does the standard oil pressure switch give enough information out to give the clocks an accurate reading? ?I would check the part number of oil pressure switch with a newer one

Just talking to Aragorn about it now.

Going by ETKA, the sensors are pretty much the same.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Chatting to Byzan and Aragorn about different things to try with these clocks.

One thing we wanted to check was the oil pressure switches, make sure it works, its the correct one for the facelift clocks. The coolant level sensor was changed when the cars went from PFL to FL, we was thinking it might be something like that.

Checking ETKA and they appear to be the same, so no issue there. Next was to make sure the clocks are seeing the oil pressure sensor and the changes it goes through when the engine is running and such.

Ignition on, engine off.

Ignition on and engine running.

Oil pressure is ok, so it has to be all down to the lack of revs.

Reading on some forums, it might be able to get it working by flashing the clocks with some Eprom software. This needs a bit more looking in to before I start randomly flashing my clocks.

I also tried setting the clocks up differently. different engines, different number of cylinders and such. that never made a difference.

One thing we wanted to check was the oil pressure switches, make sure it works, its the correct one for the facelift clocks. The coolant level sensor was changed when the cars went from PFL to FL, we was thinking it might be something like that.

Checking ETKA and they appear to be the same, so no issue there. Next was to make sure the clocks are seeing the oil pressure sensor and the changes it goes through when the engine is running and such.

Ignition on, engine off.

Ignition on and engine running.

Oil pressure is ok, so it has to be all down to the lack of revs.

Reading on some forums, it might be able to get it working by flashing the clocks with some Eprom software. This needs a bit more looking in to before I start randomly flashing my clocks.

I also tried setting the clocks up differently. different engines, different number of cylinders and such. that never made a difference.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

Bit more digging and reading.

The eeprom idea won't work.......well it might but there is a chance of bricking the clocks and if that did not happen, the date time acts up and other gauges don't work. So I'm knocking the on the head.

Reading on another forum, a guy found can bus cables on none can bus ecu (can't remember if this is the sane info Lee posted).

But I double checked the info with a newer version of my ecu.

I compared the pin out of my 98 ecu with the pins of 99 ecu. With the hand full of pins I checked they was all the same but the 99 ecu had extra pins at 68 and 75 for the can bus.

I checked my plugs and these pins are empty. I got some pins and put them in ready.

For tomorrow I plug the ecu can bus pins I added in to my clocks.

The next stumbling block I can think of is that my ecu don't have the can bus enabled.

So its back to eeproms (I guess) or finding a 99 AFN ecu with can bus that might still work with my engine.

The eeprom idea won't work.......well it might but there is a chance of bricking the clocks and if that did not happen, the date time acts up and other gauges don't work. So I'm knocking the on the head.

Reading on another forum, a guy found can bus cables on none can bus ecu (can't remember if this is the sane info Lee posted).

But I double checked the info with a newer version of my ecu.

I compared the pin out of my 98 ecu with the pins of 99 ecu. With the hand full of pins I checked they was all the same but the 99 ecu had extra pins at 68 and 75 for the can bus.

I checked my plugs and these pins are empty. I got some pins and put them in ready.

For tomorrow I plug the ecu can bus pins I added in to my clocks.

The next stumbling block I can think of is that my ecu don't have the can bus enabled.

So its back to eeproms (I guess) or finding a 99 AFN ecu with can bus that might still work with my engine.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

- Joined

- Jan 30, 2008

- Messages

- 18,708

- Reaction score

- 909

- Points

- 113

- Location

- Glenrothes, Fife, Scotland

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

jbh

TDi lover

- Joined

- Jan 3, 2010

- Messages

- 1,410

- Reaction score

- 171

- Points

- 63

- Location

- Slamannan/ Central Scotland

- Website

- www.retrobmw.co.uk

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

wow nice one!

How did you find that?

Chatting to Byzan about channel 60 in Adaptation.

It appears to only be there in facelift clocks.

- Joined

- Nov 24, 2010

- Messages

- 15,084

- Reaction score

- 1,131

- Points

- 113

- Location

- Plymouth

- Website

- wheelsnwires.blogspot.com

I'm going back over the wiring diagrams with the intent of spending a saturday cleaning this mess of wires up.

my intention is to properly wire all the cables up and make it final.

