Want to say cheers to Karl for putting the effort in with the comp ratios and how a headgasket will change this as I didn't get round to it and saved me the effort

Little update I have picked internals up from the eng firm (who were probably down the worst road I've ever been down) that done the balancing and its pretty surprising how much have had to remove to get them all to identical weights

Pothole nightmare

Rods

They had to take a tiny bit off of one of the small ends as the rods were balanced end to end

Big ends where can see 3 have been ground on the 45 degree part

Pistons which were surprisingly more uneven weights than I thought they'd be

Closer shot of the piston they removed the most material off

Crank factory balancing drill holes

The material they removed to balance

I then started prepping the block a bit more giving it a thorough clean after all the machining, followed bolting on a couple of bits and bobs but nothing to interesting

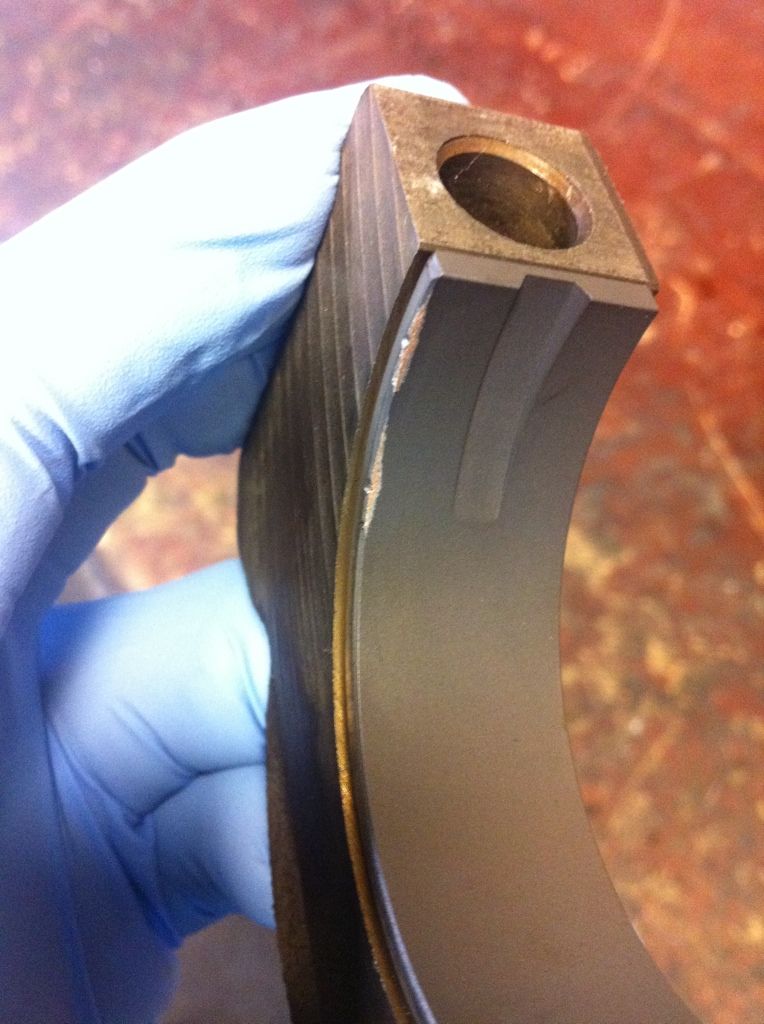

I did then find that one of the bearings had a couple of nicks in it creating a couple of burrs which a little bit of attention with a needle file sorted

I also had a few issues with a rear tie bar but have to say forge customer service has been excellent and they sent me a new set to replace them and will return the old ones to them

Rather cold changing them last night and of coarse dark

Whilst the car was off the road for two days I attacked a couple of other issues....downpipe studs that had wound there self out....again

I changed the front drop links which has got rid of an annoying clonk that has been present for ages which also partially influenced me changing all my front bushes

I had got down to the point I only had 1 interior led working (like a strobe) so checked them to find that a lot of them had died but the festoons had got a bit hot and distorted causing the resistor to not make contact with the end cap

Just moved it round to the other side, refitted the cap and all works again but the littler LEDs for map reading lights are all RIP

Last but not least an embarrassment (cowboyed pikey) heatshield for Bedford knocked up very quickly with tinsnips, bit of steel and a jubilee clip....cue abuse lol