Quick update...

I have now had a chance to change the oil pump.... was pleased to see the sump still looking good after around 15/20k of motoring since I started the work on the car...

...removed the old pump which still looks ok tbh but peace of mind etc...

...refitted the pump and cleaned out the pickup.. I would have just fitted a new one but Bill didn't have on on the shelf... it wasn't clogged or damaged so all good...

Having the sump off gave me a chance to look at how clean the engine was still so pleased with my current 5/6k oil change regime...

Sadly though this didn't cure the rattling top end entirely... its is much quieter and the engine seems much better and smoother at lower revs but the rattle on idle is still there so I have come to the conclusion that the highish mileage of the large port head I currently have (200k I think) maybe a little more worn than first thought...

My current thought is that excessive follower bore wear is causing the oil pressure in general in the head to be a little lower than normal and the followers aren't getting all the oil they need and thus getting the rattle... I also think this could be the cause of my running issues at low rpm on part throttle where I get random hiccups from the engine that feel like hitting limp (which technically my ECU no longer can do properly)... the issue manifests itself from around 3k to 4k rpm in gears like second on part throttle where the car is gradually building speed/revs then hits a huge flat spot that feels like a boost pipe coming off and my current theory is that the oil pressure drops a little allowing the load of the cam lobes to compress the followers a little and thus create a flat spot... under WOT acceleration all feels good but its slow acceleration of 'town' style driving where this seems more evident..

I could also have ******** followers of course but I cannot remember having a rattling top end when they were in the AMK head and the issue has been less frequent (although just as random which suggests its not mapping related) since fitting both the new cam tensioner and the new oil pump...

The only thing left to do here really is to eliminate the head as an issue by just getting another... I may end up with another small port I guess as large port heads are thin on the ground and I can look at sourcing one from a newer 20v motor as I am going to avoid anything with space miles on it... I may also change all the followers yet but they aren't cheap to buy costing just over £20 a pop at ECP and just over £200 (plus postage, tax etc) to import a full set...

