Busy couple of days sorting stuff out, turbo is away at last and hopefully should fine out the prognosis tomorrow...

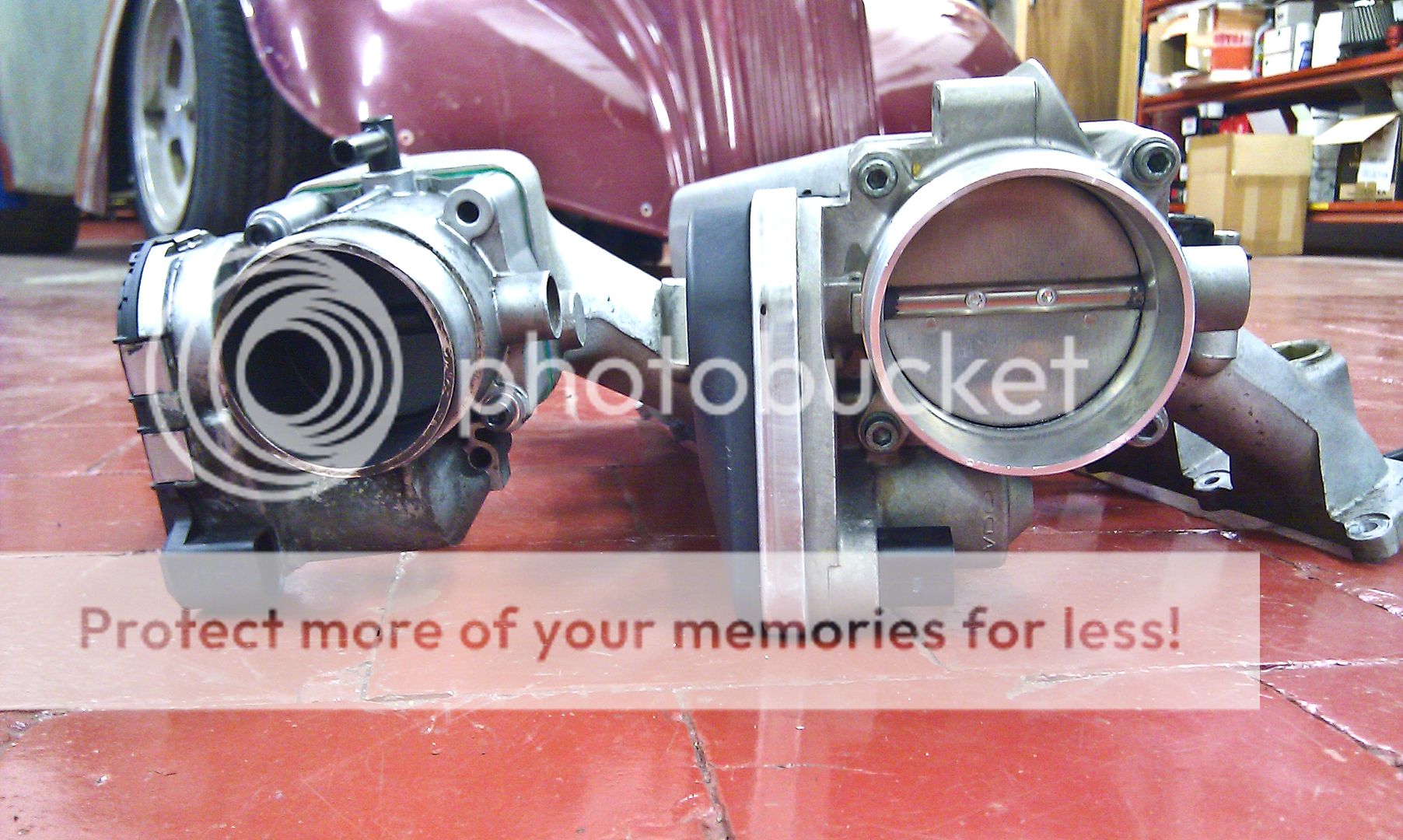

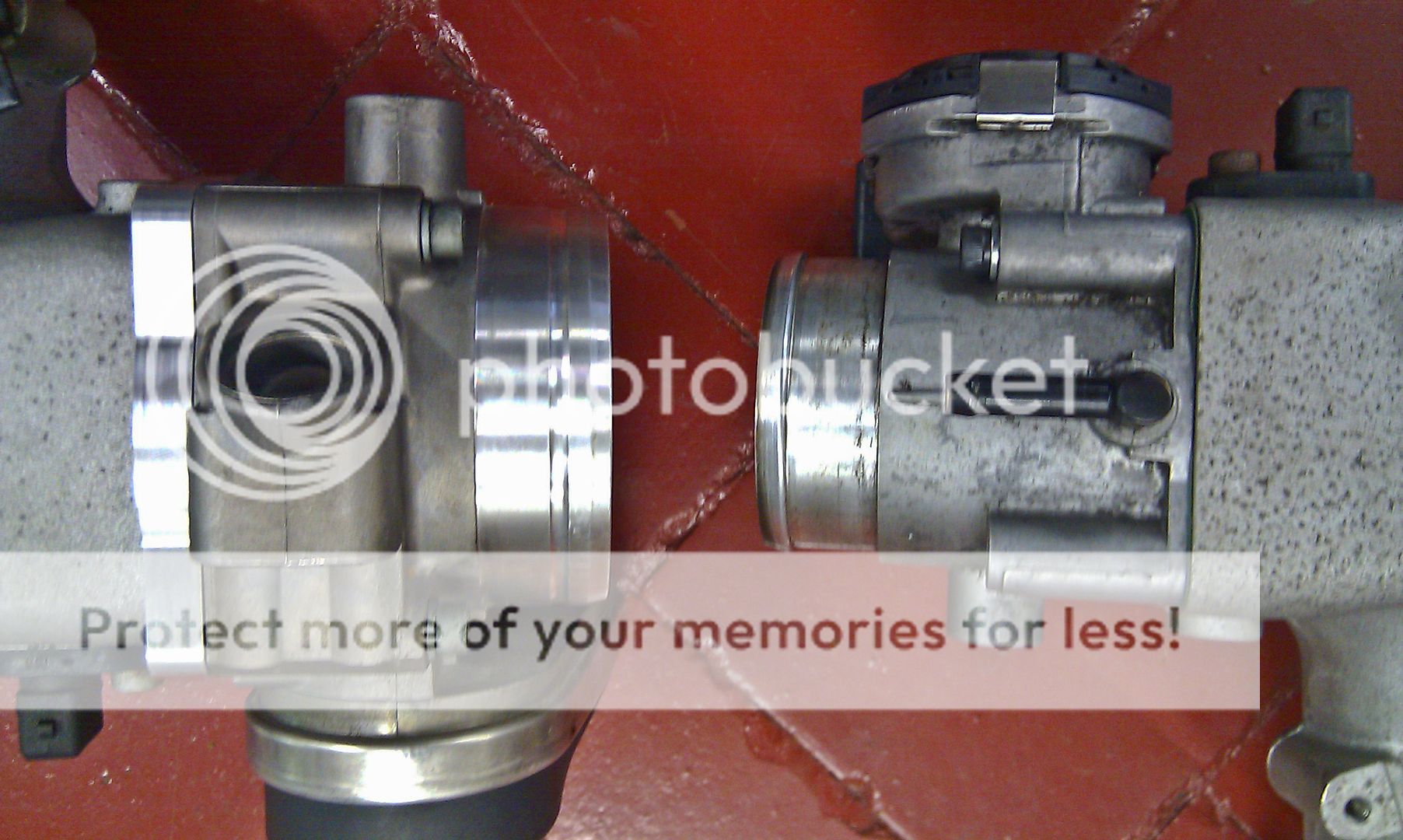

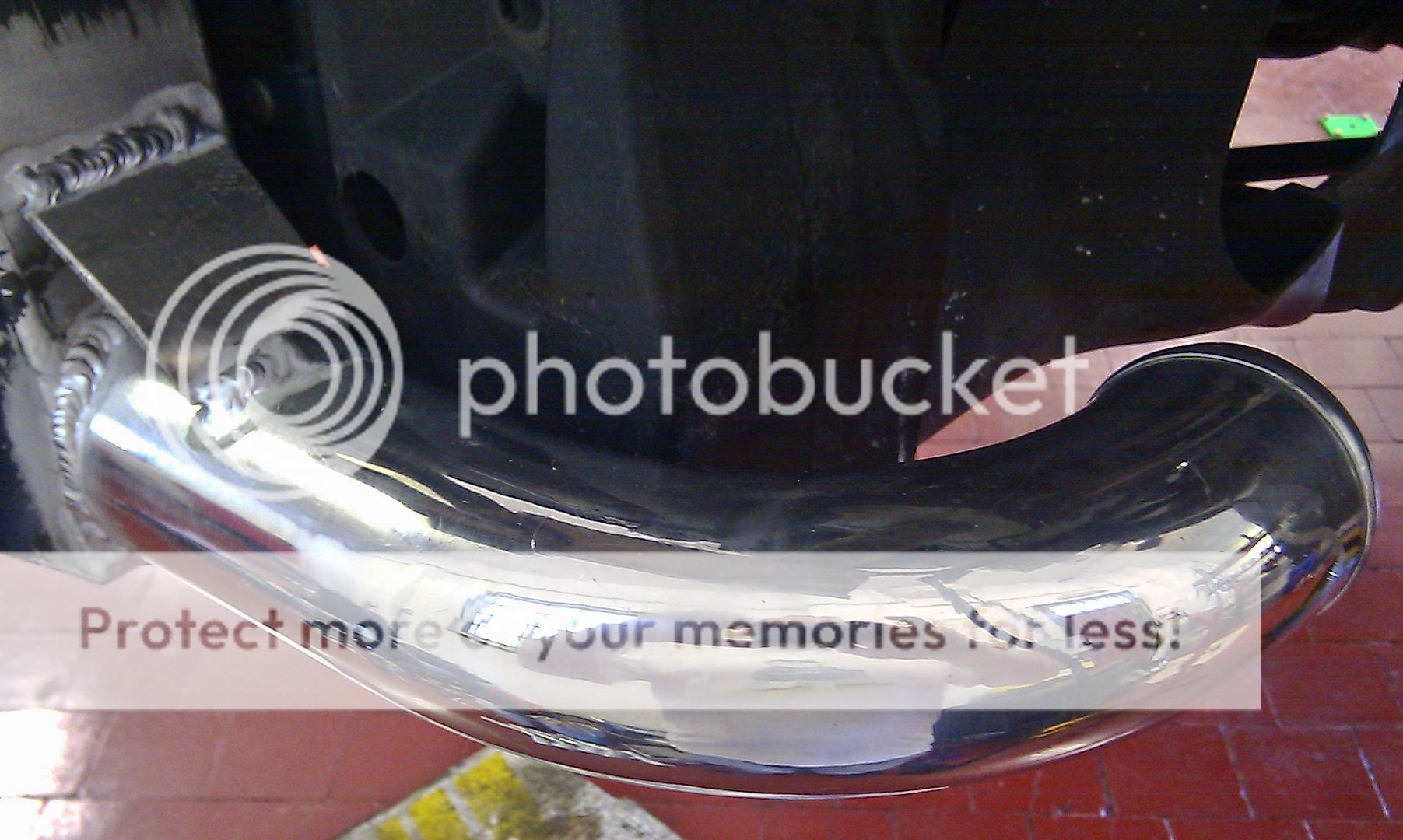

FMIC is now repainted and on the car, I have been sorting out the pipework and nearly finsihed it all... finding silicon to fit the R32 throttle body has been a challenge but using a similar approach the to big turbo Polo that rolled out of Badger 5 a little while back I have gone for an SFS 83mm to 70mm straight reducer (in black of course) that will lead onto a 70mm 90 degree alloy bend that will then be welded to the 60mm pipework by skillage and magic...

