Another hybrid conversion thread....

- Thread starter Welly

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AudiS3-Turbo

Registered User

Just been reading your thread and you have been through some ****! you are a trooper for sticking in there god knows many others would have thrown the towel in by now.

Just been reading your thread and you have been through some ****! you are a trooper for sticking in there god knows many others would have thrown the towel in by now.

lol, I've had a few beers with the missus

Not giving up on the hybrid just yet. I think 340 BHP is achievable, and be damned if I am going to stop before I get it.

By the power of Greyskull....

- Joined

- Jun 19, 2009

- Messages

- 3,883

- Reaction score

- 619

- Points

- 113

- Location

- Leeds

- Website

- www.aldevelopments.com

Not tempted in the TSR manifold then? OK i know its £600+vat but it looks a well made manifold and from what i see its made of stainless butt weld pipe thats over 3mm thick

After seen all the trouble you have been though thats why i'm going to sell my CR Hybrid and go BT myself depending on money as i would love to go GT35 but the GT30 are a tad cheaper and lag isn't going to be much of a problem with me anyway

After seen all the trouble you have been though thats why i'm going to sell my CR Hybrid and go BT myself depending on money as i would love to go GT35 but the GT30 are a tad cheaper and lag isn't going to be much of a problem with me anyway

Dane

Had an 8L S3, a B5 RS4 now I have a B8 S4

Not tempted in the TSR manifold then? OK i know its £600+vat but it looks a well made manifold and from what i see its made of stainless butt weld pipe thats over 3mm thick

After seen all the trouble you have been though thats why i'm going to sell my CR Hybrid and go BT myself depending on money as i would love to go GT35 but the GT30 are a tad cheaper and lag isn't going to be much of a problem with me anyway

The problem is dude, that by the time it is available on the market, VAT will have gone up to 20% I would imagine, making the cost £720 plus shipping.

I can go on holiday for 2 weeks for that!! lol.

The JBS manifold is mildly more palatable at £450.

WMI will be needed as well, and have bits to get for that, so add more doshola. Looking at another £1000 by the time both are done and fitted.

Ouch.

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Im getting the header lazer cut and a local exhaust specialist is making up the tubes, and fabricating it. Ive told him to keep all measurements if it runs well, so he can replicate, im paying quite a premium for it making, but it will be my manifold for further production...

this sounds interesting.. low angle merge collector type design being employed?

any info on what they're proposing?

Some interesting info here on the 034:

The Audi TT Forum :: View topic - 034 Motorsport TT/S3 K04 manifold upgrade

Apparently it's made from 'Similar' material to the OEM manifold. And can withstand 900c sustained EGTS.

The Audi TT Forum :: View topic - 034 Motorsport TT/S3 K04 manifold upgrade

Apparently it's made from 'Similar' material to the OEM manifold. And can withstand 900c sustained EGTS.

Last edited:

For those who don't know about the JBS manifold (I'm sure most of you do), here is the data as it stands.

NEW JBS K04 OEM Upgrade Cast Manifold - JBS

NEW JBS K04 OEM Upgrade Cast Manifold - JBS

Speedy Steve

Registered User

good on you welly for sticking with it ive been in a similar situation as you when i first did a 1.8vvc engine in a metro but i stuck it out and ended up with a 230bhp metro! Id have been in the same boat as you if id have had the spare cash so i thank you for saving me money!

good on you welly for sticking with it ive been in a similar situation as you when i first did a 1.8vvc engine in a metro but i stuck it out and ended up with a 230bhp metro! Id have been in the same boat as you if id have had the spare cash so i thank you for saving me money!

That does make the sting better I must admit. That's the whole point of forums such as this to be fair, to help one another out and learn from mistakes/ideas/tests that have already been made/done.

I like to think that my problems will help other avoid the same issues in the future.

