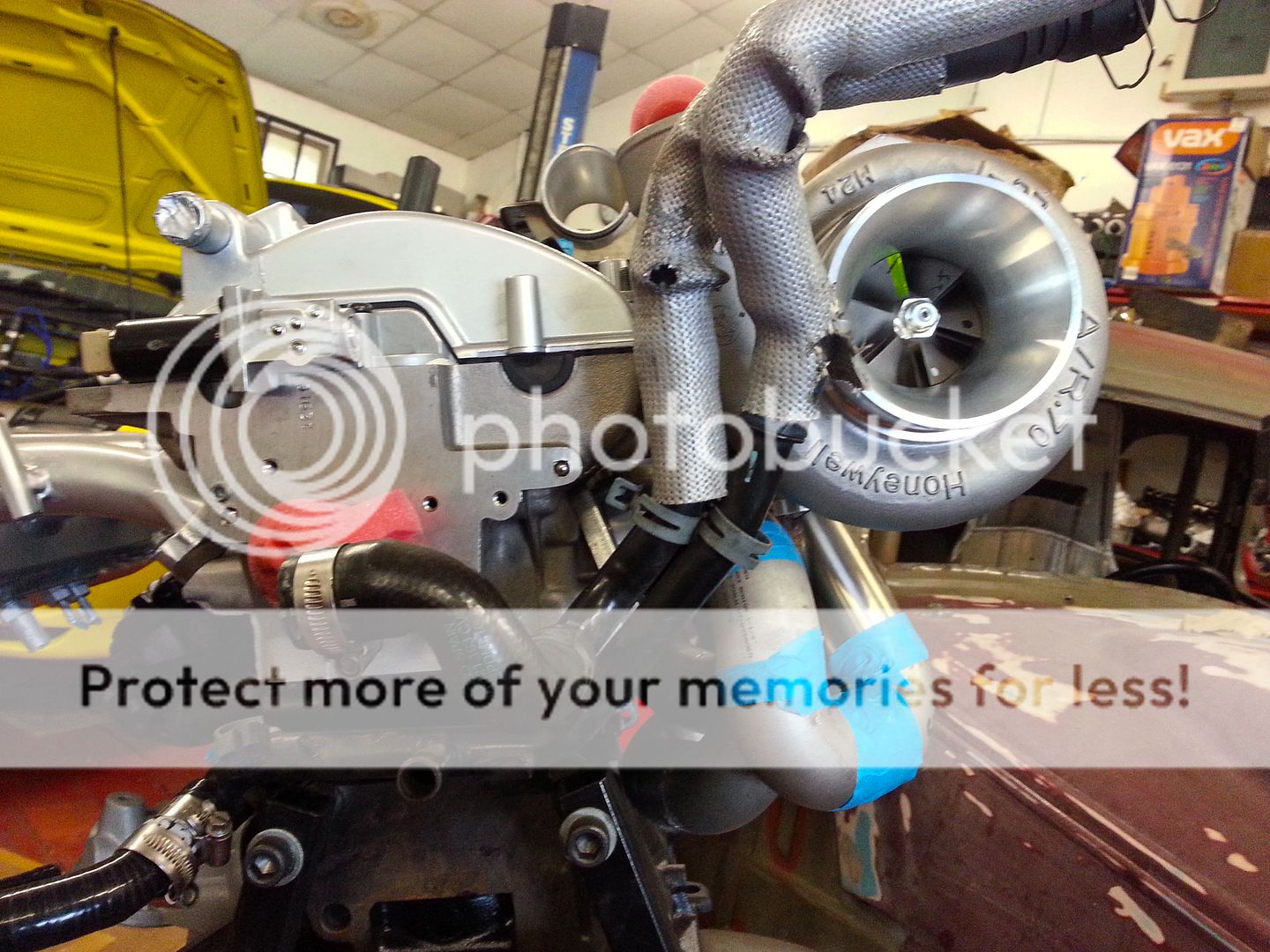

feck that lol... biggest we can fit in there dude

'because we can'