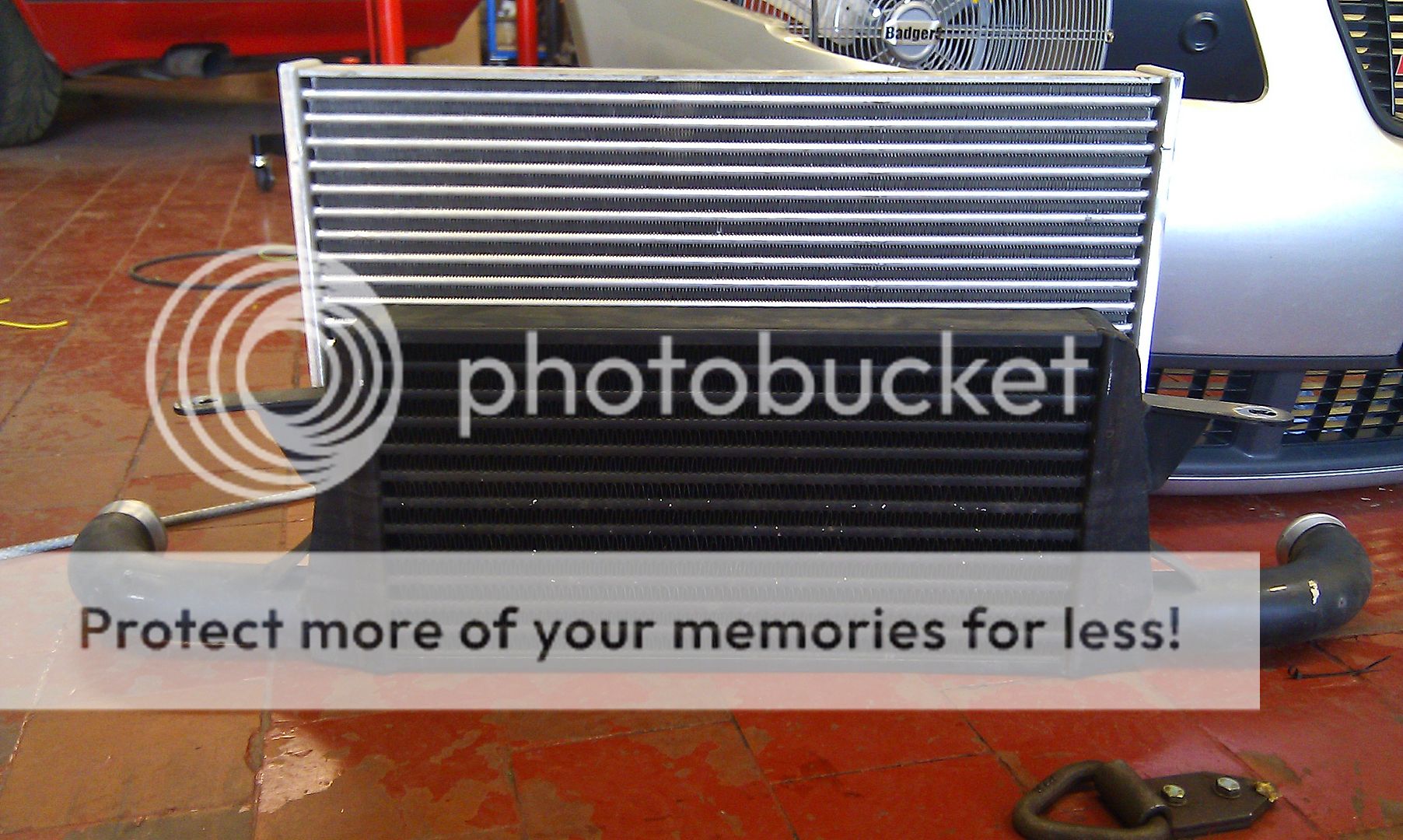

Anyhoo... I also spent a bit of time measuring up for a larger FMIC... Alex at AH Fabs suggested the core he uses for his cossie FMIC's

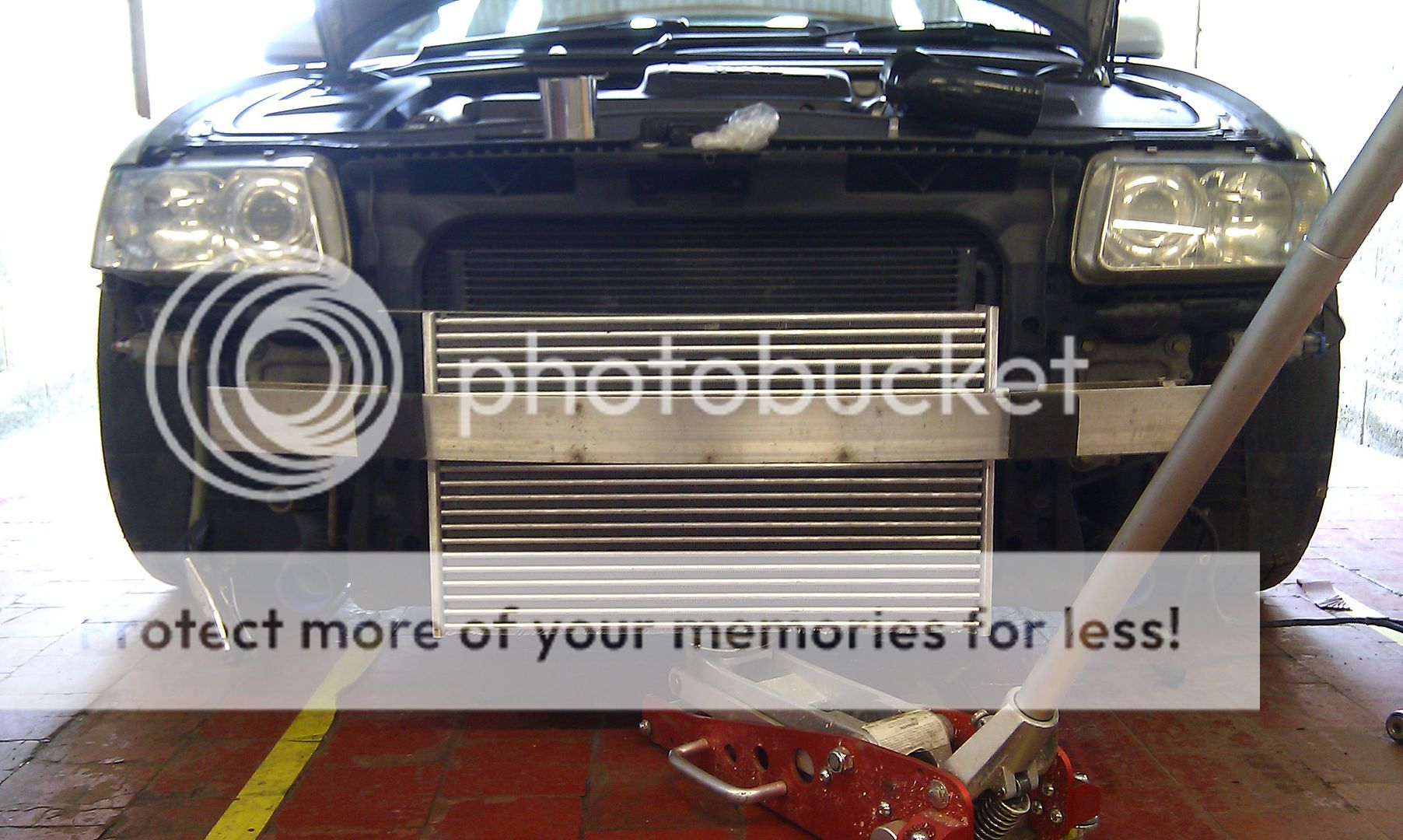

25 rows compared to 13 on the current AH Fabs S3 FMIC... same depth but taller and a tad wider... so cut a template out to see where the core would fit compared to the current one... I fitted the template behind the original FMIC lining it up at the bottom... quite a bit bigger!..