RobbieRolex

Registered User

Some interesting info here on the 034:

The Audi TT Forum :: View topic - 034 Motorsport TT/S3 K04 manifold upgrade

Apparently it's made from 'Similar' material to the OEM manifold. And can withstand 900c sustained EGTS.

I would love to know who provided the information that it can function within 900c sustained temps, i have asked INA and 034 this same question at least 5 times and they all dance around the question, i still have not got an answer from them!!!!!!

I would love to know who provided the information that it can function within 900c sustained temps, i have asked INA and 034 this same question at least 5 times and they all dance around the question, i still have not got an answer from them!!!!!!

I liked the "It's made from similar material to OEM". As in what? The fact its made of metal as opposed to wood?

My garden spade is made from similar material to the OEM manifold. As are my bathroom taps.

Strangely neither of the above are good as exhaust manifolds either.

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Some interesting info here on the 034:

The Audi TT Forum :: View topic - 034 Motorsport TT/S3 K04 manifold upgrade

Apparently it's made from 'Similar' material to the OEM manifold. And can withstand 900c sustained EGTS.

Hmmm yea, apart from when it cant..

its not melted - its cracked

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

I would love to know who provided the information that it can function within 900c sustained temps, i have asked INA and 034 this same question at least 5 times and they all dance around the question, i still have not got an answer from them!!!!!!

thats says it all does'nt it.

how can you trust them and the manifold when they wont answer straight?

there's too much evasion going on to have confidence

Here are a selection of graphs from last night.

The first is a comparison between the Ported K04 manifold, and the 034.

The second is a selection of runs.

The first is a comparison between the Ported K04 manifold, and the 034.

The second is a selection of runs.

Right. Important post this one so everyone read it....lol.

I think this is a good time to try and de-merge the lines that have been blurred a little.

The results from last night are a direct result of the exhaust manifold being changed.

I am trying to remove the thought that, because of this, the 3" TIP isn't as effective a mod as it may have looked initially.

This really isn't the case.

The G/S air inbound with my Forge TIP were 245 - 250 g/s. They are now 265+ g/s. There is no doubt whatsoever that the TIP has made a big difference is all aspects of the engine.

G/S flow rate is higher. EGTs are reduced. Boost is held far better at the top end that it was previously.

The problem that I now have is to do with getting the gasses out of the engine, as there is now no restriction on the way in.

This problem is also amplified by the feature of a large port head, as EGTs appear to be higher due to increased flow.

This a problem that would appear to be very specific to my car (irritatingly ).

).

Standard manifold with 3" TIP is making more power than without. Around 5 BHP or there abouts, not to mention the other benefits. A worthwhile mod in anyone's book.

I think this is a good time to try and de-merge the lines that have been blurred a little.

The results from last night are a direct result of the exhaust manifold being changed.

I am trying to remove the thought that, because of this, the 3" TIP isn't as effective a mod as it may have looked initially.

This really isn't the case.

The G/S air inbound with my Forge TIP were 245 - 250 g/s. They are now 265+ g/s. There is no doubt whatsoever that the TIP has made a big difference is all aspects of the engine.

G/S flow rate is higher. EGTs are reduced. Boost is held far better at the top end that it was previously.

The problem that I now have is to do with getting the gasses out of the engine, as there is now no restriction on the way in.

This problem is also amplified by the feature of a large port head, as EGTs appear to be higher due to increased flow.

This a problem that would appear to be very specific to my car (irritatingly

Standard manifold with 3" TIP is making more power than without. Around 5 BHP or there abouts, not to mention the other benefits. A worthwhile mod in anyone's book.

Replacement 032 motorsport manifold arrived today, and is now on ebay.

Please - no-one buy it!! Link attached for reference only, just in case you happen upon it.

K04 High Flow 034 Motorsport manifold - Audi S3/1.8T on eBay (end time 29-Nov-10 22:11:30 GMT)

Please - no-one buy it!! Link attached for reference only, just in case you happen upon it.

