so, today!

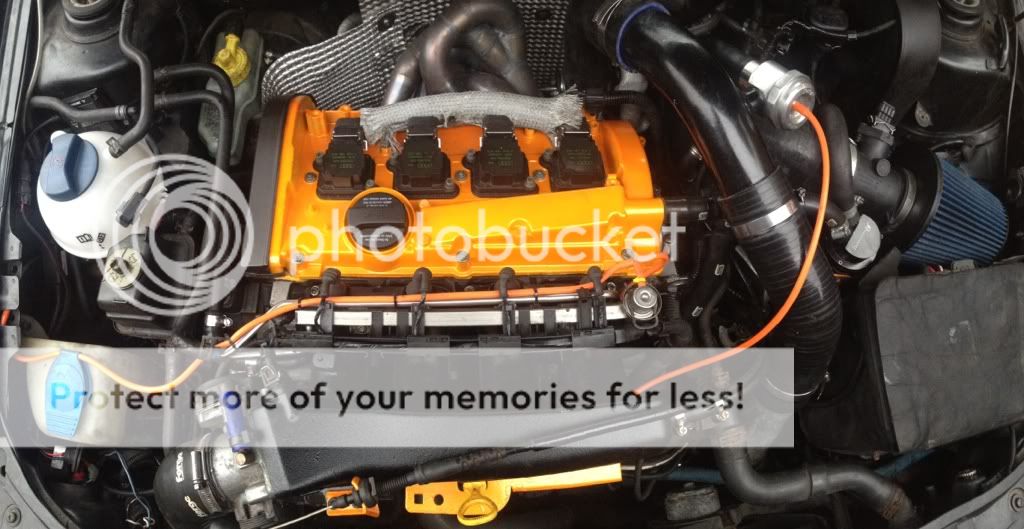

I started today by fitting a few boost hoses before the front end went on, which remidned me I'd forgotten to tap a thread into the rocker cover to hold my heat shield:

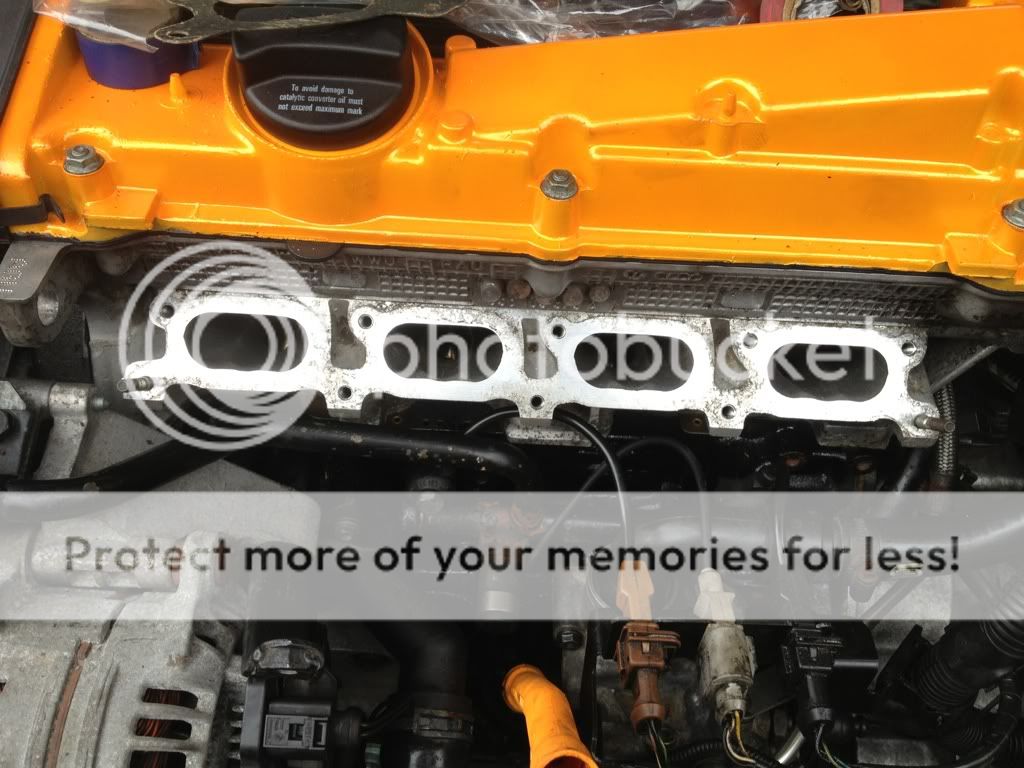

Random pic of the phenolic spacer from underneath:

Added a few more boost hoses, plus the TIP and the MAF, as well as the forge DV freshly rebuilt with new grease and the piston lapped in to ensure a good seal.

Then it was time to install the slam panel:

Followed by the intercooler core:

Cold side pipework with Methanol connection:

Even my hose clips and IC core have Nurburgring barrier scars!

So, the big moment!

I unplugged the injectors and ICM to be sure it couldn't fire, and cranked it over.

All sounded well, so I decided to crank it one more time, and then plug it all in and see what happened!

The result:

<a href="http://www.youtube.com/watch?v=r2JP5bATZLw" target="_blank">

It lives! But it sounded terrible. Top end was very tappey, not impressed at all.

A quick chat to Tuffty, and he suggested taking the rocker cover off to check oil was getting to the top end. So off it came.

Definitely oil in here:

I poured oil over the top of the cams, and refitted the cover, and fired it up on Tufftys advice and let it warm up.

Thankfully, as it warmed up, the noise went away, and has now gone totally

THANK GOD FOR THAT!!!! I was pretty worried at first.

With the engine running and me feeling happier, It was time to bleed the brakes and clutch so I could take it for a drive.

I used the ATE super blue fluid that Frenchman gave me for my birthday

Hooked up the pressure bleeder:

Handy having a million spare wheels lying around for the EZbleed:

And she's finished!

Time to put the nose back on so it looks like a car again:

And the sorry looking rattle canned bumper:

And it's a car again!

Hopefully not too long before we can use these again

Very happy with how it's looking too:

I went for a test drive, and within a few hundred yards it was missfiring badly and felt pretty ****

I limped it back home, whipped off the coilpacks and injector plugs, and cleaned up all the terminals, as well as the MAF plug, and WD40'd the whole lot and put it back together.

I went back out, and it still felt a little off song, I decided to try putting my foot down a bit to see what happened, and it cleared totally! Woohoo!!!!

I came back home, and nipped into town in the Megane to pick Tori up from work. I took her round to show her my work when we got home, and the first thing she noticed was a trail of oil running down the drive

******. I can smell gearbox oil!

<a href="http://www.youtube.com/watch?v=OfV0uTd9uss" target="_blank">

****, not ideal, but thankfully an easy simple fix.

that's why I've recently bought 2 sets of Mintex 1177 front pads, a set of mintex 1155 rear pads, some alloy trumpet intakes to go in the front grilles, and 3m of 63mm neoprene ducting.