End tanks and outlets are much further into the curvature of the bumper...

...and with the bumper on the top of the core will protrude out from the top grille... (black mark indicates depth of the core)...

...so... won't actual fit then! boooo

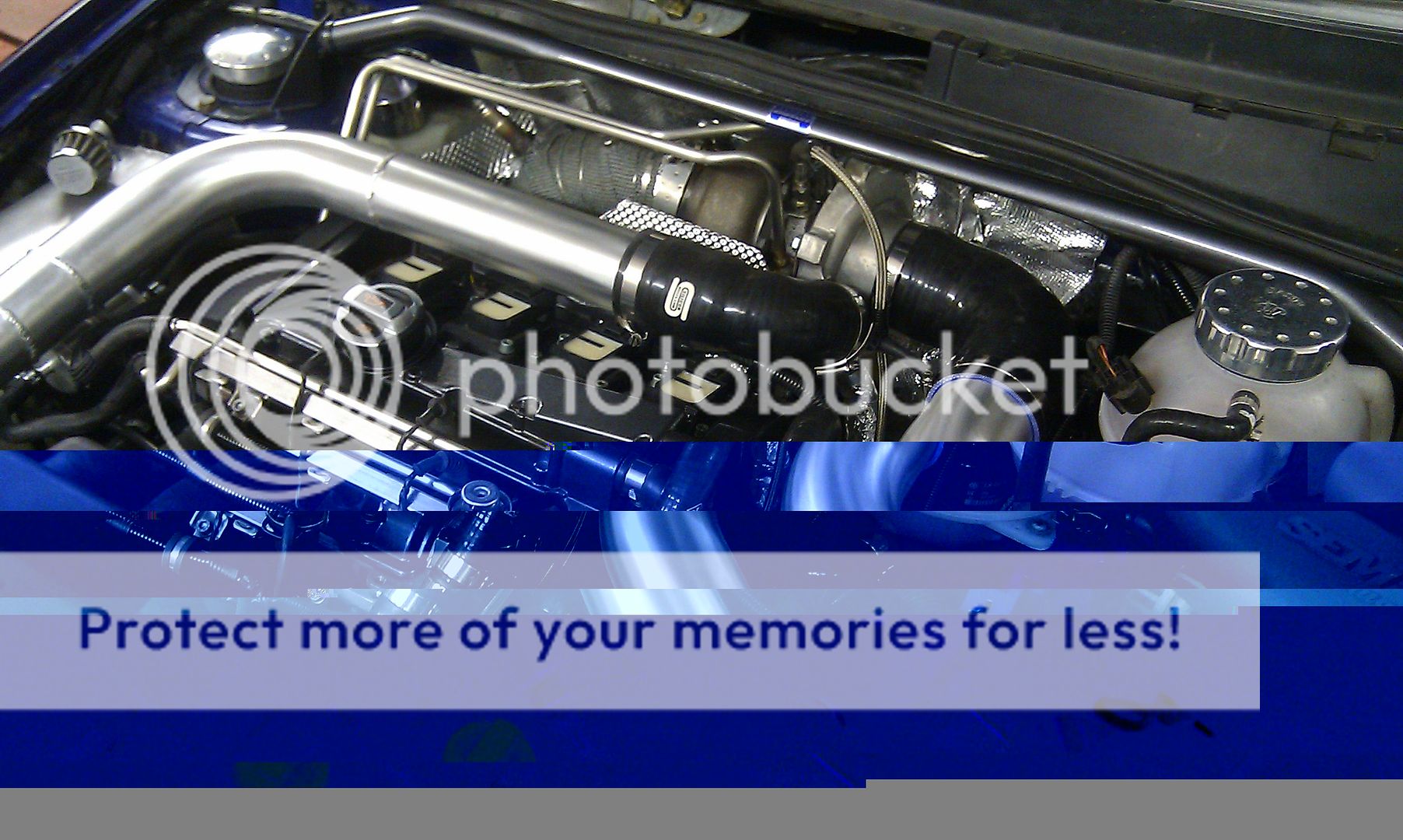

Back to the drawing board then... will have a chat with Alex next week to discuss core options... one option I want to look into is a deeper core say 76mm odd maybe... I need more flow more than cooling ability and I reckon I can get the outlets at the top like the pro alloy one here...

...the S3 has headlight washers in the way of the pipe run pictured above so I will have to change the route a bit but I reckon I could get something like this to work...

Onwards and upwards!

<tuffty/>