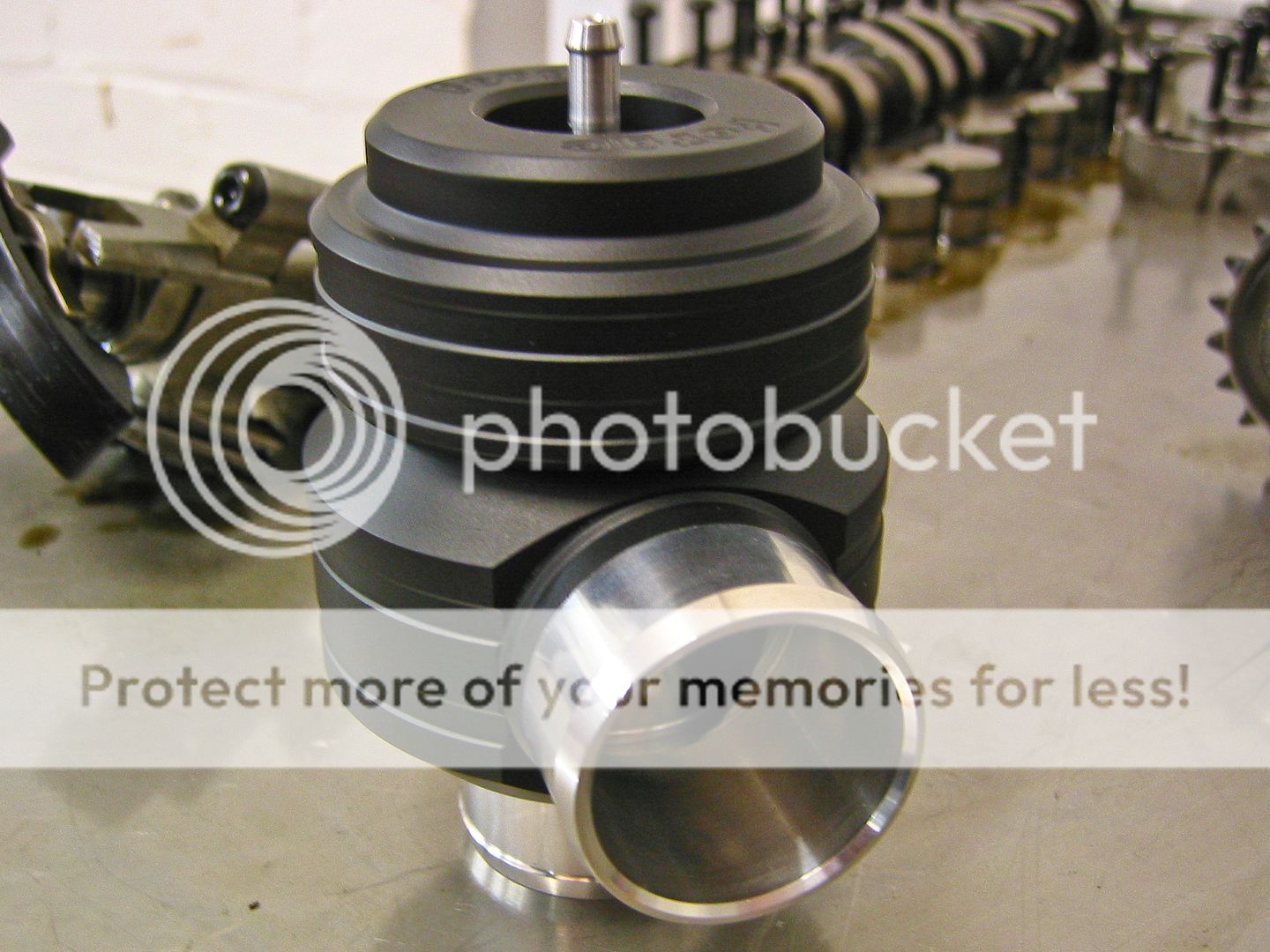

I have also been toying with the TIP and positioning of the super size DV... I think I may have to compromise the OEM look a tad as I have far too many 'large' things under the bonnet to fit it all out of sight but I have a couple of ideas that I can try out once I have picked up the bends to build a new TIP as its better than just welding plates over the holes in the old one... there is only going to be one connection going into the TIP this time, the DV... the charcoal breather, N75 vent (as I don't use an N75) and PCV are being ditched... only thing going into my turbo is air....

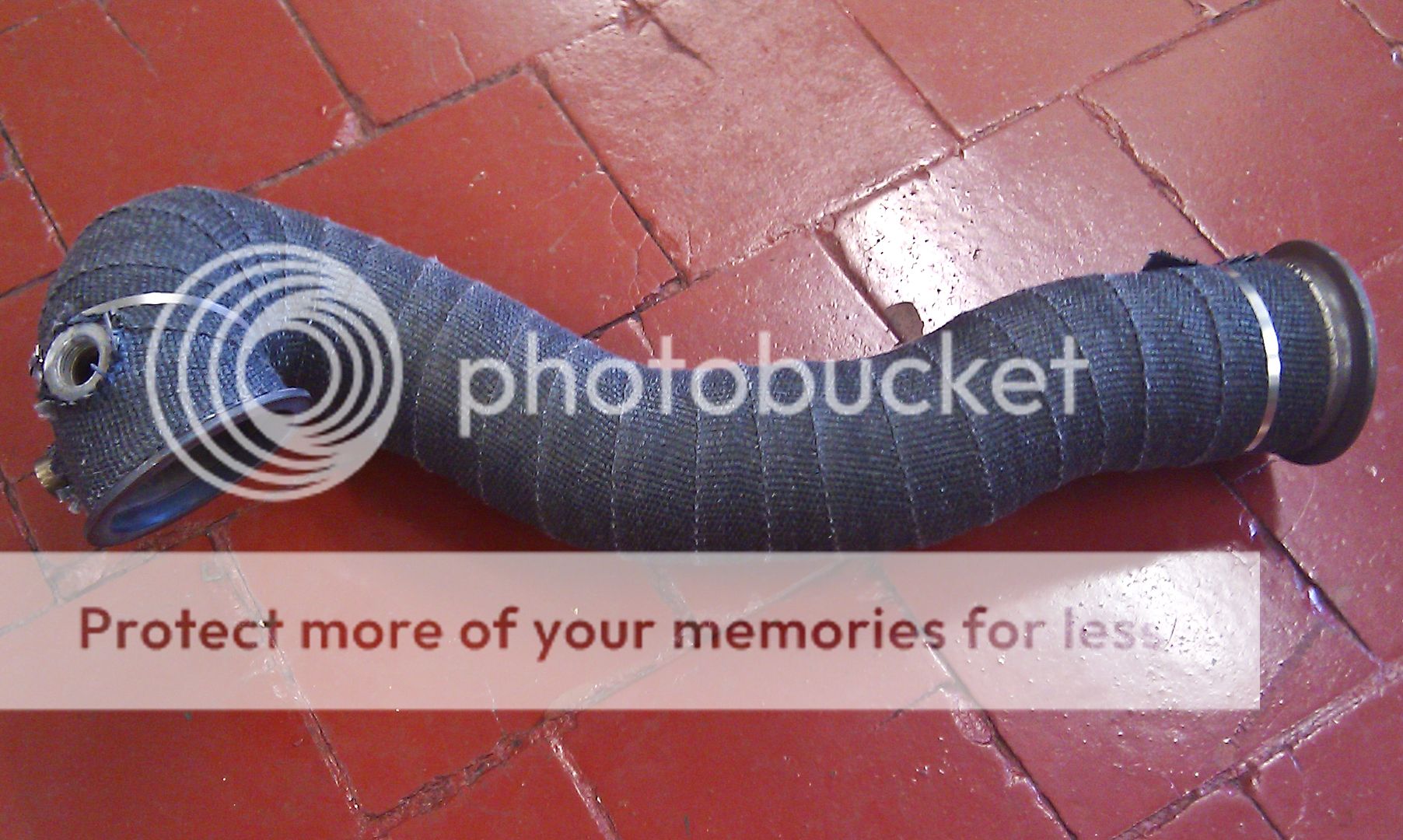

Another job I did was to re-wrap the downpipe as even though the wrap itself had plenty of life left, it was looking a little battle weary from the early days before I sorted the mounts out properly and its position.... the prop shaft had cut into the wrap and shredded it a little...

Before...

After...