K04 High Flow 034 Motorsport manifold - Audi S3/1.8T on eBay (end time 29-Nov-10 22:11:30 GMT)

RobbieRolex

Registered User

Why is the 034 rubbed off?

That is a VERY good question....

RobbieRolex

Registered User

Jez, if they had confidence in this product i would have thought they would want every one to know its a 034 product, or it could be a reworked 2nd.

RobbieRolex

Registered User

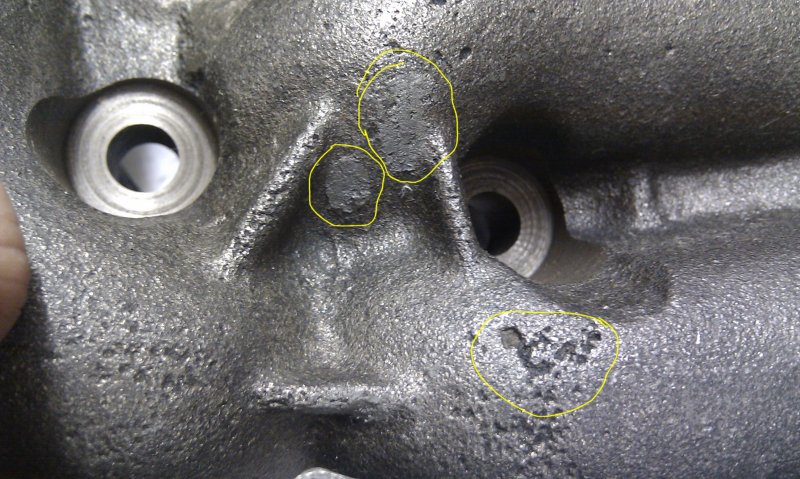

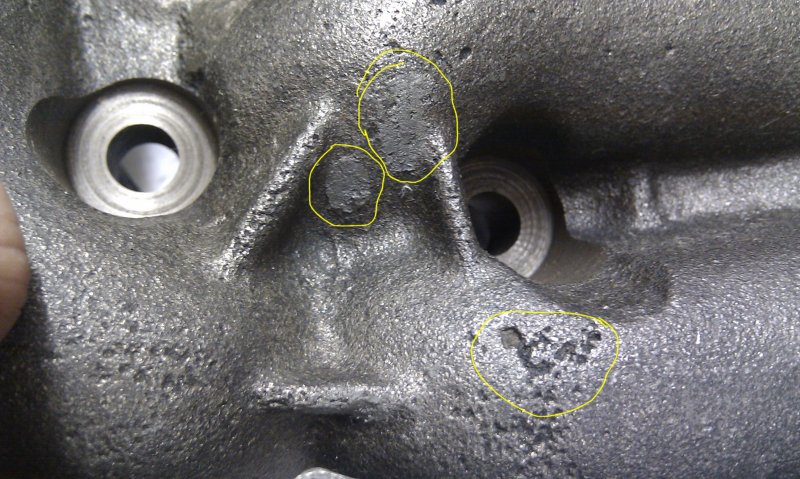

Here is what happened to the crack in runner #4 when heated up....

Can anyone spot the slight difference in the material? Clue: The heat gives it away a little....

Can anyone spot the slight difference in the material? Clue: The heat gives it away a little....

- Joined

- Nov 11, 2009

- Messages

- 10,099

- Reaction score

- 739

- Points

- 38

- Location

- west yorks

- Website

- www.stainless-engineering.co.uk

The material is not uniform so it will have hot spots, and parts will cool down quicker than others, not good for cast....

RobbieRolex

Registered User

The material is not uniform so it will have hot spots, and parts will cool down quicker than others, not good for cast....

Precisely.... And what happens? Crackage....

So what does this tell us, poor raw materials? or the process for casting the mani?

Yeah, basically both of the above.

Nowhere near as high quality as the OEM gear as was proven when Bill tried to weld it to see what would happen.

The OEM cast responded well to it, the 034 fell apart.

