- Joined

- Mar 28, 2010

- Messages

- 10,073

- Reaction score

- 2,697

- Points

- 113

- Location

- Liverpool/Southport. N west

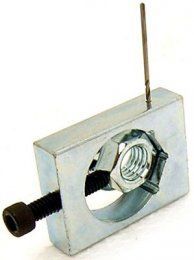

Came across these in my search for little parts.

These are ideal for me tapping my manifold for M10 studs, and space will be very limited, so these requiring a 12mm spanner are ideal:

https://www.merlinmotorsport.co.uk/...ywork-fasteners-and-catches/fastenings/k-nuts

Should make life easier in tight spaces.

These are ideal for me tapping my manifold for M10 studs, and space will be very limited, so these requiring a 12mm spanner are ideal:

https://www.merlinmotorsport.co.uk/...ywork-fasteners-and-catches/fastenings/k-nuts

Should make life easier in tight spaces.