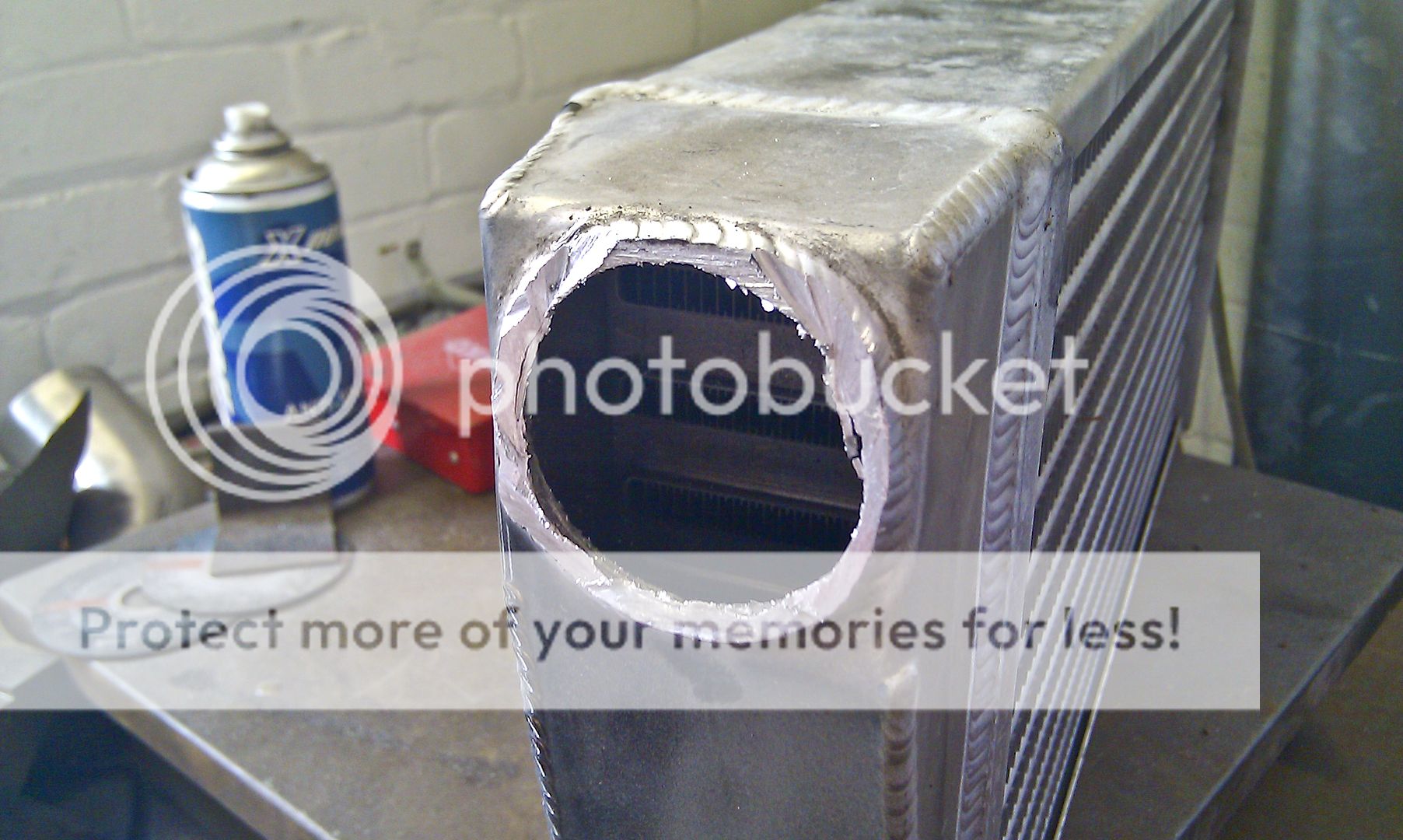

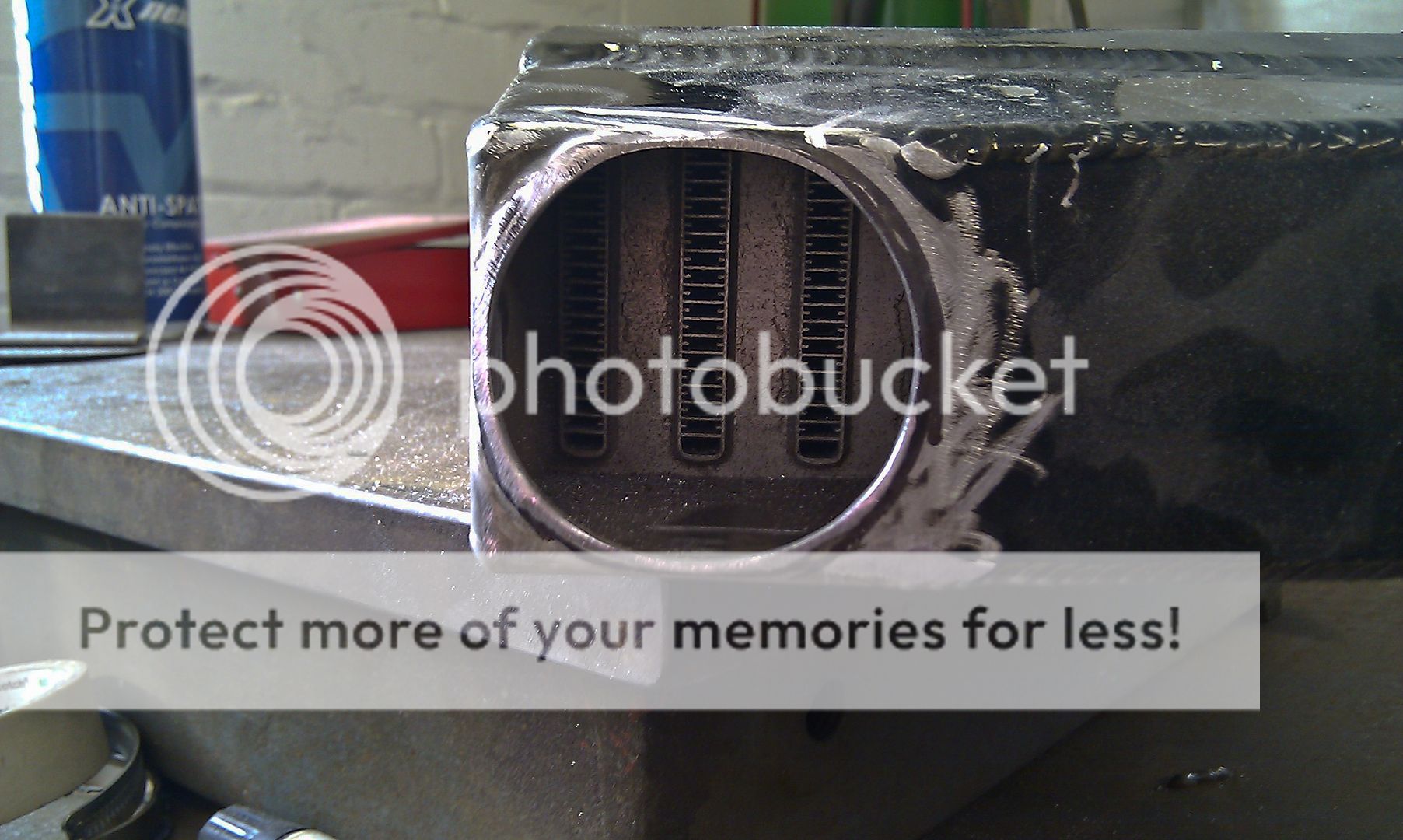

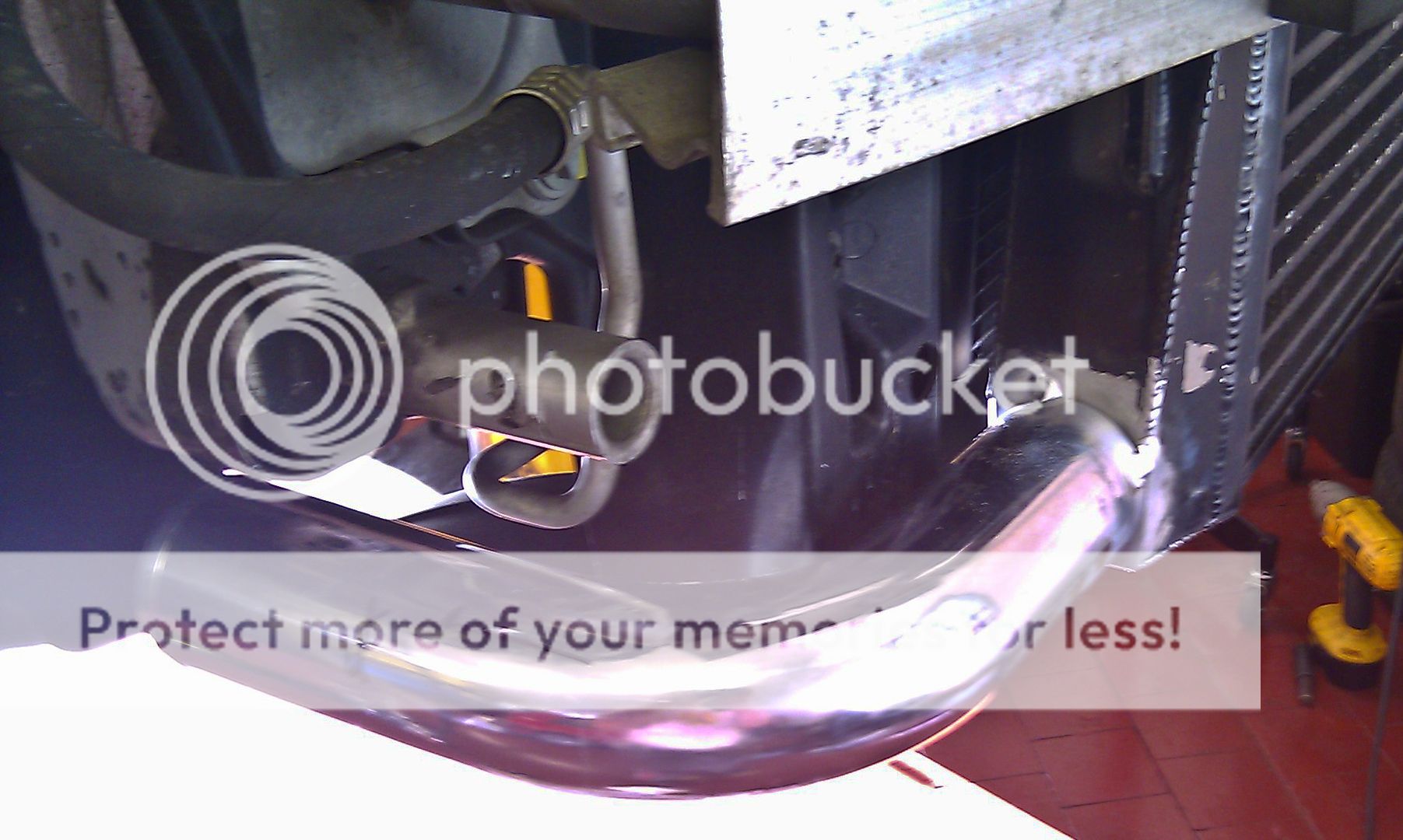