RobbieRolex

Registered User

Hmmmmm, thats not too good, my next question would be, is this a once off and you were just unlucky enough to get a faulty manifold or could this test be replicated on another 034 mani.

Surely 034/INA have some response to this?

Surely 034/INA have some response to this?

Hmmmmm, thats not too good, my next question would be, is this a once off and you were just unlucky enough to get a faulty manifold or could this test be replicated on another 034 mani.

Surely 034/INA have some response to this?

I was tempted to test the second one I have, however didn't want to risk damaging it. I am dependant on the money from it for other things....

hmmmm so the quailty of the material is poor, but the manifold itself proved to be an improvement in terms of flow. Could you not use the manifold to have a new one recast with a quailty material?

hmmmm so the quailty of the material is poor, but the manifold itself proved to be an improvement in terms of flow. Could you not use the manifold to have a new one recast with a quailty material?

Cost implications of reverse engineering it to the point you could do that would be a lot sadly.

There will be other products on the market soon that will be worth buying. The JBS one springs to mind as it's what I would deem to be an affordable price bracket.

Looking to past products, the JBS K03 manifold was very good, where as the 034 K04 manifold cracked (surprise surprise).

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

Right..

I had a look at the 034 k04 mani which came off Wellys S3 last week last night.

The replacement arrived yesterday (thankyou Issam), however there are some worrying aspects about the cracked one and its replacement.

see below.. make your own conclusions

1st thing was to attempt a repair to the crack on #4 runner, preheating the manifold before hand.. with a very odd heat pattern. Only one side of the cracked manifold would heat up as seen... the other side would not get to an even temp. Some very odd material in this section, and or wall thickness, so no surprise at all there is a large stress raiser if one side glows red easily whilst the other does'nt.. Differential expension = Crack!

Once welded it looked like this.

The melting point of the material was Very Low. Very few amps were requried before this material puddled and sank..a strange soft material with a low melting point.. Way less than a std factory manifold which I also weld repaired to try and compare known ok quality vs 034.

K03 repaired crack below. Also preheated with the same blow torch and it would not glow at all unlike the 034 which glowed easily on its one side of the crack?

Now the other runner crack was attempted to weld repair, with resultant epic fail. Again the material when pooled had all manner of slag rising out of the material, and aa very low ampage was required to melt the parent material. No matter what I tried with pre-heating with the torch, as soon as the castign started to cool, it would Tink, Tink and a crack reappeared next to the weld.

Point to mention here is this Tink Tink is the exact same sound Welly reported the manifold made on cooling down after first being fitted. Castings should not make this noise, its contracting and cracking when it does.

For the crack to reappear next to the heat affected zone adjacent to the weld is not uncommon, however, it would just not stop, and finally a portion away from the welded section also broke/cracked, so I called it a day. The thing is simply made from very poor material, and has serious manufacturing issues and defects.

Cracked again near the welded bit..

The New Replacement (issues)

As delivered, curious as to why 034 Motorsport had been badly ground off? Why would someone do this?

And the issues on the new manifold.. Porosity, chemical metal filled? ? ?

Pictures of area's in question which look filled to me with a material which looks like chemical metal. surely not..

The material these are cast from is nothing like as high temp as a factory manifold. Simple test of ampage on the tig welder and blow torch confirm this. The debris coming out of the 034 manifold when welding confirms the material is poor and contaminated. The casting shows significant porosity also, and on the replacement, what looks like a vein attempt to "fill" some cavity with a material? Remember these manifolds see >900'C temps in normal service.

I am absolutely stunned at the abysmal quality of these 034 manifolds. Very poor material choice (cheap) has ruined what could have been a good product. Casting issues also very evident with respect to the prorosity seen. totally unacceptable to me, for anyone to be offering these for sale. There is no way simply ceramic coating the manifolds will remedy the inherant issues evident on the 2 I have seen.

Shocked.. and extremely dissapointed in all concerned offering these to folks and taking their money for them!

