beachbuggy

Registered User

So this isn't your usual hybrid S3 build

This is " how to build a hybrid turbo"

Before anyone says, leave it to the pro's would would like to point out I am fully aware the all the pitfalls and consequences of what can happen if you used a bad turbo, and building a custom turbo is probably a good example. However I have a good knowledge of turbos have built my own and regularly rebuild turbos, with assistance from a good company and have access to a good machine shop.

Believe it or not it's not that difficult and if you can rebuild an engine you can rebuild a turbo.

So today I have just ordered the relevant parts in order to build this hybrid turbo. My aim is to provide those that require or are interested the knowledge to have ago yourself.

Believe it or not Turbo rebuild company's aren't that forth coming in providing part numbers or supplying parts for hybrids! However they seem fine on doing it bog standard k03 etc! And to be honest I'm not surprised.

A little research on google and you can find all the information you need. I struck lucky and found a company in Latvia that listed all the part numbers for all kkk turbos and cross references to other turbos and associated parts. With this knowledge it was very easy to work out what you could build, costings and whether what you planned on doing was possible.

So the k04-020 (k04-023) as used in our s3/TT's in stock it's 225bhp, remapped 265bhp and hybrid 300(+/-)bhp

What does it take to build a hydrid k04?

The whole ideal of a hybrid over say a GT30 is to use the existing components rather than replace manifolds,lines,pipe work etc etc

The hydrid k04 is a k04 turbo with enhanced components, allowing increased performance while retaining stock looks and parts

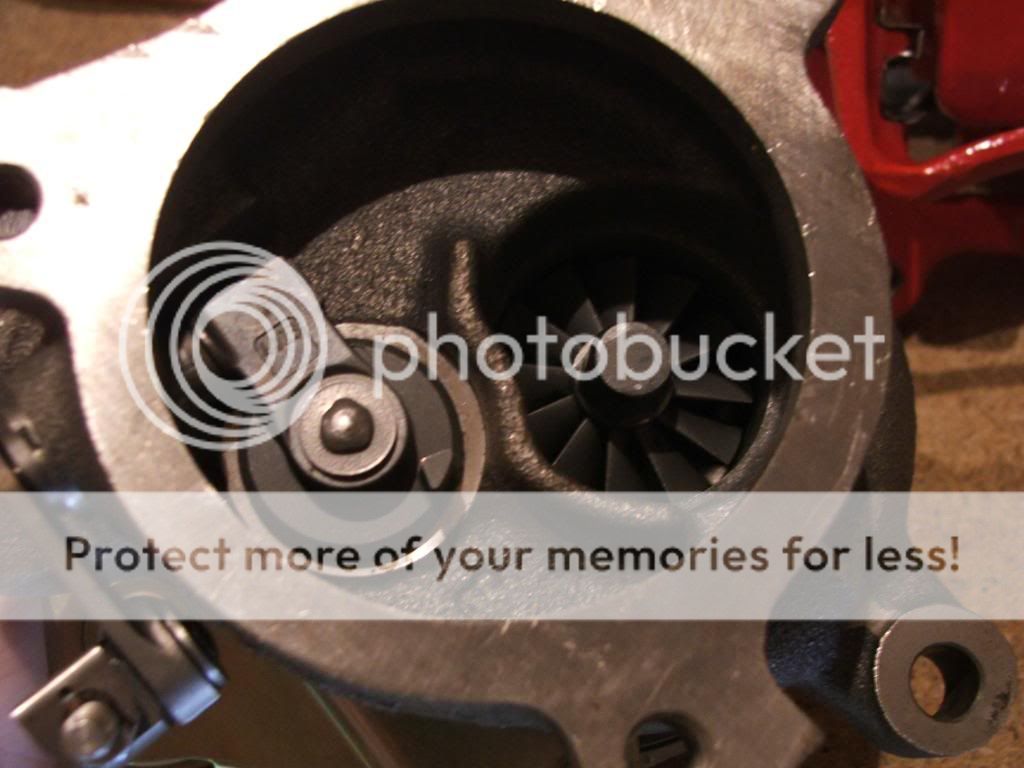

To do this the internals of the turbo must be upgraded, allowing more airflow and he ce more bhp/torque

KKK make all there K03/k04/RS6 turbos with the same internal components, meaning a compressor from a rs6 will fit a k03 exhaust shaft.