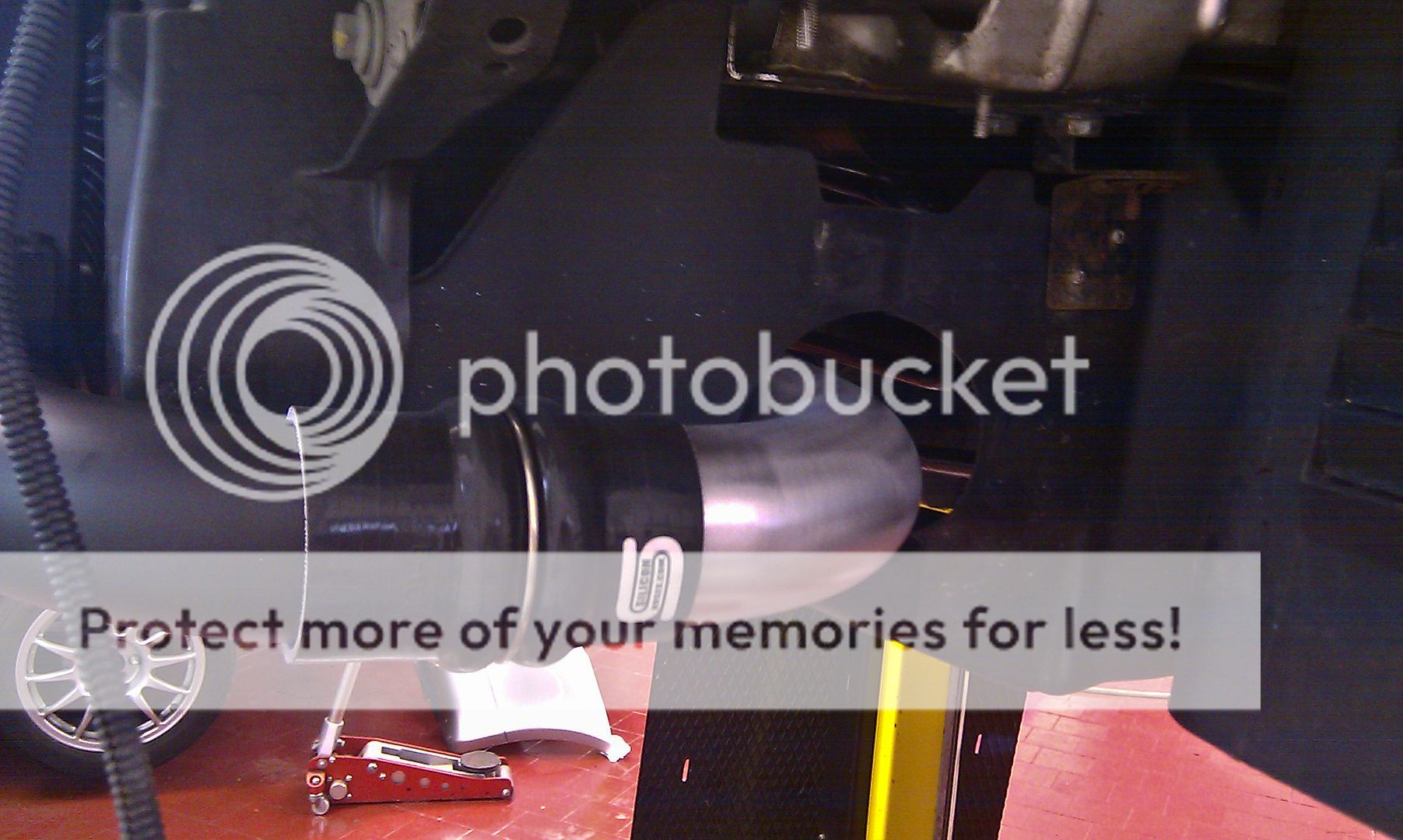

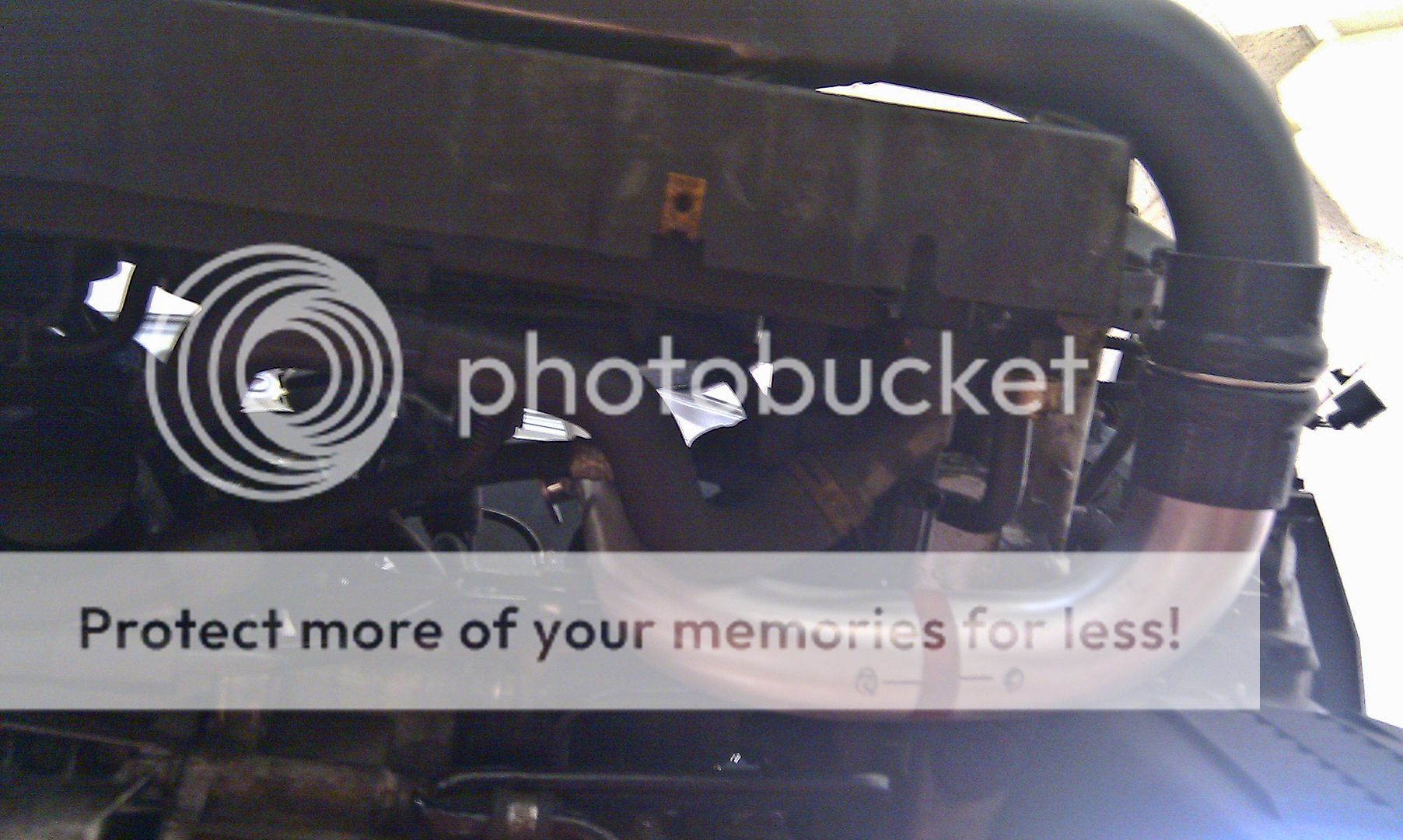

Pictures of the FMIC installation so far...

Painted... (only the front face with a fairly light coat)