I had a look at the 034 k04 mani which came off Wellys S3 last week last night.

The replacement arrived yesterday (thankyou Issam), however there are some worrying aspects about the cracked one and its replacement.

see below.. make your own conclusions

1st thing was to attempt a repair to the crack on #4 runner, preheating the manifold before hand.. with a very odd heat pattern. Only one side of the cracked manifold would heat up as seen... the other side would not get to an even temp. Some very odd material in this section, and or wall thickness, so no surprise at all there is a large stress raiser if one side glows red easily whilst the other does'nt.. Differential expension = Crack!

Once welded it looked like this.

The melting point of the material was Very Low. Very few amps were requried before this material puddled and sank..a strange soft material with a low melting point.. Way less than a std factory manifold which I also weld repaired to try and compare known ok quality vs 034.

K03 repaired crack below. Also preheated with the same blow torch and it would not glow at all unlike the 034 which glowed easily on its one side of the crack?

Now the other runner crack was attempted to weld repair, with resultant epic fail. Again the material when pooled had all manner of slag rising out of the material, and aa very low ampage was required to melt the parent material. No matter what I tried with pre-heating with the torch, as soon as the castign started to cool, it would Tink, Tink and a crack reappeared next to the weld.

Point to mention here is this Tink Tink is the exact same sound Welly reported the manifold made on cooling down after first being fitted. Castings should not make this noise, its contracting and cracking when it does.

For the crack to reappear next to the heat affected zone adjacent to the weld is not uncommon, however, it would just not stop, and finally a portion away from the welded section also broke/cracked, so I called it a day. The thing is simply made from very poor material, and has serious manufacturing issues and defects.

Cracked again near the welded bit..

The New Replacement (issues)

As delivered, curious as to why 034 Motorsport had been badly ground off? Why would someone do this?

And the issues on the new manifold.. Porosity, chemical metal filled? ? ?

Pictures of area's in question which look filled to me with a material which looks like chemical metal. surely not..

The material these are cast from is nothing like as high temp as a factory manifold. Simple test of ampage on the tig welder and blow torch confirm this. The debris coming out of the 034 manifold when welding confirms the material is poor and contaminated. The casting shows significant porosity also, and on the replacement, what looks like a vein attempt to "fill" some cavity with a material? Remember these manifolds see >900'C temps in normal service.

I am absolutely stunned at the abysmal quality of these 034 manifolds. Very poor material choice (cheap) has ruined what could have been a good product. Casting issues also very evident with respect to the prorosity seen. totally unacceptable to me, for anyone to be offering these for sale. There is no way simply ceramic coating the manifolds will remedy the inherant issues evident on the 2 I have seen.

Shocked.. and extremely dissapointed in all concerned offering these to folks and taking their money for them!

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

So what does this tell us, poor raw materials? or the process for casting the mani?

BOTH - its abysmal

wow, considering the pitting and obvious repairs to Wellys replacement item and that the 034 Motorsport stamp has been removed do you think they may have sent a factory reject to replace Welly's original duff item?

- Joined

- May 28, 2004

- Messages

- 10,217

- Reaction score

- 2,385

- Points

- 113

- Location

- nr Glos

- Website

- www.badger5.co.uk

- Joined

- Nov 11, 2009

- Messages

- 10,099

- Reaction score

- 739

- Points

- 38

- Location

- west yorks

- Website

- www.stainless-engineering.co.uk

It seems to me they want to disassociate with the manifold. but not the money people are paying for these.

They have obviously spent alot of cash designing it and skimpt out where it matters... on the quality of the metals.

They have obviously spent alot of cash designing it and skimpt out where it matters... on the quality of the metals.

OMG

Very good post Bill.

Has issam been pointed towards this post?

My £100 Chinese cheapy log mani is better made than this £400 manim it's unbelieveable

Very good post Bill.

Has issam been pointed towards this post?

My £100 Chinese cheapy log mani is better made than this £400 manim it's unbelieveable