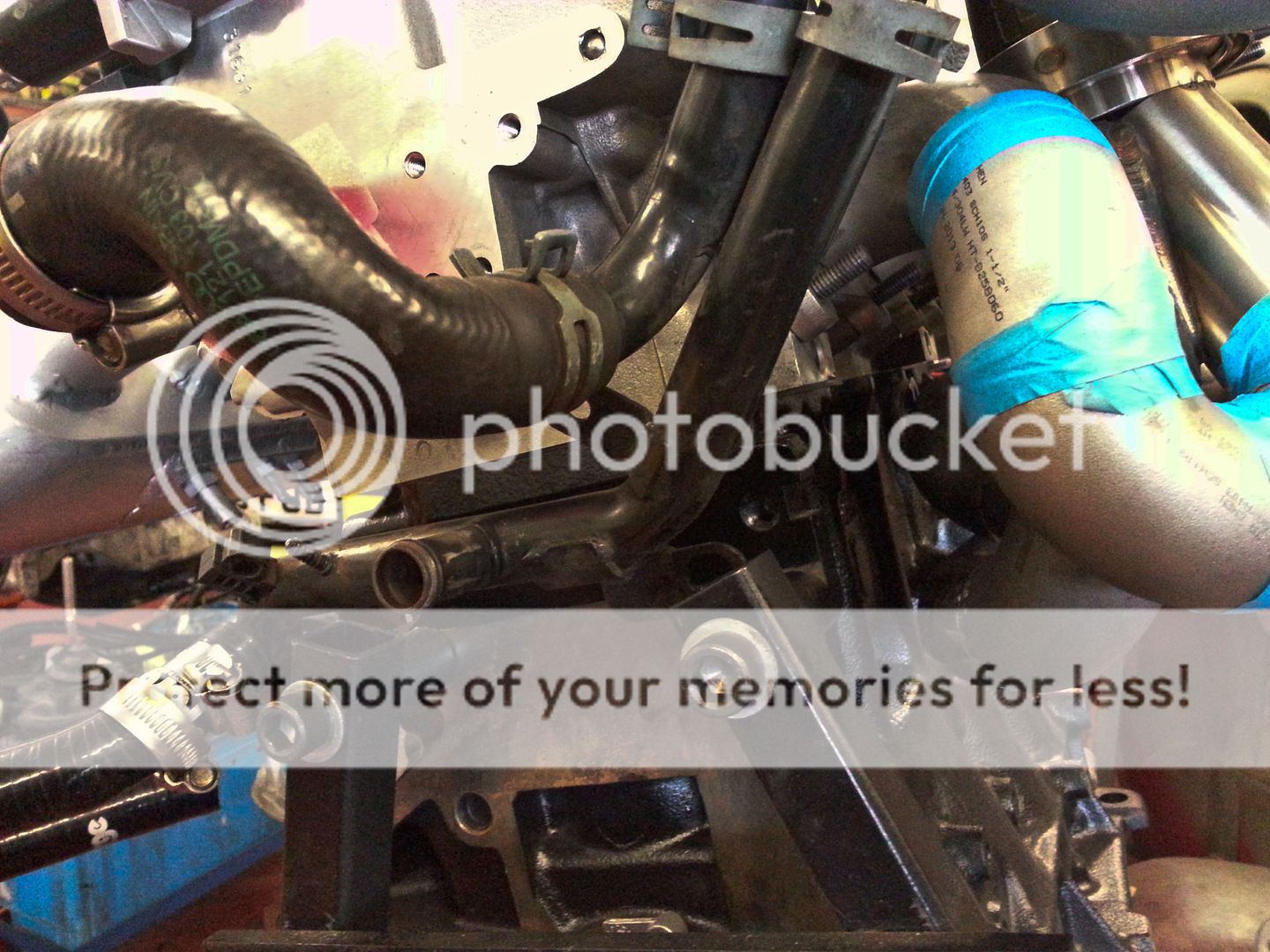

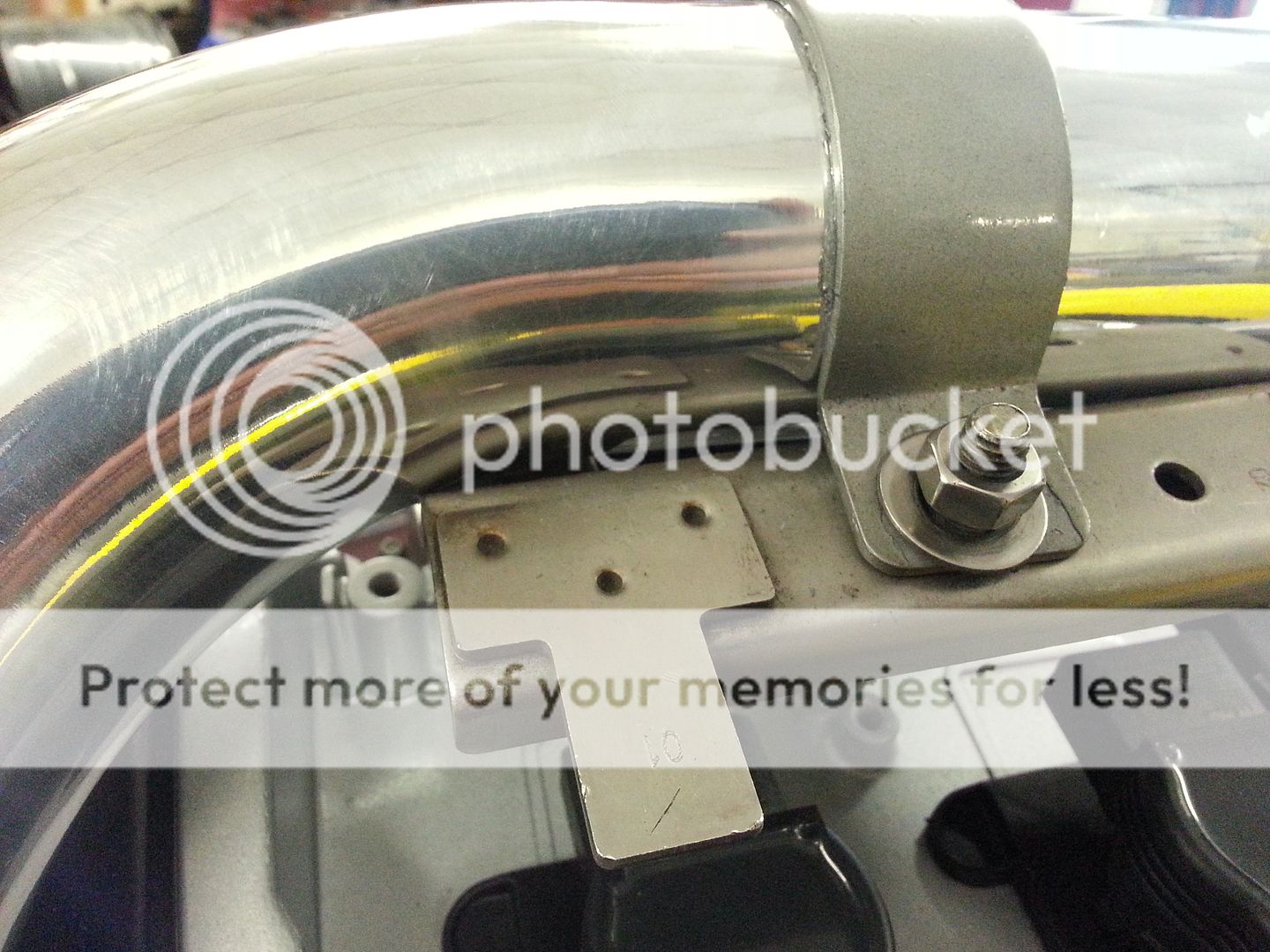

and straight out the side

like so

Last edited by a moderator:

feck that lol... biggest we can fit in there dude

'because we can'

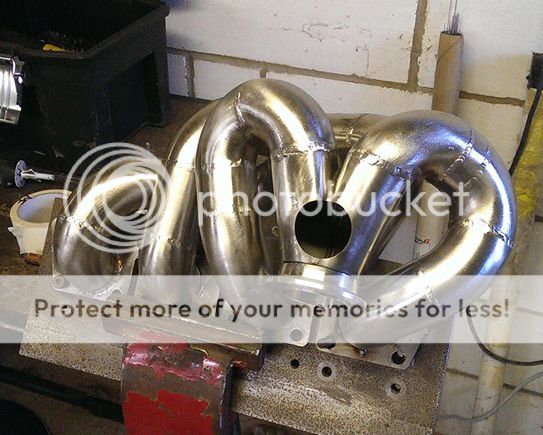

Fingers crossed this doesn't buckle the flange too much during welding. Distortion is a b*tch

You can rest assured I will not be having a side exit exhaust, screamer pipe or running 40psi

<tuffty/>

You can rest assured I will not be having a side exit exhaust, screamer pipe or running 40psi

