Morning all.

It seems there may be a potential problem with the post intercooler WMI setup often used, including by myself...

There is a possibility, and it's not for definite, that the Methanol over a period of time can eat through the Throttle Body's seals to the electronics.

Methanol is well know for being corrosive to rubber seals - Methanol Molecule - hence why if you were going to run a car on Meth alone, you would have some serious work to do...

Anyway, Bumble packed up yesterday morning, and wouldn't even idle, let alone get me to work. EPC light was on on the dash and there was no throttle response at all from the pedal. Checked for fault codes using liquid and got 17976 - Throttle Body Mechanical Malfunction.

Bearing in mind, the largest amount of meth I have ever used in one go went through the engine on Saturday round the track at Castle Combe, Bill suggest that that the above may be the cause.... and it would seem he is right unsurprisingly.

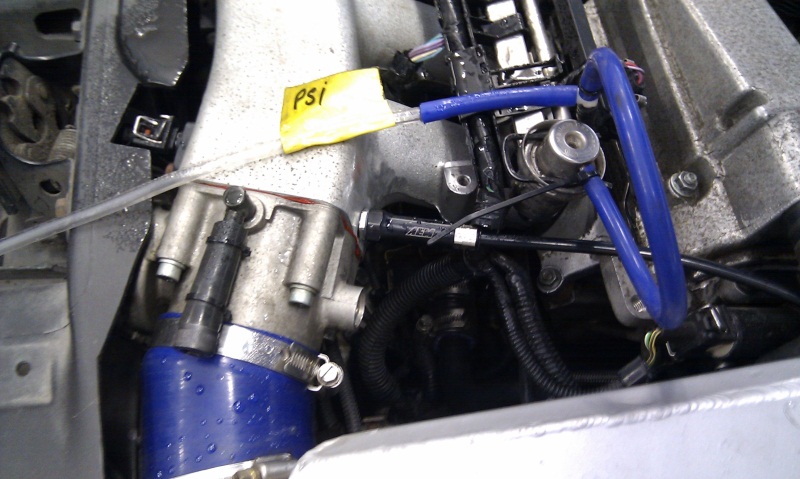

Little droplets of liquid, unconfirmed what, all under the electronics board and visible on the plastic in the photo above.

It's unclear exactly what happens here.

There are two possibilities:

1: The water/meth is still liquid in the charge air at the point it gets to the throttle body. This should be the case as it should be evaporated. If so, the liquid may be literally eating through the seal. Should be reasonable to resolve.

2: The water/meth does evaporate properly as expected, but the methanol even evaporated is still corrosive enough to eat the seal, air gets through the perished seal, and the condensates when the engine gets cold. Result, water in the electrics.

I would say based on what happen to my TB, that the second is most likely. I parked it up the night before and turned it off. When I started it up again, the TB was dead, so condensation of air is definitely possible. IMO.

Now, my TB is as old as the Cotswolds and has done a million miles, so I'm not saying that this will always happen to others. The seal may well have been old and knackered anyway, and this was always going to happen.

Throttle bodies do just fail, my mate had one go a few months ago running a stock S3 with no meth at all.

Coincidence? Possibly.

I am thinking about how I plan to future proof a TB on an engine running meth... :-/

It seems there may be a potential problem with the post intercooler WMI setup often used, including by myself...

There is a possibility, and it's not for definite, that the Methanol over a period of time can eat through the Throttle Body's seals to the electronics.

Methanol is well know for being corrosive to rubber seals - Methanol Molecule - hence why if you were going to run a car on Meth alone, you would have some serious work to do...

Anyway, Bumble packed up yesterday morning, and wouldn't even idle, let alone get me to work. EPC light was on on the dash and there was no throttle response at all from the pedal. Checked for fault codes using liquid and got 17976 - Throttle Body Mechanical Malfunction.

Bearing in mind, the largest amount of meth I have ever used in one go went through the engine on Saturday round the track at Castle Combe, Bill suggest that that the above may be the cause.... and it would seem he is right unsurprisingly.

Little droplets of liquid, unconfirmed what, all under the electronics board and visible on the plastic in the photo above.

It's unclear exactly what happens here.

There are two possibilities:

1: The water/meth is still liquid in the charge air at the point it gets to the throttle body. This should be the case as it should be evaporated. If so, the liquid may be literally eating through the seal. Should be reasonable to resolve.

2: The water/meth does evaporate properly as expected, but the methanol even evaporated is still corrosive enough to eat the seal, air gets through the perished seal, and the condensates when the engine gets cold. Result, water in the electrics.

I would say based on what happen to my TB, that the second is most likely. I parked it up the night before and turned it off. When I started it up again, the TB was dead, so condensation of air is definitely possible. IMO.

Now, my TB is as old as the Cotswolds and has done a million miles, so I'm not saying that this will always happen to others. The seal may well have been old and knackered anyway, and this was always going to happen.

Throttle bodies do just fail, my mate had one go a few months ago running a stock S3 with no meth at all.

Coincidence? Possibly.

I am thinking about how I plan to future proof a TB on an engine running meth... :-/