So we need to find the largest components we can that will fit inside the k04 housings from our S3's and in order to this machining will need to be done to get the correct tolerances and gaps between and blades and housings. Fortunately again for us the k04 has sufficient metal on the compressor housing and exhaust housing to allow the largest parts KKK sell to fit! Bonus.....

So what can we actually fit inside?

Well anyone who has followed Wellys hybrid build will have seen the pictures of his hybrid. The compressor is listed and classed by most manufactures of hybrids as a k06 compressor wheel. There is no such thing as K06 turbo from which this came from but rather a part number 5306 to which KKK relate it to. The compressor actually is from the new Audi s3 8p. Now many are listed as billet wheels, which means they are machined rather than castes as original KKK ones are made. Here is a good article of billet v Cast compressor wheels

BILLET COMPRESSOR WHEELS

The fact is that these compressor wheels in 2.0tfsi s3 can make 330bhp so any problem with metal creep is a little irrelevant when the aim is to go to 300bhp.

The largest exhaust wheel available is from the RS6 turbos, they in stock form have this larger exhaust turbine mated to the same compressor of our s3. They are also the same exhaust wheel that is used in the VXR turbos so actually commonly available.

Anyone who has seen Bills post showing the compressor comparisons between stock and hybrid K04 will have noticed the difference and to put this in to figures here are the measurements

K04 stock turbo exducer 56.06 inducer 41.86 4/4 blades

K06 turbo exducer 56.06 inducer 46.3 ( although some say it's 60/46) 6/6 blades

Exhaust turbine

Stock exducer 50 inducer 41.92

Rs6 exducer 50 inducer 45

Although these aren't massively bigger they are more efficient and will produce the extra bhp.

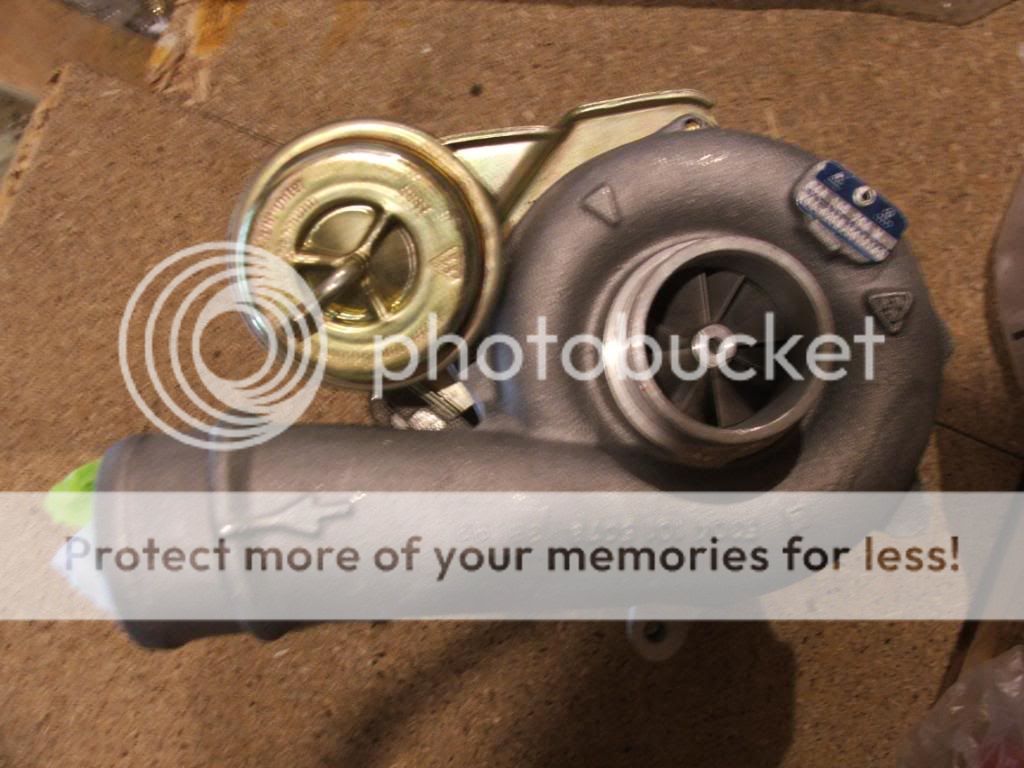

I have bought a good used k04 and the new compressor, turbine and parts are arriving early next week so I will update with pictures and a break down of the turbo and what is planned.

