Hi all,

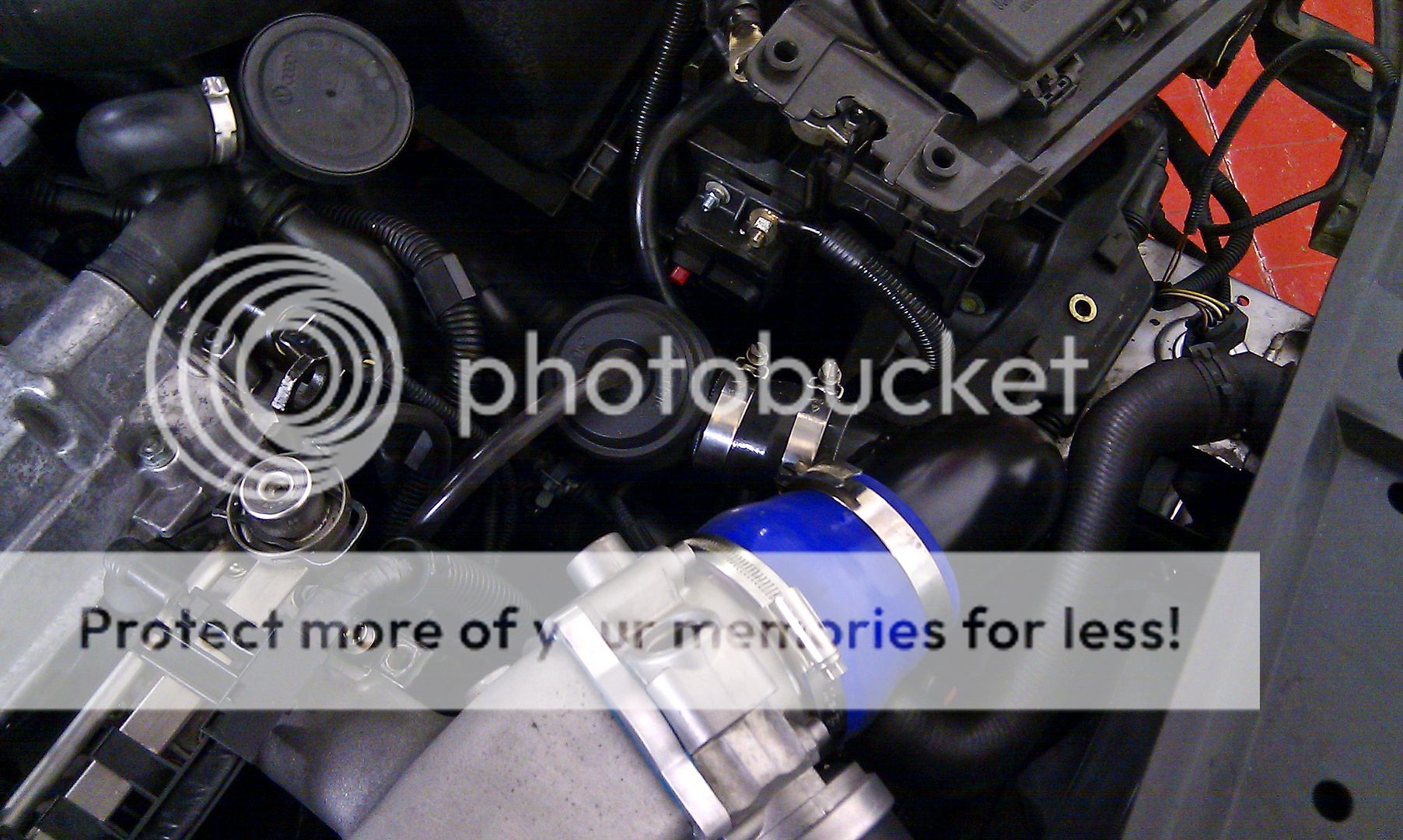

Just wondering if there is any benefit to converting my S3 to a complete alloy hard pipe boost system with silicone joiners?

From what i can gather, it allows a consistently smooth flow and does not expand/retract like silicone hosing does.

I know its not going to give me any major power increases but will aid in 'safer' power when remapped to stage 2 i hope?

Thoughts please?

Shaun.

Just wondering if there is any benefit to converting my S3 to a complete alloy hard pipe boost system with silicone joiners?

From what i can gather, it allows a consistently smooth flow and does not expand/retract like silicone hosing does.

I know its not going to give me any major power increases but will aid in 'safer' power when remapped to stage 2 i hope?

Thoughts please?

Shaun.