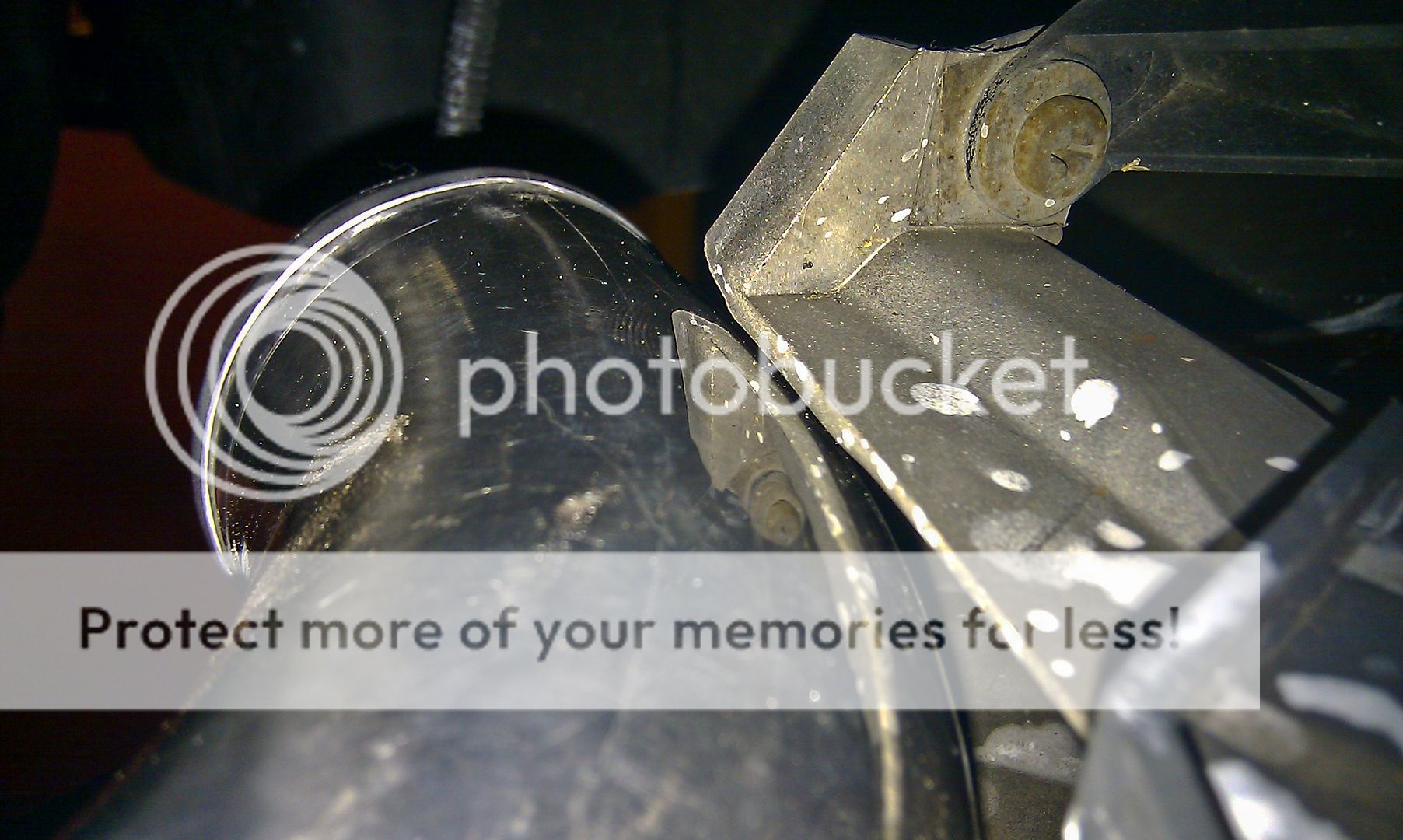

Offside pipe work (complete with welding tape TM)

Nearside pipework...