I hope this will be of interest to some

I know it's no use without pictures so I will post some soon

This is " how to build a hybrid turbo"

Before anyone says, leave it to the pro's would would like to point out I am fully aware the all the pitfalls and consequences of what can happen if you used a bad turbo, and building a custom turbo is probably a good example. However I have a good knowledge of turbos have built my own and regularly rebuild turbos, with assistance from a good company and have access to a good machine shop.

Believe it or not it's not that difficult and if you can rebuild an engine you can rebuild a turbo.

So today I have just ordered the relevant parts in order to build this hybrid turbo. My aim is to provide those that require or are interested the knowledge to have ago yourself.

Believe it or not Turbo rebuild company's aren't that forth coming in providing part numbers or supplying parts for hybrids! However they seem fine on doing it bog standard k03 etc! And to be honest I'm not surprised.

A little research on google and you can find all the information you need. I struck lucky and found a company in Latvia that listed all the part numbers for all kkk turbos and cross references to other turbos and associated parts. With this knowledge it was very easy to work out what you could build, costings and whether what you planned on doing was possible.

So the k04-020 (k04-023) as used in our s3/TT's in stock it's 225bhp, remapped 265bhp and hybrid 300(+/-)bhp

What does it take to build a hydrid k04?

The whole ideal of a hybrid over say a GT30 is to use the existing components rather than replace manifolds,lines,pipe work etc etc

The hydrid k04 is a k04 turbo with enhanced components, allowing increased performance while retaining stock looks and parts

To do this the internals of the turbo must be upgraded, allowing more airflow and he ce more bhp/torque

KKK make all there K03/k04/RS6 turbos with the same internal components, meaning a compressor from a rs6 will fit a k03 exhaust shaft.

So we need to find the largest components we can that will fit inside the k04 housings from our S3's and in order to this machining will need to be done to get the correct tolerances and gaps between and blades and housings. Fortunately again for us the k04 has sufficient metal on the compressor housing and exhaust housing to allow the largest parts KKK sell to fit! Bonus.....

So what can we actually fit inside?

Well anyone who has followed Wellys hybrid build will have seen the pictures of his hybrid. The compressor is listed and classed by most manufactures of hybrids as a k06 compressor wheel. There is no such thing as K06 turbo from which this came from but rather a part number 5306 to which KKK relate it to. The compressor actually is from the new Audi s3 8p. Now many are listed as billet wheels, which means they are machined rather than castes as original KKK ones are made. Here is a good article of billet v Cast compressor wheels

BILLET COMPRESSOR WHEELS

The fact is that these compressor wheels in 2.0tfsi s3 can make 330bhp so any problem with metal creep is a little irrelevant when the aim is to go to 300bhp.

The largest exhaust wheel available is from the RS6 turbos, they in stock form have this larger exhaust turbine mated to the same compressor of our s3. They are also the same exhaust wheel that is used in the VXR turbos so actually commonly available.

Anyone who has seen Bills post showing the compressor comparisons between stock and hybrid K04 will have noticed the difference and to put this in to figures here are the measurements

K04 stock turbo exducer 56.06 inducer 41.86 4/4 blades

K06 turbo exducer 56.06 inducer 46.3 ( although some say it's 60/46) 6/6 blades

Exhaust turbine

Stock exducer 50 inducer 41.92

Rs6 exducer 50 inducer 45

Although these aren't massively bigger they are more efficient and will produce the extra bhp.

I have bought a good used k04 and the new compressor, turbine and parts are arriving early next week so I will update with pictures and a break down of the turbo and what is planned.

I hope this will be of interest to some

I know it's no use without pictures so I will post some soon

Last edited:

i would want more than 300 bhp from a hybrid though, im expecting 340-350bhp with large port and WMI

i would want more than 300 bhp from a hybrid though, im expecting 340-350bhp with large port and WMI