mnadeem1984

Registered User

Is there anyway you can test if your n75 valve is faulty using vag-com. Also is it possible to check the MAF sensor? Nothings being flagged up on VagCom....

Tallpaul said:Here's that post again with some more usefull info:

You need to log each of these blocks in 4th gear on a straight, flat piece of road from 2000rpm to the readline (this my take you over the speed limit so i can't condone doing this on a public road)

You can log g/s airflow as a test of the MAF (block 002). You claim 218bhp so a figure of 166 g/s at ~6000rpm would suggest your MAF is OK. If you plot g/s v RPM on a spreadsheet chart the curve should also be fairly smooth.

You can log N75 Duty Cycle, this is how 'open' it's holding the wastegate in % (block 118). This should be a good figure on full boost ie WOT at 3000rpm = ~70%+? Ideally 95% at 3000rpm but that's not hard and fast, really depends on your boost pressure:

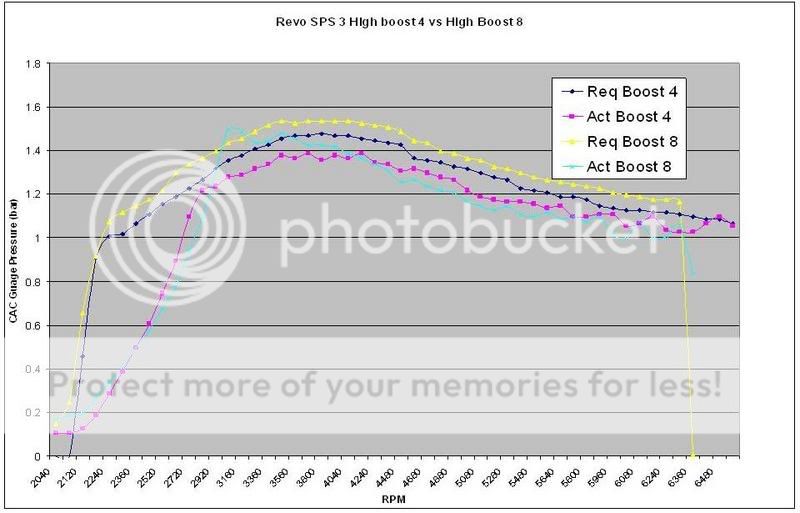

You can also log requested boost and actual boost which is a good check for a leak (block 115). If you requested boost is pretty much meeting actual then your N75 is OK. As for what your actual boost pressure should be... Well lets say your peaking @ 18psi (a sensible number for a remapped K03s)... VAG-COM measures boost in mBar but this figure includes atmospheric pressure so you'd need to apply this calculation: (Boost-1013.25)/1000x14.50377. In other words you'd be looking for a peak boost value of 2300-ish in VAG-COM (assuming you are peaking @ 18psi). If you have a boost gauge then you'll know what you should be getting. Again plotting both requested and actual (2 seperate lines) v RPM on a chart will make it easier to interpret.

squale said:Hi !!

On my ABT S3, Duty cycle is max at 84.3%, does it mean that my N75 F is faulty ? Moreover i have flat spots in boost and the target boost is not reached.. any idead ? (My Maf is ok)

Thx !!!

Tallpaul said:Small boost leak?

Duty cycle is probably ok, but by how much is your actual boost not meeting requested? At most points over the rev range it won't but probably between 4000 - 5000rpm it should be very close.

Tallpaul said:I don't think the N75 is allowed to close the wastegate 100%, one of the many in built safety features of the ECU.

Tallpaul said:Here's that post again with some more usefull info:

You need to log each of these blocks in 4th gear on a straight, flat piece of road from 2000rpm to the readline (this my take you over the speed limit so i can't condone doing this on a public road)

You can log g/s airflow as a test of the MAF (block 002). You claim 218bhp so a figure of 166 g/s at ~6000rpm would suggest your MAF is OK. If you plot g/s v RPM on a spreadsheet chart the curve should also be fairly smooth.

You can log N75 Duty Cycle, this is how 'open' it's holding the wastegate in % (block 118). This should be a good figure on full boost ie WOT at 3000rpm = ~70%+? Ideally 95% at 3000rpm but that's not hard and fast, really depends on your boost pressure:

You can also log requested boost and actual boost which is a good check for a leak (block 115). If you requested boost is pretty much meeting actual then your N75 is OK. As for what your actual boost pressure should be... Well lets say your peaking @ 18psi (a sensible number for a remapped K03s)... VAG-COM measures boost in mBar but this figure includes atmospheric pressure so you'd need to apply this calculation: (Boost-1013.25)/1000x14.50377. In other words you'd be looking for a peak boost value of 2300-ish in VAG-COM (assuming you are peaking @ 18psi). If you have a boost gauge then you'll know what you should be getting. Again plotting both requested and actual (2 seperate lines) v RPM on a chart will make it easier to interpret.

Defratos said:was my boost pressure reading of 12psi sound right?

Defratos said:yeah I think so, Someone on here has told me I'd get a huge difference in pressure between the two ICs. Hopefully gonna be upgrading soon to just the single, maybe that'll sort it out. cheer for the help though

Tallpaul said:12psi sounds spot on to me.

Loftgroover... Are you just altering the boost settings? have your tried playing with the timing too? What fuel and mods do you run?

Tallpaul said:The thing is, the S3 on stock boost doesn't need a FMIC. As your plots show, you are actually losing power because of the extra volume. The two stock SMIC's are very capable of maintaining a sensible inlet temperature.

If i were you, i wouldn't waste more money on expensive mods that give negligable gains. Go get yourself REVO and an SPS3 and keep your FMIC. If you run V-Power then with that FMIC you'll be able to wind up the boost and timing and watch your car fly.

Tallpaul said:Actually, you've probably got an SPS3 v1.1 so try Boost 6/7 Timing 6

and read this: http://www.revotechnik.com/products/pdf/SPS3_advancedUserGuide060406.pdf

loftgroover said:You private user or have business in cambridge?

Tallpaul said:lol, very much an amateur!

loftgroover said:Ha ha, ill start ignoring your advice then