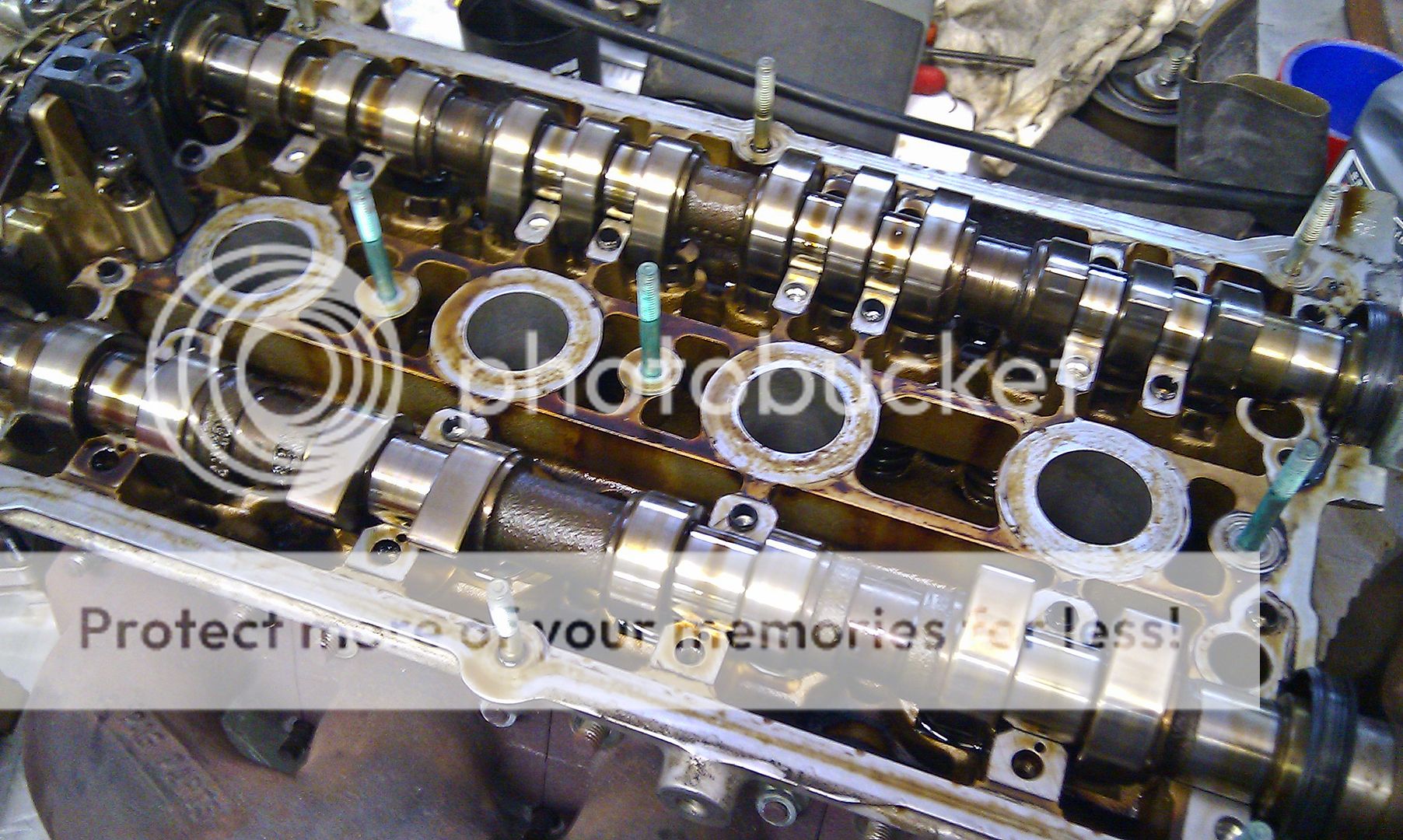

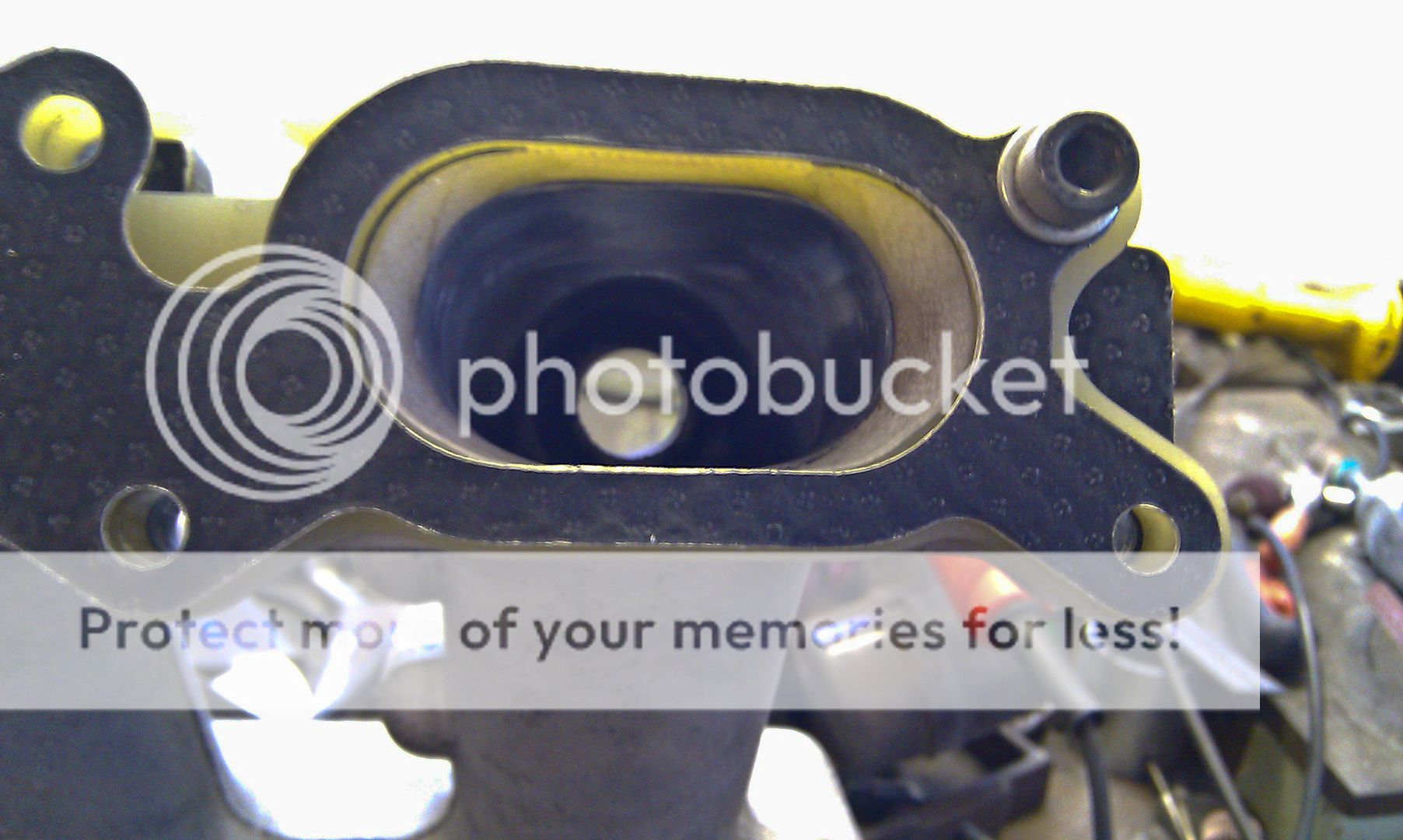

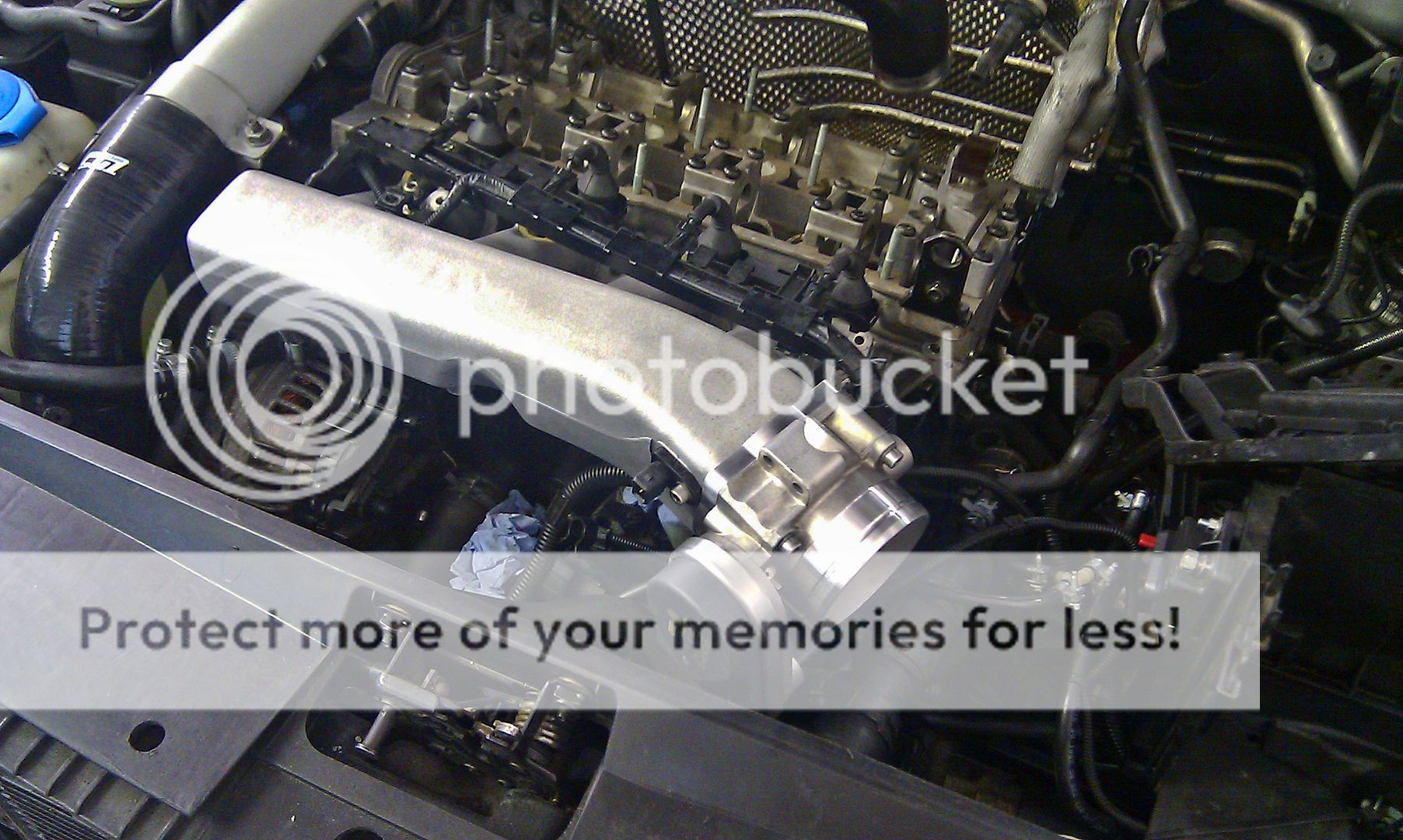

Fitted my inlet mani to a spare head and put that on the engine so I could work out where the pipework would end up...

...awaiting the SFS reducer and 70mm alloy bend...

Now that most of the pipework was in, I though I had better try the bumper again... as I suspected, there was a minor bit of trimming that needed to be done...

This was the same both sides so I marked up the fog light bracket, removed the bumper and trimmed it a little...

Bill is welding the pipes up for me over the next couple of days and welding in a boss for the WMI nozzle ready for when I eventually go WMI...

A lot different from the hoses I removed...

Ideal for someone planning on getting an AH Fabs FMIC :thumbsup:

Remaking the TIP tomorrow and working out where to run the pipework for the supersize DV...

My feet are killing me though... I spend most of my working day sat on my fat ****... this actual working thing is knackering lol

<tuffty/>