<tuffty/>

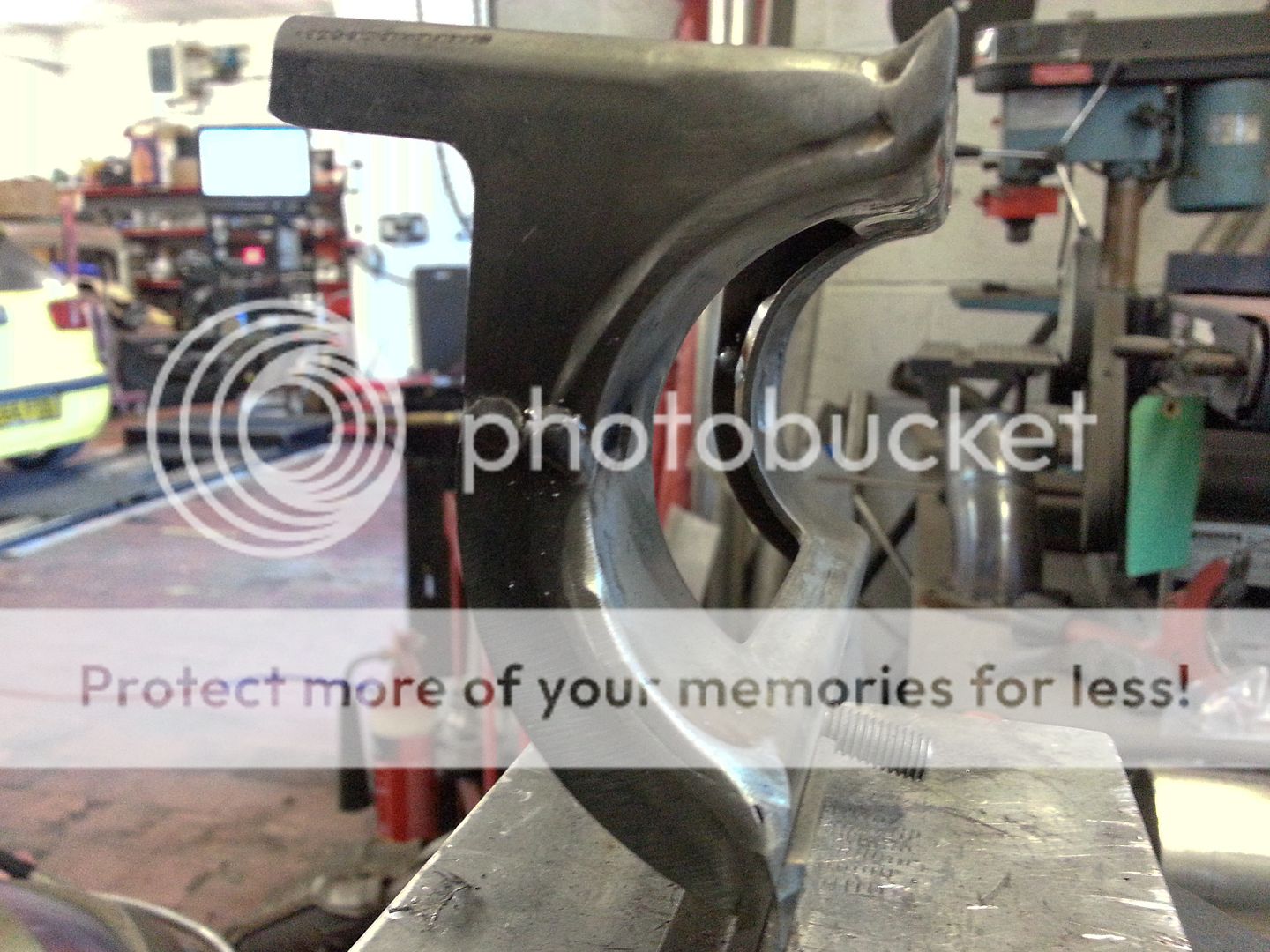

Done well there, not even the comp housing touching the head....:icon_thumright:

Nice looking manifold! Could you take some measurements of the turbo? I would like to know the diameter of the housings and the total lenght of turbo. I could compare how my stone age turbo (Holset HX35) compares to Yours in size, so would know how tight fit mine will be.

Is that coolant kit a special order? I didn;t get those two hoses in my kit :-(

No special order... just what came with the kit Forge gave me... TT kit iirc...

<tuffty/>

I had a kit based on FMKCTT225 which is the TT one... they didn't have an S3 one at the time and built the kit off my feedback... yours should have the joining hose from the coolant housing on the head to the hard pipe and the pipe to the after run pump which my kit didn't have

<tuffty/>

Hour many hours labour we talking for the welder to complete what you've started??

I think later next year if I have the time il hopefully have learnt at least to tack a weld (wana buy a Clarke mig).

so would be keen to build a mani out of mild steel and have a pro put it all together.

So many skills I want to learn, not enough time to do it lol.

Can't wait for it to come together, itl look great once in the bay.

Hour many hours labour we talking for the welder to complete what you've started??

I think later next year if I have the time il hopefully have learnt at least to tack a weld (wana buy a Clarke mig).

so would be keen to build a mani out of mild steel and have a pro put it all together.

So many skills I want to learn, not enough time to do it lol.

Can't wait for it to come together, itl look great once in the bay.

Tufty has been given special dispensation to fab his own...( Bills secretly paying me to get it done so he can have his garage back!!!!!)

Personally its very hard to redo someone elses work. Mines th other manifold for my HTA wheeled GT30 turbo.

Shouldn't you be welding something?

cant, waiting for tufty to stop fannying around with brackets and covering his manifold in oil again and get me his wastegate tacked *cough* on.

cant, waiting for tufty to stop fannying around with brackets and covering his manifold in oil again and get me his wastegate tacked *cough* on.

Tufty has been given special dispensation to fab his own...( Bills secretly paying me to get it done so he can have his garage back!!!!!)

Personally its very hard to redo someone elses work. Mines th other manifold for my HTA wheeled GT30 turbo.