I sat down yesterday going through the pin outs of each cluster and matching them up. It looks like this at the moment.

The cluster is in and working and all systems that I use on a daily basis appears to be fine.

Throttle, cruise control and lights.

This is the list of pins from 98 that I'm not sure where they go on 00. I got a slight idea but I just want to double check.

Green 4 -Immobilizer

I can't find facelift version of this on the pin outs but with my testing earlier it appears the Immob works, so I guess I can just tape this up and ignore it?

Green 14 -Electronic throttle

The facelift version of this seems to be on Blue 13 -Electronic throttle / glow period warning lamp. I'm a little bit reluctant of connecting the Electronic throttle to this pin cause Blue 13 on the prefacelift loom is Glow period warning lamp or CAT, this seems to match up with Blue 13 on the facelift loom and since the throttle works, I guess its ok but I'm a little paranoid about the glow plugs.

Green 15 -Parking lights.

Can't find the face lift version of this at all. I'll test it over the weekend.

Red 10 -Hydraulic pressure.

Not sure if this is oil or brakes but everything is working. I guess its not needed?

Red 17 -Glow plug relay (on TDI engines the low-voltage monitor in the instrument cluster is disabled while the glow plugs are activated).

Can't find this on the facelift plugs.

Out of the above pins that I can't find my main concern is the glow plugs.

The glow plug light comes on and then goes off but that's normal when its this warm but I'm worried that that glow plugs are not working at all.

I'm not sure how to test the glow plugs and I don't really want to wait till the winter and see if I can start the car when its -3 out side.

Anyone got any idea how I can test the glow plugs to make sure they are working correctly?

my intention is to properly wire all the cables up and make it final.

I sat down yesterday going through the pin outs of each cluster and matching them up. It looks like this at the moment.

The cluster is in and working and all systems that I use on a daily basis appears to be fine.

Throttle, cruise control and lights.

This is the list of pins from 98 that I'm not sure where they go on 00. I got a slight idea but I just want to double check.

Green 4 -Immobilizer

I can't find facelift version of this on the pin outs but with my testing earlier it appears the Immob works, so I guess I can just tape this up and ignore it?

Green 14 -Electronic throttle

The facelift version of this seems to be on Blue 13 -Electronic throttle / glow period warning lamp. I'm a little bit reluctant of connecting the Electronic throttle to this pin cause Blue 13 on the prefacelift loom is Glow period warning lamp or CAT, this seems to match up with Blue 13 on the facelift loom and since the throttle works, I guess its ok but I'm a little paranoid about the glow plugs.

Green 15 -Parking lights.

Can't find the face lift version of this at all. I'll test it over the weekend.

Red 10 -Hydraulic pressure.

Not sure if this is oil or brakes but everything is working. I guess its not needed?

Red 17 -Glow plug relay (on TDI engines the low-voltage monitor in the instrument cluster is disabled while the glow plugs are activated).

Can't find this on the facelift plugs.

Out of the above pins that I can't find my main concern is the glow plugs.

The glow plug light comes on and then goes off but that's normal when its this warm but I'm worried that that glow plugs are not working at all.

I'm not sure how to test the glow plugs and I don't really want to wait till the winter and see if I can start the car when its -3 out side.

Anyone got any idea how I can test the glow plugs to make sure they are working correctly?

jbh

TDi lover

- Joined

- Jan 3, 2010

- Messages

- 1,410

- Reaction score

- 171

- Points

- 63

- Location

- Slamannan/ Central Scotland

- Website

- www.retrobmw.co.uk

could you not just connect a test meter up to one of the glow plugs when the engines cold and then turn the ignition on and see if there is power going to them? earth it off the body and the live to the glow plug

jbh

TDi lover

- Joined

- Jan 3, 2010

- Messages

- 1,410

- Reaction score

- 171

- Points

- 63

- Location

- Slamannan/ Central Scotland

- Website

- www.retrobmw.co.uk

could you not just connect a test meter up to one of the glow plugs when the engines cold and then turn the ignition on and see if there is power going to them? earth it off the body and the live to the glow plug

Or stick a 5w bulb between the bolt (terminal) end of the plug, and the body ground